Dry mortar plants produce dry mix components that are transported and mixed with water on-site, offering flexibility and reduced transportation costs, while wet mix plants deliver fully mixed concrete ready for immediate use, ensuring consistent quality and faster application. Your choice depends on project requirements, with dry plants suited for small-scale or remote jobs and wet mix plants ideal for large-scale construction needing uniform concrete.

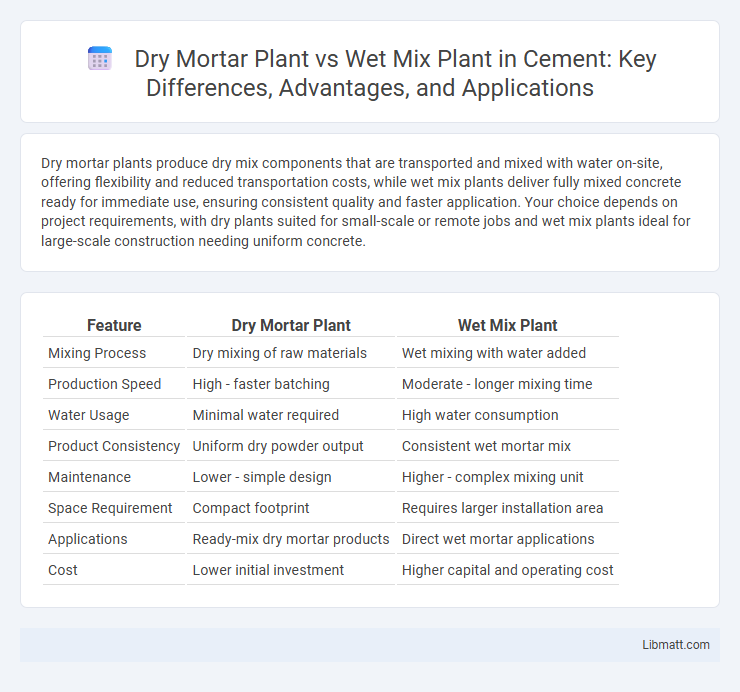

Table of Comparison

| Feature | Dry Mortar Plant | Wet Mix Plant |

|---|---|---|

| Mixing Process | Dry mixing of raw materials | Wet mixing with water added |

| Production Speed | High - faster batching | Moderate - longer mixing time |

| Water Usage | Minimal water required | High water consumption |

| Product Consistency | Uniform dry powder output | Consistent wet mortar mix |

| Maintenance | Lower - simple design | Higher - complex mixing unit |

| Space Requirement | Compact footprint | Requires larger installation area |

| Applications | Ready-mix dry mortar products | Direct wet mortar applications |

| Cost | Lower initial investment | Higher capital and operating cost |

Introduction to Dry Mortar Plant and Wet Mix Plant

Dry mortar plants produce dry powder mixtures that are later mixed with water on-site, ensuring precise control over material consistency and composition. Wet mix plants combine all raw materials with water prior to delivery, offering a ready-to-use concrete solution that enhances work efficiency and consistency. Choosing between these plants depends on Your project's specific requirements regarding timing, transport, and mixing convenience.

Key Components and Technology

Dry mortar plants consist primarily of raw material storage bins, weighers, mixers, and packaging machines, utilizing automated batching systems to ensure precise ingredient ratios. Wet mix plants incorporate additional components such as water supply systems and mixing tanks designed to produce homogenous, high-quality wet mortar with consistent hydration levels. Understanding the key technological differences in material handling and mixing processes helps you choose the right plant based on project requirements and efficiency goals.

Production Process Comparison

Dry mortar plants utilize a dry mix production process where raw materials like sand, cement, and additives are pre-mixed in precise proportions and then packaged or transported for later water addition on-site. Wet mix plants combine raw materials with water during production, producing a ready-to-use mortar with consistent moisture content and reduced mixing time at the construction site. The dry process offers flexibility in water control and easier storage, while the wet process enhances homogeneity and immediacy of application.

Material Handling and Storage

Dry mortar plants utilize separate storage silos and conveyors for dry materials, ensuring precise measurement and minimal moisture exposure, which enhances batch consistency and reduces contamination risk. Wet mix plants handle pre-mixed, wet concrete with integrated agitators and pump systems, requiring robust storage tanks to maintain the material's fluidity and prevent segregation during transport. Efficient material handling in dry mortar plants promotes reduced energy consumption and easier maintenance, whereas wet mix plants demand careful monitoring to avoid setting issues and ensure environmental compliance.

Installation and Setup Requirements

Dry mortar plants require simpler installation with minimal infrastructure, as they handle dry powder mixing on-site, reducing the need for extensive water supply and drainage systems. Wet mix plants demand more complex setup, involving water pumps, pipelines, and curing systems to manage the liquid mortar, increasing time and labor costs for installation. The compact and modular design of dry mortar plants allows for faster deployment and easier relocation compared to the fixed, heavier infrastructure of wet mix plants.

Output Quality and Consistency

Dry mortar plants produce a consistent, high-quality mix by precisely controlling the raw material proportions before water is added at the construction site, ensuring uniformity in output. Wet mix plants blend all ingredients, including water, in a central mixer, resulting in a more homogeneous and superior-quality mortar with fewer air pockets and better strength. Your choice depends on project requirements, with wet mix plants offering enhanced consistency and durability for demanding construction tasks.

Environmental Impact and Waste Management

Dry mortar plants generate less wastewater compared to wet mix plants, reducing risks of water pollution and simplifying waste management protocols. Wet mix plants produce slurry and wastewater requiring specialized treatment systems to prevent soil and water contamination. Efficient dust collection systems in dry mortar plants contribute to lower airborne pollutants, supporting better environmental compliance and sustainability.

Cost Analysis: Initial Investment and Operating Costs

Dry mortar plants typically require a lower initial investment due to simpler machinery and infrastructure compared to wet mix plants, which involve more complex mixing systems and water supply arrangements. Operating costs for dry mortar plants are generally lower, as they consume less energy and have reduced water usage, whereas wet mix plants incur higher expenses from water handling, waste management, and maintenance of mixers. The cost-effectiveness of choosing between dry mortar and wet mix plants depends on project scale, available resources, and long-term production demands.

Application Suitability and Flexibility

Dry mortar plants are ideal for producing various pre-mixed dry mortars used in plastering, masonry, and tile adhesives, offering greater flexibility for small to medium construction projects with variable output demands. Wet mix plants suit large-scale infrastructure and precast concrete production due to their ability to produce consistent, high-quality concrete mixtures with precise water-cement ratios. Application suitability hinges on project scale and consistency requirements, with dry mortar plants providing adaptability in material composition and wet mix plants excelling in efficiency and uniformity for extensive, continuous operations.

Choosing the Right Plant for Your Project

Selecting between a dry mortar plant and a wet mix plant depends on your project's specific requirements, such as production volume, consistency needs, and site conditions. Dry mortar plants offer flexibility and easier storage of materials, while wet mix plants provide superior mixing quality for concrete applications demanding higher uniformity. Understanding the trade-offs will help you optimize your project's efficiency and material performance.

Dry Mortar Plant vs Wet Mix Plant Infographic

libmatt.com

libmatt.com