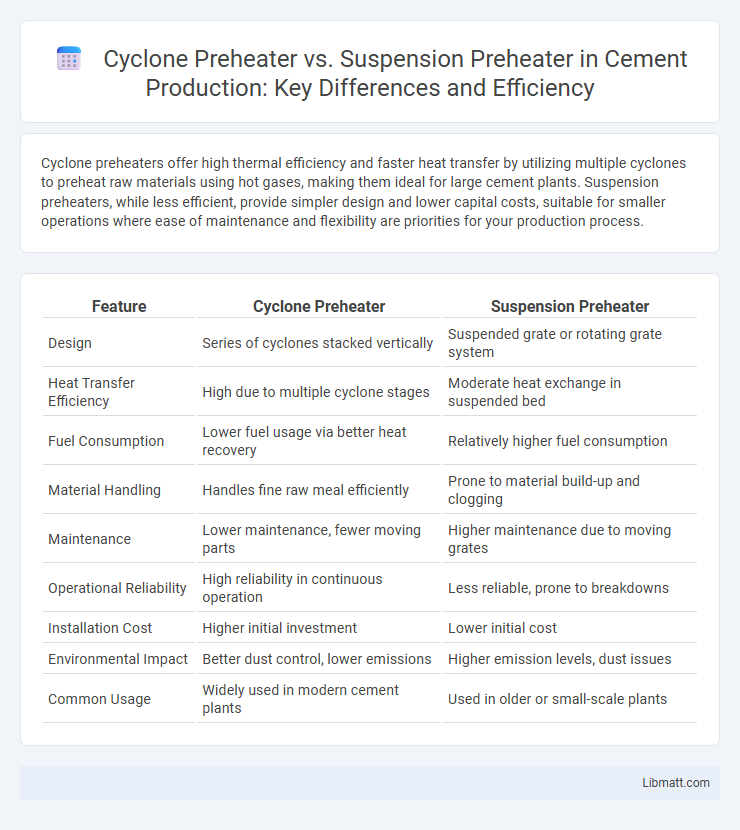

Cyclone preheaters offer high thermal efficiency and faster heat transfer by utilizing multiple cyclones to preheat raw materials using hot gases, making them ideal for large cement plants. Suspension preheaters, while less efficient, provide simpler design and lower capital costs, suitable for smaller operations where ease of maintenance and flexibility are priorities for your production process.

Table of Comparison

| Feature | Cyclone Preheater | Suspension Preheater |

|---|---|---|

| Design | Series of cyclones stacked vertically | Suspended grate or rotating grate system |

| Heat Transfer Efficiency | High due to multiple cyclone stages | Moderate heat exchange in suspended bed |

| Fuel Consumption | Lower fuel usage via better heat recovery | Relatively higher fuel consumption |

| Material Handling | Handles fine raw meal efficiently | Prone to material build-up and clogging |

| Maintenance | Lower maintenance, fewer moving parts | Higher maintenance due to moving grates |

| Operational Reliability | High reliability in continuous operation | Less reliable, prone to breakdowns |

| Installation Cost | Higher initial investment | Lower initial cost |

| Environmental Impact | Better dust control, lower emissions | Higher emission levels, dust issues |

| Common Usage | Widely used in modern cement plants | Used in older or small-scale plants |

Introduction to Preheaters in Industrial Processes

Cyclone preheaters and suspension preheaters are crucial components in cement manufacturing that enhance energy efficiency by preheating raw materials before entering the kiln. Cyclone preheaters utilize multiple cyclones arranged vertically, allowing hot gases to pass through and transfer heat efficiently, while suspension preheaters use a single or multiple-stage system where solid particles are suspended in hot gas streams for heat exchange. Understanding the differences in design and heat transfer mechanisms helps optimize your industrial process for reduced fuel consumption and increased production capacity.

Overview of Cyclone Preheater Technology

Cyclone preheater technology uses a series of cyclones to heat raw meal before it enters the kiln, enhancing thermal efficiency and reducing fuel consumption compared to suspension preheaters. This system improves raw material drying and preheating by utilizing cyclone separators that facilitate better gas-solid contact, leading to uniform heat distribution. Your cement plant's energy savings and processing capacity can significantly increase with the optimized design and operation of cyclone preheaters.

Fundamentals of Suspension Preheater Systems

Suspension preheater systems utilize finely ground raw material particles suspended in hot gas, allowing efficient heat transfer through direct contact. Cyclone preheaters, a common type of suspension preheater, use multiple cyclone stages to separate and recirculate raw meal, increasing thermal efficiency and reducing fuel consumption. Your cement plant can benefit from a suspension preheater system's ability to improve kiln throughput and lower operational costs through enhanced energy recovery.

Key Differences: Cyclone Preheater vs Suspension Preheater

Cyclone preheaters utilize a series of stacked cyclones to efficiently separate and preheat raw meal particles by using hot gas, leading to improved heat exchange and energy savings compared to suspension preheaters, which rely on a simpler vertical riser to suspend and preheat the raw material. The cyclone preheater design enables higher throughput and better dust separation, resulting in enhanced process control and reduced emissions. Your choice between these systems impacts overall kiln efficiency, fuel consumption, and maintenance requirements due to their distinct operational mechanisms.

Energy Efficiency Comparison

Cyclone preheaters demonstrate higher energy efficiency compared to suspension preheaters by utilizing a more effective heat exchange process that recovers heat from exhaust gases to preheat raw materials. The multi-stage design of cyclone preheaters allows for progressive temperature increases, reducing fuel consumption and lowering operational costs. Your choice of preheater significantly impacts overall plant energy efficiency, with cyclone preheaters delivering superior thermal performance and lower emissions.

Impact on Material Quality

Cyclone preheaters offer enhanced material quality by providing uniform heating and rapid calcination, which reduces the risk of overburning and improves clinker homogeneity. Suspension preheaters, while simpler in design, may cause uneven temperature distribution that can lead to variable product properties and inconsistent material strength. Optimizing the preheating process with cyclones results in better control over chemical composition and particle size distribution, directly impacting final product performance.

Space and Installation Requirements

Cyclone preheaters require a relatively compact footprint due to their vertical, multi-stage design, making them ideal for plants with limited space, while suspension preheaters generally need more horizontal space for their single-stage, suspended configuration. Installation of cyclone preheaters is more complex, involving precise alignment and multiple cyclones, which can extend project timelines and costs, whereas suspension preheaters typically offer simpler installation and maintenance due to fewer components. Your choice between these systems should consider available plant space and installation capabilities to optimize operational efficiency and cost-effectiveness.

Maintenance and Operational Considerations

Cyclone preheaters typically require more intensive maintenance due to their complex design and higher operating temperatures, while suspension preheaters offer easier access for routine inspections and cleaning. Operationally, suspension preheaters provide more stable temperature control and reduced dust buildup, enhancing overall plant efficiency and reliability. You should consider the maintenance frequency and operational consistency of each system to optimize your cement production process.

Environmental and Emission Implications

Cyclone preheaters generally generate lower particulate emissions compared to suspension preheaters due to their efficient dust separation and lower operating temperatures, which reduce NOx formation. Suspension preheaters tend to emit higher levels of particulate matter and volatile organic compounds (VOCs) because of incomplete combustion and less effective dust control mechanisms. Implementing advanced filtration and gas treatment systems is essential for both technologies to comply with stringent environmental regulations and minimize their impact on air quality.

Choosing the Right Preheater for Your Plant

Cyclone preheaters offer higher efficiency by utilizing multiple stages to recover heat from kiln exhaust gases, making them ideal for large cement plants aiming to reduce fuel consumption and emissions. Suspension preheaters, while simpler and more cost-effective, provide lower heat exchange efficiency and are better suited for smaller operations with limited capital investment. When choosing the right preheater for your plant, evaluating scale, energy costs, and maintenance capabilities ensures optimal performance and long-term savings.

Cyclone preheater vs Suspension preheater Infographic

libmatt.com

libmatt.com