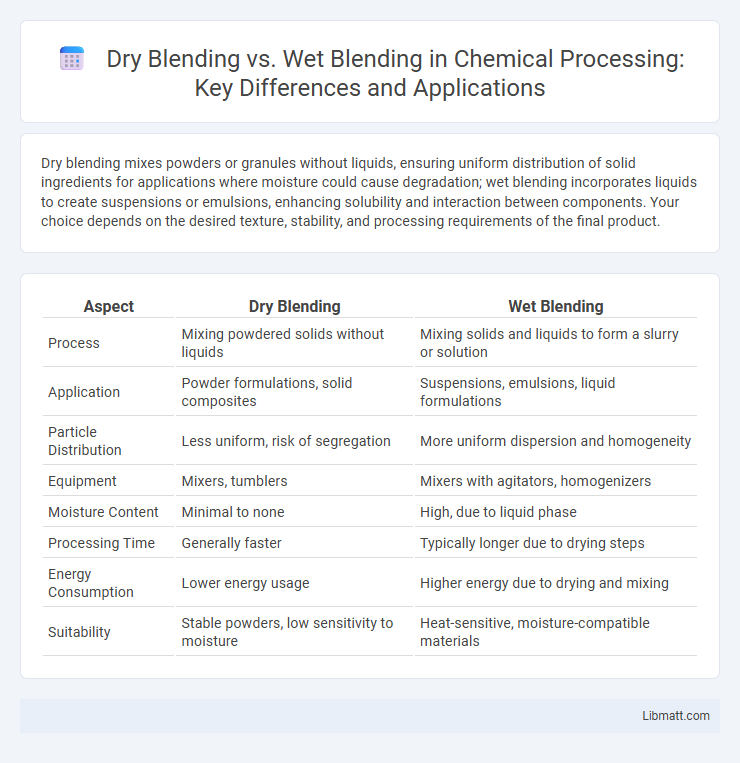

Dry blending mixes powders or granules without liquids, ensuring uniform distribution of solid ingredients for applications where moisture could cause degradation; wet blending incorporates liquids to create suspensions or emulsions, enhancing solubility and interaction between components. Your choice depends on the desired texture, stability, and processing requirements of the final product.

Table of Comparison

| Aspect | Dry Blending | Wet Blending |

|---|---|---|

| Process | Mixing powdered solids without liquids | Mixing solids and liquids to form a slurry or solution |

| Application | Powder formulations, solid composites | Suspensions, emulsions, liquid formulations |

| Particle Distribution | Less uniform, risk of segregation | More uniform dispersion and homogeneity |

| Equipment | Mixers, tumblers | Mixers with agitators, homogenizers |

| Moisture Content | Minimal to none | High, due to liquid phase |

| Processing Time | Generally faster | Typically longer due to drying steps |

| Energy Consumption | Lower energy usage | Higher energy due to drying and mixing |

| Suitability | Stable powders, low sensitivity to moisture | Heat-sensitive, moisture-compatible materials |

Introduction to Dry Blending and Wet Blending

Dry blending involves mixing solid materials such as powders, granules, or pellets without the use of liquids, ensuring uniform distribution of components while maintaining low moisture content. Wet blending combines solid ingredients with liquids to facilitate better dispersion, improve homogeneity, and enhance the interaction between components, often used in pharmaceutical, food, and chemical industries. Choosing between dry and wet blending depends on factors like material properties, desired product consistency, and processing requirements.

Key Differences Between Dry and Wet Blending

Dry blending involves mixing powder or solid ingredients without any liquid, preserving the original texture and preventing reactions. Wet blending combines ingredients with liquids, enhancing uniformity and solubility but requiring careful control to avoid separation or clumping. Your choice depends on the desired product consistency, processing conditions, and final application requirements.

Advantages of Dry Blending

Dry blending offers precise control over ingredient proportions, ensuring consistent product quality in industries like pharmaceuticals and food processing. It reduces processing time and energy consumption by eliminating the need for additional drying steps associated with wet blending. This method also minimizes the risk of contamination and degradation of moisture-sensitive materials, enhancing overall product stability and shelf life.

Advantages of Wet Blending

Wet blending offers superior homogeneity by thoroughly mixing powders and liquids, which enhances product consistency and quality. It reduces dust generation and improves safety during handling, minimizing airborne contaminants in manufacturing environments. The process also allows better control over particle size distribution and dispersion, resulting in improved texture and performance in final products.

Applications Suited for Dry Blending

Dry blending is ideally suited for applications requiring uniform distribution of powders without moisture addition, such as in the production of pharmaceuticals, powdered food products, and chemical compounds. This method ensures precise control over particle size and consistency, making it essential for formulations sensitive to moisture or requiring high flowability. Industries that benefit from dry blending include detergent manufacturing, metal powder processing, and cosmetic production, where dry ingredient homogeneity is critical.

Applications Suited for Wet Blending

Wet blending is ideally suited for applications requiring uniform dispersion of liquids, powders, or granules in industries such as pharmaceuticals, cosmetics, and food processing. This method excels in producing stable emulsions, suspensions, and homogenous mixtures necessary for creams, sauces, and liquid medications. Wet blending enhances solubility and texture, making it essential for high-viscosity formulations and products with sensitive ingredients.

Equipment and Technology Used

Dry blending uses equipment such as ribbon blenders, V-blenders, and cone mixers designed to mix powders without added liquids, relying on tumbling or rotating motion for uniformity. Wet blending employs high-shear mixers, agitators, and homogenizers to effectively combine powders with liquids, ensuring even dispersion and improved consistency in suspensions or emulsions. Advanced technologies in wet blending also include ultrasonicators and high-pressure homogenizers that enhance particle size reduction and mixture stability.

Cost and Efficiency Comparison

Dry blending typically incurs lower costs due to reduced energy consumption and simpler processing equipment, making it more efficient for large-scale production with less moisture-sensitive materials. Wet blending often requires higher operational expenses, including energy for drying and specialized equipment to manage liquid components, but can enhance uniformity and product quality in applications needing precise ingredient distribution. Efficiency in dry blending excels with faster batch cycles and minimal cleanup, while wet blending benefits processes demanding thorough integration of powders with liquids despite longer processing times.

Quality Control Considerations

Dry blending offers greater consistency in particle size distribution, reducing the risk of moisture-related clumping, which simplifies quality control protocols. Wet blending allows for better dispersion of ingredients and can improve homogeneity, but requires stringent monitoring of moisture content and drying conditions to prevent microbial growth or product degradation. Your choice between dry and wet blending should consider the specific quality control challenges associated with each method to ensure optimal product reliability.

Choosing the Right Blending Method for Your Needs

Dry blending involves mixing powders or granules without moisture, ideal for applications needing uniform particle distribution and preservation of ingredient integrity, while wet blending uses liquids to create homogeneous mixtures, suitable for formulations requiring dissolution or enhanced binding. Selecting the appropriate blending method depends on factors such as ingredient properties, desired texture, processing equipment, and end-product stability. Understanding the physical characteristics and intended use of the components ensures optimal mixing efficiency and product quality.

dry blending vs wet blending Infographic

libmatt.com

libmatt.com