Limestone Calcined Clay Cement (LC3) offers enhanced sustainability and reduced carbon emissions compared to Ordinary Portland Cement (OPC) by partially replacing clinker with calcined clay and limestone, resulting in lower energy consumption and environmental impact. You can benefit from LC3's improved durability and cost-effectiveness in construction projects aiming for greener alternatives without compromising performance.

Table of Comparison

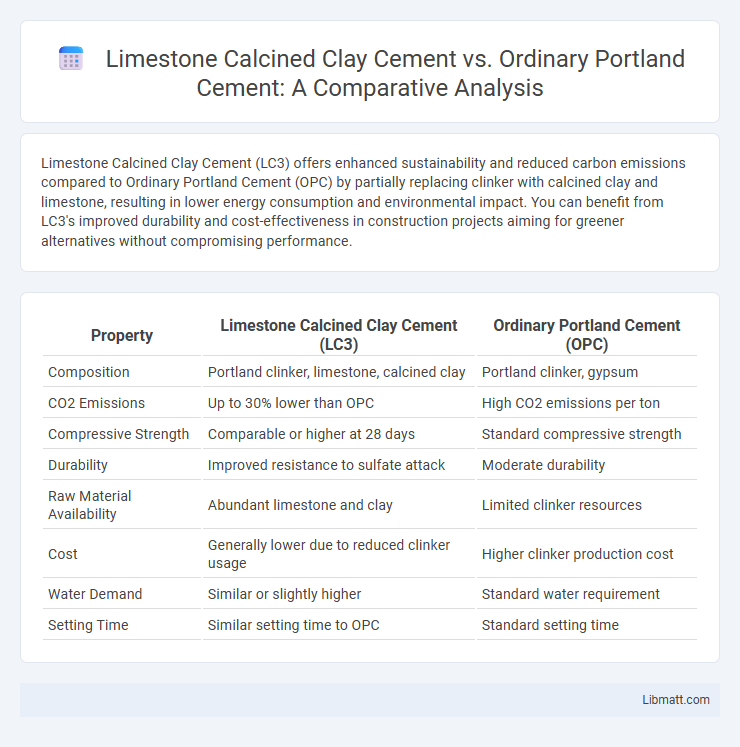

| Property | Limestone Calcined Clay Cement (LC3) | Ordinary Portland Cement (OPC) |

|---|---|---|

| Composition | Portland clinker, limestone, calcined clay | Portland clinker, gypsum |

| CO2 Emissions | Up to 30% lower than OPC | High CO2 emissions per ton |

| Compressive Strength | Comparable or higher at 28 days | Standard compressive strength |

| Durability | Improved resistance to sulfate attack | Moderate durability |

| Raw Material Availability | Abundant limestone and clay | Limited clinker resources |

| Cost | Generally lower due to reduced clinker usage | Higher clinker production cost |

| Water Demand | Similar or slightly higher | Standard water requirement |

| Setting Time | Similar setting time to OPC | Standard setting time |

Introduction to Limestone Calcined Clay Cement and Ordinary Portland Cement

Limestone Calcined Clay Cement (LC3) is an eco-friendly alternative to Ordinary Portland Cement (OPC), combining calcined clay and limestone to reduce carbon emissions while maintaining strength and durability. OPC, a traditional cement type made primarily of clinker, requires higher energy consumption and emits more CO2 during production. LC3 offers enhanced sustainability by optimizing raw material usage and lowering environmental impact compared to conventional OPC.

Composition and Raw Materials

Limestone Calcined Clay Cement (LC3) primarily consists of about 50% clinker, 30% calcined clay, 15% limestone, and 5% gypsum, using abundant materials like kaolinite-rich clay and high-purity limestone. Ordinary Portland Cement (OPC) is mainly composed of 95% clinker and 5% gypsum, relying heavily on limestone, clay, and minor amounts of silica and alumina. The inclusion of calcined clay and higher limestone content in LC3 reduces clinker demand, lowering CO2 emissions while maintaining comparable performance to traditional OPC.

Manufacturing Processes

Limestone Calcined Clay Cement (LC3) manufacturing involves blending clinker with calcined clay and limestone, reducing clinker content by up to 50%, which lowers CO2 emissions compared to Ordinary Portland Cement (OPC). OPC production requires high-temperature clinkerization of limestone and other raw materials, resulting in higher energy consumption and carbon footprint. Incorporating calcined clay in LC3 enhances pozzolanic activity, improving sustainability through reduced resource depletion and emissions during manufacturing.

Environmental Impact and Sustainability

Limestone Calcined Clay Cement (LC3) significantly reduces CO2 emissions by replacing a substantial portion of clinker with calcined clay and limestone, lowering the carbon footprint compared to Ordinary Portland Cement (OPC). LC3's production consumes less energy due to lower kiln temperatures, contributing to enhanced environmental sustainability. This cement type also promotes resource efficiency by utilizing abundant clay and limestone materials, reducing reliance on scarce and energy-intensive clinker manufacturing.

Mechanical and Durability Performance

Limestone Calcined Clay Cement (LC3) exhibits enhanced mechanical performance with higher early strength and comparable long-term strength to Ordinary Portland Cement (OPC). LC3 also demonstrates superior durability due to improved resistance to chloride ion penetration, sulfate attack, and reduced permeability, which prolongs structural lifespan. Your construction projects benefit from LC3's eco-friendly profile without compromising on strength or durability.

Cost Analysis and Economic Viability

Limestone Calcined Clay Cement (LC3) offers a significant cost advantage over Ordinary Portland Cement (OPC) due to lower raw material expenses and reduced energy consumption in production, making it economically viable for large-scale construction projects. LC3's use of abundant and inexpensive clays alongside limestone decreases reliance on costly clinker, thus lowering overall manufacturing costs and carbon footprints. Your investment in LC3 can lead to substantial savings while supporting sustainable development goals through cost-effective and eco-friendly building materials.

Carbon Footprint Comparison

Limestone Calcined Clay Cement (LC3) significantly reduces carbon emissions compared to Ordinary Portland Cement (OPC) by utilizing lower clinker content and incorporating abundant calcined clay and limestone. The production of LC3 can cut CO2 emissions by up to 30%, making it a sustainable choice for eco-conscious construction projects. Your choice of LC3 over OPC directly contributes to lowering the building sector's overall carbon footprint.

Applications in Construction

Limestone Calcined Clay Cement (LC3) offers enhanced durability and reduced carbon footprint, making it ideal for sustainable construction projects such as residential buildings, infrastructure works, and precast concrete elements. Ordinary Portland Cement (OPC), widely used in traditional construction, excels in applications requiring high early strength like bridges, highways, and structural concrete. LC3's improved resistance to chemical attacks and lower heat of hydration make it suitable for marine and mass concrete structures where OPC may face durability challenges.

Challenges and Limitations

Limestone Calcined Clay Cement (LC3) faces challenges such as variability in clay quality and the need for optimized calcination processes to achieve consistent performance. Ordinary Portland Cement (OPC) is limited by high carbon emissions and energy consumption during production, but benefits from established supply chains and standardization. You may encounter compatibility issues when substituting LC3 for OPC in existing concrete mixes, requiring thorough testing to ensure durability and strength criteria are met.

Future Prospects and Innovations

Limestone Calcined Clay Cement (LC3) offers promising future prospects by significantly reducing CO2 emissions compared to Ordinary Portland Cement (OPC), aligning with global sustainability goals. Innovations in LC3 production include optimizing calcination processes and integrating alternative clinker replacements to enhance durability and mechanical properties. The expanding adoption of LC3 supports circular economy models and regulatory incentives promoting low-carbon construction materials worldwide.

Limestone Calcined Clay Cement vs Ordinary Portland Cement Infographic

libmatt.com

libmatt.com