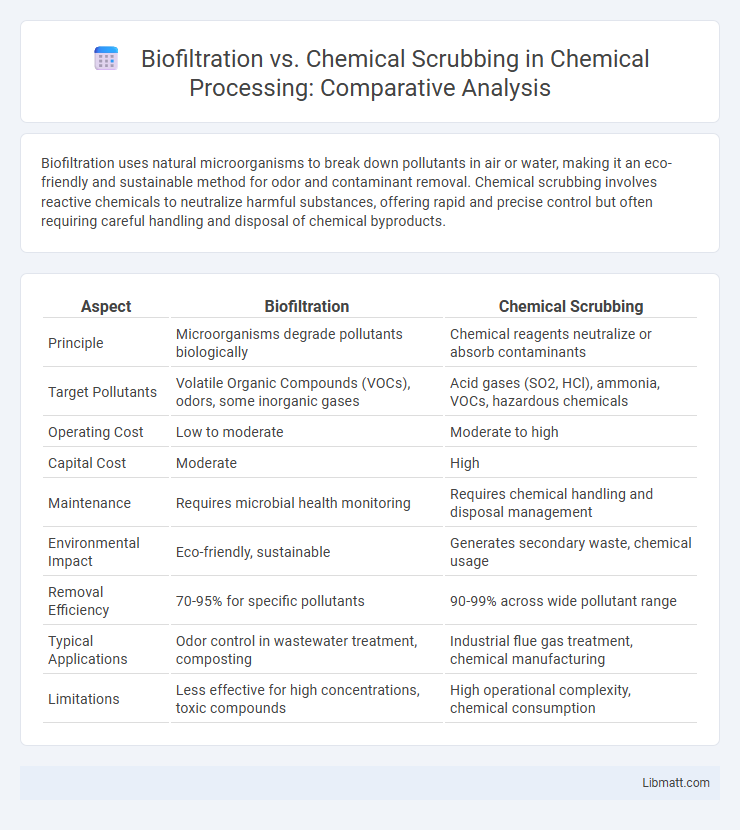

Biofiltration uses natural microorganisms to break down pollutants in air or water, making it an eco-friendly and sustainable method for odor and contaminant removal. Chemical scrubbing involves reactive chemicals to neutralize harmful substances, offering rapid and precise control but often requiring careful handling and disposal of chemical byproducts.

Table of Comparison

| Aspect | Biofiltration | Chemical Scrubbing |

|---|---|---|

| Principle | Microorganisms degrade pollutants biologically | Chemical reagents neutralize or absorb contaminants |

| Target Pollutants | Volatile Organic Compounds (VOCs), odors, some inorganic gases | Acid gases (SO2, HCl), ammonia, VOCs, hazardous chemicals |

| Operating Cost | Low to moderate | Moderate to high |

| Capital Cost | Moderate | High |

| Maintenance | Requires microbial health monitoring | Requires chemical handling and disposal management |

| Environmental Impact | Eco-friendly, sustainable | Generates secondary waste, chemical usage |

| Removal Efficiency | 70-95% for specific pollutants | 90-99% across wide pollutant range |

| Typical Applications | Odor control in wastewater treatment, composting | Industrial flue gas treatment, chemical manufacturing |

| Limitations | Less effective for high concentrations, toxic compounds | High operational complexity, chemical consumption |

Introduction to Air Pollution Control Technologies

Biofiltration and chemical scrubbing are essential air pollution control technologies designed to remove contaminants from industrial emissions. Biofiltration leverages microorganisms to biologically degrade volatile organic compounds (VOCs) and odors, making it energy-efficient and environmentally friendly. Chemical scrubbing uses reactive chemicals to neutralize pollutants such as sulfur dioxide and acidic gases, offering rapid, reliable removal but often requiring higher operational costs and maintenance.

What is Biofiltration?

Biofiltration is an environmentally friendly air pollution control technology that uses living microorganisms to degrade and remove organic compounds and odors from contaminated air streams. This natural process relies on biofilms formed on a porous medium where microbes metabolize pollutants into harmless byproducts such as carbon dioxide and water. Compared to chemical scrubbing, biofiltration operates at lower costs and avoids hazardous chemicals, making it ideal for treating volatile organic compounds (VOCs) in industrial emissions.

Understanding Chemical Scrubbing

Chemical scrubbing employs liquid absorbents, often alkaline solutions, to remove pollutants such as sulfur dioxide or ammonia from industrial gas emissions. This method enables precise control over contaminant removal and is effective for high-concentration, non-biological pollutants. Understanding chemical scrubbing helps you choose a technology that offers rapid treatment and predictable results compared to the biological processes used in biofiltration.

Key Differences Between Biofiltration and Chemical Scrubbing

Biofiltration uses microorganisms to naturally degrade pollutants in air or water, making it an eco-friendly and cost-effective option for removing organic compounds and odors. Chemical scrubbing involves chemical reactions, often using liquid solutions like alkaline or acidic absorbents, to neutralize or remove contaminants such as sulfur dioxide or ammonia. Your choice between biofiltration and chemical scrubbing depends on factors like pollutant type, treatment efficiency, operational costs, and environmental impact.

Efficiency and Effectiveness Comparison

Biofiltration offers high efficiency in removing biodegradable volatile organic compounds (VOCs) and odors, achieving removal rates of 70-95% under optimal conditions. Chemical scrubbing excels in handling a broader range of pollutants, including acidic gases like SO2 and H2S, with removal efficiencies often exceeding 90%. The effectiveness of biofiltration depends on microbial activity and environmental factors, while chemical scrubbers provide rapid, consistent pollutant removal but require higher operational costs and chemical inputs.

Environmental Impact Assessment

Biofiltration offers a lower environmental impact compared to chemical scrubbing by utilizing natural microbial processes to degrade pollutants, reducing hazardous waste generation and chemical usage. Chemical scrubbing often involves the use of corrosive substances and produces secondary pollutants that require careful disposal to prevent soil and water contamination. Your choice between these air pollution control methods should consider the sustainability of biofiltration and the potential environmental risks associated with chemical scrubbing.

Cost Analysis: Biofiltration vs Chemical Scrubbing

Biofiltration typically incurs lower operational costs compared to chemical scrubbing due to its reliance on naturally occurring microorganisms and minimal energy input. Chemical scrubbing demands higher expenses for chemical reagents, waste disposal, and maintenance of complex equipment. Your choice should consider long-term cost efficiency, with biofiltration offering a more sustainable and economically viable solution for many industrial applications.

Maintenance and Operational Considerations

Biofiltration systems require lower maintenance due to their natural microbial processes, needing periodic media replacement and moisture control, while chemical scrubbing demands frequent monitoring and replenishment of chemical reagents to maintain efficiency. Operational considerations for biofiltration include managing airflow rates and temperature to optimize microbial activity, whereas chemical scrubbers require handling corrosive substances and ensuring proper waste disposal. Biofiltration generally offers lower operational costs and environmental impact, contrasting with chemical scrubbing's higher energy consumption and potential chemical hazards.

Suitable Applications for Each Method

Biofiltration is ideal for treating low to moderate concentrations of biodegradable volatile organic compounds (VOCs) and odors in wastewater and air streams from industries like food processing and pharmaceuticals. Chemical scrubbing excels in handling high concentrations of acidic gases, such as sulfur dioxide and hydrogen sulfide, commonly found in petrochemical and mining operations. Your choice depends on the specific pollutants and concentration levels, with biofiltration favored for sustainable, low-impact environments and chemical scrubbing suited for aggressive, high-strength emissions.

Future Trends in Air Pollutant Removal Technologies

Future trends in air pollutant removal technologies emphasize enhanced biofiltration systems using genetically engineered microorganisms to target specific volatile organic compounds and improve degradation rates. Chemical scrubbing advancements focus on eco-friendly solvents and hybrid systems combining scrubbing with catalytic oxidation to increase efficiency and reduce secondary waste. Integration of real-time monitoring and AI controls enables adaptive optimization, making both biofiltration and chemical scrubbing more sustainable and cost-effective for industrial applications.

biofiltration vs chemical scrubbing Infographic

libmatt.com

libmatt.com