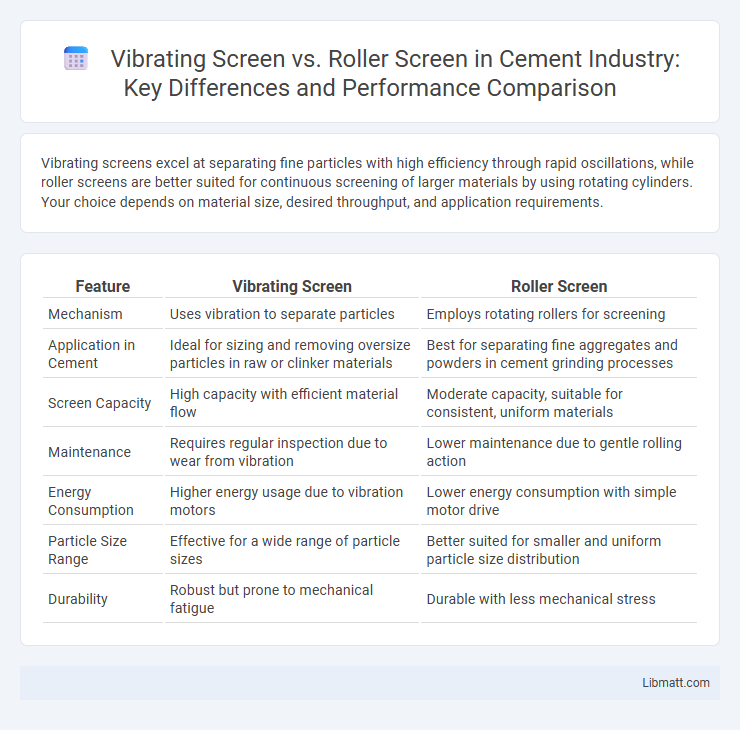

Vibrating screens excel at separating fine particles with high efficiency through rapid oscillations, while roller screens are better suited for continuous screening of larger materials by using rotating cylinders. Your choice depends on material size, desired throughput, and application requirements.

Table of Comparison

| Feature | Vibrating Screen | Roller Screen |

|---|---|---|

| Mechanism | Uses vibration to separate particles | Employs rotating rollers for screening |

| Application in Cement | Ideal for sizing and removing oversize particles in raw or clinker materials | Best for separating fine aggregates and powders in cement grinding processes |

| Screen Capacity | High capacity with efficient material flow | Moderate capacity, suitable for consistent, uniform materials |

| Maintenance | Requires regular inspection due to wear from vibration | Lower maintenance due to gentle rolling action |

| Energy Consumption | Higher energy usage due to vibration motors | Lower energy consumption with simple motor drive |

| Particle Size Range | Effective for a wide range of particle sizes | Better suited for smaller and uniform particle size distribution |

| Durability | Robust but prone to mechanical fatigue | Durable with less mechanical stress |

Introduction to Vibrating Screens and Roller Screens

Vibrating screens use rapid circular or linear motion to separate materials based on particle size, enhancing sorting efficiency in mining and construction industries. Roller screens employ rotating cylinders with tailored gaps to filter and classify bulk materials, ideal for applications requiring gentle handling and continuous operation. Understanding the differences in mechanism and application helps you choose the optimal screening solution tailored to your processing needs.

Working Principles: Vibrating Screen vs Roller Screen

Vibrating screens operate by using mechanical vibrations to separate materials based on particle size, efficiently sorting bulk materials through a mesh or perforated surface. Roller screens separate materials by passing them over rotating cylindrical rollers that filter or sieve particles according to size and shape, often handling coarse materials and sticky substances. The choice between vibrating and roller screens depends on material characteristics and desired screening precision, with vibrating screens excelling in fine particle separation and roller screens offering durability for heavy or abrasive materials.

Design and Structural Differences

Vibrating screens use a motor-driven mechanism to create oscillations that separate materials based on size, while roller screens rely on rotating cylindrical rollers to filter particles. The design of vibrating screens features a flat or inclined deck supported by springs, enabling efficient screening motion, whereas roller screens have sets of rollers arranged in parallel, emphasizing continuous screening with minimal vibration. Your choice depends on the material type and desired throughput, as vibrating screens handle finer particles with higher precision, and roller screens excel in processing coarse or wet materials.

Screening Efficiency Comparison

Vibrating screens offer higher screening efficiency due to their rapid oscillatory motion, which effectively separates finer particles and prevents clogging. Roller screens provide slower, continuous screening suitable for coarser materials but may result in lower separation precision and reduced throughput. Screening efficiency largely depends on particle size distribution and material moisture, with vibrating screens excelling in fine and wet material classification.

Material Handling Capabilities

Vibrating screens excel in handling bulk materials with varying particle sizes, efficiently separating fine and coarse particles through high-frequency vibrations. Roller screens provide precise material grading by using rotating cylinders that gently process fragile or sticky substances without clogging. Both options optimize material throughput but cater to different handling needs based on particle size, moisture content, and material abrasiveness.

Maintenance Requirements and Durability

Vibrating screens require regular inspection of motor mounts, springs, and screen panels to prevent wear and maintain optimal performance, while roller screens demand frequent lubrication and check-ups on rollers and bearings to avoid operational downtime. In terms of durability, vibrating screens are robust against heavy impacts and abrasive materials but may suffer from motor or spring fatigue over time. Roller screens excel in handling sticky or fibrous materials with less risk of clogging and typically exhibit longer service life when maintained with consistent roller and drive system care.

Common Applications and Use Cases

Vibrating screens are widely used in mining, construction, and recycling industries for sorting and separating bulk materials like minerals, aggregates, and waste. Roller screens are ideal for agricultural and food processing applications, effectively sifting grains, seeds, and similar products to remove debris and ensure quality. Selecting the appropriate screen depends on your material type and desired separation efficiency.

Energy Consumption and Cost Implications

Vibrating screens typically consume more energy due to their high-frequency oscillations, which result in increased operational costs over time. Roller screens, with their lower energy requirements and simpler mechanical design, offer a cost-effective alternative by reducing power consumption and maintenance expenses. Choosing the right screening technology for your application can significantly impact both energy efficiency and overall project budget.

Advantages and Disadvantages of Each System

Vibrating screens offer high throughput and efficient separation of materials with variable particle sizes but can suffer from noise and maintenance issues due to mechanical wear. Roller screens provide consistent screening with lower energy consumption and reduced noise, making them ideal for fragile materials, yet they may struggle with fine particle separation and require frequent cleaning. Understanding these trade-offs helps you choose the right screening system for your specific processing needs.

Choosing the Right Screen for Your Operation

Selecting the right screen for your operation depends on material type, grain size, and desired throughput. Vibrating screens excel in handling fine to medium particles with high efficiency in separation and dewatering processes, ideal for mining and aggregate applications. Roller screens are best suited for coarse materials and heavy-duty crushing operations, providing durability and consistent particle sizing in recycling and construction industries.

Vibrating Screen vs Roller Screen Infographic

libmatt.com

libmatt.com