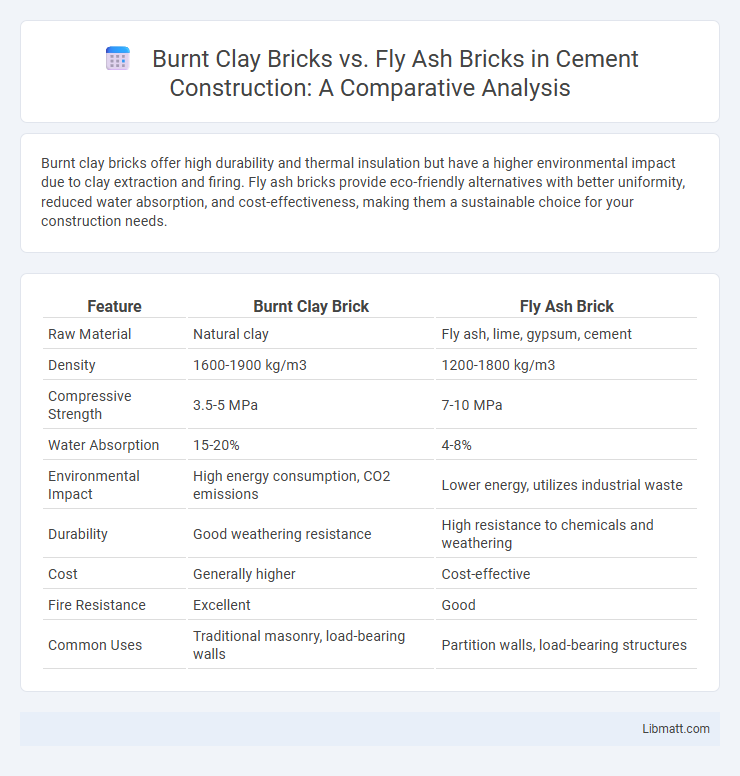

Burnt clay bricks offer high durability and thermal insulation but have a higher environmental impact due to clay extraction and firing. Fly ash bricks provide eco-friendly alternatives with better uniformity, reduced water absorption, and cost-effectiveness, making them a sustainable choice for your construction needs.

Table of Comparison

| Feature | Burnt Clay Brick | Fly Ash Brick |

|---|---|---|

| Raw Material | Natural clay | Fly ash, lime, gypsum, cement |

| Density | 1600-1900 kg/m3 | 1200-1800 kg/m3 |

| Compressive Strength | 3.5-5 MPa | 7-10 MPa |

| Water Absorption | 15-20% | 4-8% |

| Environmental Impact | High energy consumption, CO2 emissions | Lower energy, utilizes industrial waste |

| Durability | Good weathering resistance | High resistance to chemicals and weathering |

| Cost | Generally higher | Cost-effective |

| Fire Resistance | Excellent | Good |

| Common Uses | Traditional masonry, load-bearing walls | Partition walls, load-bearing structures |

Introduction to Burnt Clay Bricks and Fly Ash Bricks

Burnt clay bricks are traditional construction materials made by molding natural clay and firing it at high temperatures, offering durability and thermal insulation. Fly ash bricks are eco-friendly alternatives produced from fly ash, lime, and gypsum, known for their lightweight structure and resistance to moisture. Your choice between the two depends on sustainability goals, strength requirements, and environmental impact.

Raw Materials and Manufacturing Processes

Burnt clay bricks are made from natural clay that is molded and fired in kilns at high temperatures, creating a dense and durable product through thermal hardening. Fly ash bricks utilize fly ash, a byproduct of coal combustion, mixed with lime, cement, and water, then molded and cured under controlled conditions without firing, resulting in lightweight and eco-friendly bricks. The manufacturing of burnt clay bricks involves extensive energy consumption due to kiln firing, whereas fly ash bricks require less energy, promoting sustainability and waste utilization in construction.

Physical and Mechanical Properties Comparison

Burnt clay bricks exhibit higher compressive strength, typically ranging from 10 to 50 MPa, and possess excellent durability and water resistance due to their dense microstructure. Fly ash bricks offer lower density, enhanced thermal insulation, and comparable compressive strength within 7 to 35 MPa, benefiting from improved dimensional stability and reduced efflorescence. Both materials differ in porosity and moisture absorption, with burnt clay bricks having lower porosity than fly ash bricks, influencing their mechanical resilience and long-term performance in construction.

Environmental Impact and Sustainability

Burnt clay bricks require significant energy consumption involving coal or firewood, leading to high carbon emissions and deforestation, which negatively impact the environment. Fly ash bricks utilize industrial waste materials such as fly ash from thermal power plants, reducing landfill waste and lowering carbon footprints due to less energy-intensive manufacturing processes. Sustainable construction practices increasingly favor fly ash bricks for their eco-friendly nature, improved durability, and reduced depletion of natural clay resources.

Cost Analysis and Economic Considerations

Burnt clay bricks typically incur higher production costs due to energy-intensive firing processes and raw material extraction, impacting overall construction budgets. Fly ash bricks offer a cost-effective alternative by utilizing industrial waste and reducing energy consumption, resulting in lower manufacturing expenses and potential savings for builders. Economic considerations favor fly ash bricks for sustainable projects seeking reduced material costs and environmental benefits without compromising structural integrity.

Strength and Durability Performance

Burnt clay bricks exhibit high compressive strength typically ranging from 10 MPa to 20 MPa, providing excellent load-bearing capacity and long-term durability in construction. Fly ash bricks offer comparable strength levels, often between 7 MPa and 15 MPa, with enhanced durability due to lower water absorption and resistance to weathering and chemical attacks. Both types ensure robust structural integrity, but fly ash bricks provide superior environmental benefits and consistent quality through controlled manufacturing processes.

Thermal and Acoustic Insulation Characteristics

Fly ash bricks offer superior thermal insulation compared to burnt clay bricks due to their lower thermal conductivity, helping maintain indoor temperature more effectively and reducing energy consumption. Acoustic insulation is enhanced in fly ash bricks as their denser, uniform structure better absorbs sound waves, resulting in quieter interiors. Choosing fly ash bricks can improve your building's energy efficiency and soundproofing, providing greater comfort in both residential and commercial spaces.

Suitability for Different Construction Applications

Burnt clay bricks are ideal for load-bearing walls and heavy structural elements due to their high compressive strength and thermal insulation properties. Fly ash bricks suit non-load-bearing partitions and eco-friendly construction projects because of their lighter weight, consistent size, and lower water absorption rates. Both types offer distinct benefits, with burnt clay bricks favored for traditional masonry and fly ash bricks preferred in sustainable building designs.

Maintenance and Lifespan

Burnt clay bricks typically require minimal maintenance due to their inherent durability and natural resistance to weathering, offering a lifespan of over 50 years in most construction settings. Fly ash bricks provide excellent resistance to moisture and pests, reducing long-term maintenance costs, and can last up to 35-40 years with proper care. Your choice between these bricks should consider the specific environmental conditions and maintenance capabilities to maximize structural longevity.

Conclusion: Which Brick is Better for Modern Construction?

Fly ash bricks are better suited for modern construction due to their superior environmental benefits, including lower carbon emissions and reduced use of natural clay, which conserves topsoil. These bricks offer enhanced strength, durability, and uniformity compared to traditional burnt clay bricks, contributing to higher structural integrity and energy efficiency in buildings. Cost-effective production, lightweight properties, and better thermal insulation make fly ash bricks a sustainable and practical choice for contemporary construction projects.

Burnt clay brick vs Fly ash brick Infographic

libmatt.com

libmatt.com