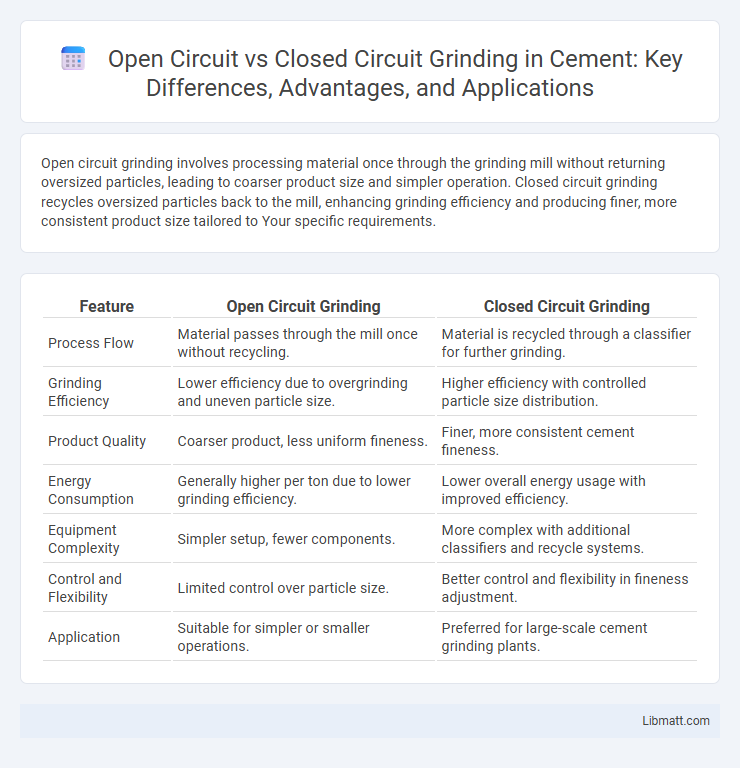

Open circuit grinding involves processing material once through the grinding mill without returning oversized particles, leading to coarser product size and simpler operation. Closed circuit grinding recycles oversized particles back to the mill, enhancing grinding efficiency and producing finer, more consistent product size tailored to Your specific requirements.

Table of Comparison

| Feature | Open Circuit Grinding | Closed Circuit Grinding |

|---|---|---|

| Process Flow | Material passes through the mill once without recycling. | Material is recycled through a classifier for further grinding. |

| Grinding Efficiency | Lower efficiency due to overgrinding and uneven particle size. | Higher efficiency with controlled particle size distribution. |

| Product Quality | Coarser product, less uniform fineness. | Finer, more consistent cement fineness. |

| Energy Consumption | Generally higher per ton due to lower grinding efficiency. | Lower overall energy usage with improved efficiency. |

| Equipment Complexity | Simpler setup, fewer components. | More complex with additional classifiers and recycle systems. |

| Control and Flexibility | Limited control over particle size. | Better control and flexibility in fineness adjustment. |

| Application | Suitable for simpler or smaller operations. | Preferred for large-scale cement grinding plants. |

Introduction to Grinding Circuits

Grinding circuits are fundamental to mineral processing, with open circuit grinding allowing material to pass through the mill once without classification, achieving a coarser product size. Closed circuit grinding incorporates classifiers or screens to return oversized particles for regrinding, improving efficiency and producing a finer, more uniform product. Understanding your grinding circuit type optimizes throughput and energy consumption in crushing and milling operations.

What is Open Circuit Grinding?

Open Circuit Grinding is a process where the material passes through the grinding mill once without any return for further grinding, resulting in a product with a broader particle size distribution. This method is often preferred for its simplicity and higher throughput, but it can produce coarser output compared to closed circuit systems. It is commonly used in applications where precise particle size control is less critical.

What is Closed Circuit Grinding?

Closed circuit grinding is a process where the material passes through the mill and then separated by a classifier, with oversized particles returned to the mill for further grinding. This method increases grinding efficiency by continuously recycling coarse particles, ensuring a finer and more uniform product size. You benefit from improved control over particle size distribution and reduced energy consumption compared to open circuit grinding.

Key Differences Between Open and Closed Circuit Grinding

Open circuit grinding involves the material passing through the mill only once without classification, resulting in coarser particle size and lower efficiency. Closed circuit grinding recycles oversize particles back to the mill via a classifier, improving product uniformity, fineness, and energy efficiency. Your choice depends on desired particle size distribution and energy optimization in the grinding process.

Advantages of Open Circuit Grinding

Open circuit grinding offers improved process flexibility by allowing particles to pass through the mill in a single pass, which reduces the risk of over-grinding and enhances throughput capacity. This method decreases energy consumption per unit of material because the absence of a separator leads to simpler operation and lower maintenance costs. Open circuit systems are particularly advantageous for coarse grinding applications requiring straightforward processing and reduced operational complexity.

Advantages of Closed Circuit Grinding

Closed circuit grinding offers significant advantages in achieving precise particle size control and improving product consistency. By continuously monitoring and recycling oversized material through a classifier or screen, it reduces energy consumption and enhances grinding efficiency. Your operations benefit from lower production costs and higher quality output with closed circuit grinding systems.

Disadvantages of Each Grinding Circuit

Open circuit grinding results in reduced efficiency due to the lack of classification, causing overgrinding and higher energy consumption as the material passes through the mill only once before discharge. Closed circuit grinding presents challenges such as increased complexity and maintenance requirements from the use of classifiers or cyclones to separate fine and coarse particles, and potential blockages in the recirculating load can reduce throughput. Both circuits face issues related to product size control, with open circuits producing less uniform particle sizes and closed circuits requiring precise control systems to avoid process instability.

Applications in Industry: When to Use Open or Closed Circuit

Open circuit grinding is ideal for removing large amounts of material quickly in industries such as metal fabrication and rough machining, where precision is less critical. Closed circuit grinding is preferred in fine finishing processes found in automotive, aerospace, and tool manufacturing, where tight size control and surface finish consistency are essential. Selecting between open and closed circuit depends on the balance between material removal rate and product quality requirements in manufacturing workflows.

Energy Efficiency: Open vs. Closed Circuit Grinding

Closed circuit grinding improves energy efficiency by recirculating oversized particles back to the mill for further size reduction, reducing energy waste. Open circuit grinding consumes more energy as all material passes through the mill once without classification or recirculation, leading to less precise particle sizes and higher power usage. Optimizing grinding circuit type directly affects your energy costs and milling performance in mineral processing operations.

Choosing the Right Grinding Circuit for Your Operation

Choosing the right grinding circuit for your operation involves understanding the differences between open circuit and closed circuit grinding. Open circuit grinding allows material to pass through the mill without classification, suitable for less precise particle size requirements and simpler setups. Closed circuit grinding recycles coarse particles through a classifier back into the mill, enhancing efficiency and product size control, making it ideal for operations demanding high throughput and consistent product quality.

Open Circuit vs Closed Circuit Grinding Infographic

libmatt.com

libmatt.com