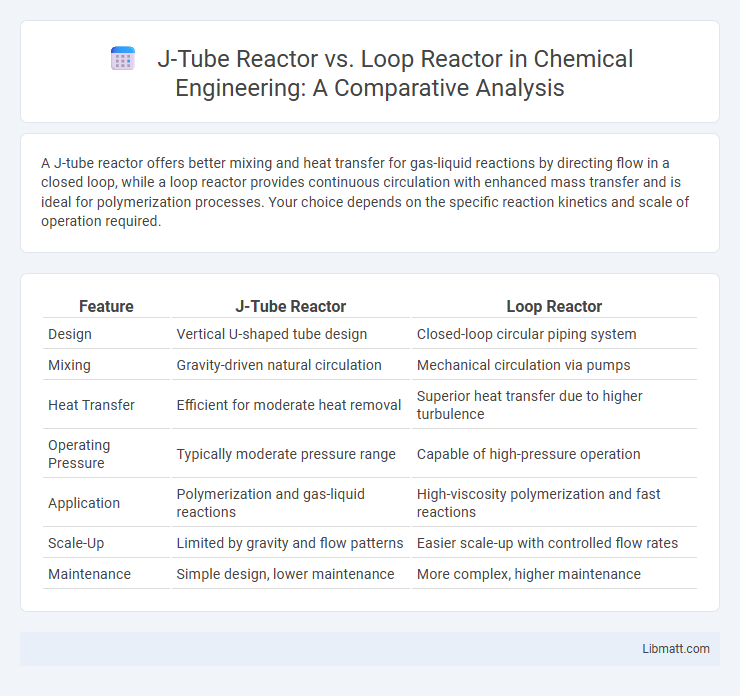

A J-tube reactor offers better mixing and heat transfer for gas-liquid reactions by directing flow in a closed loop, while a loop reactor provides continuous circulation with enhanced mass transfer and is ideal for polymerization processes. Your choice depends on the specific reaction kinetics and scale of operation required.

Table of Comparison

| Feature | J-Tube Reactor | Loop Reactor |

|---|---|---|

| Design | Vertical U-shaped tube design | Closed-loop circular piping system |

| Mixing | Gravity-driven natural circulation | Mechanical circulation via pumps |

| Heat Transfer | Efficient for moderate heat removal | Superior heat transfer due to higher turbulence |

| Operating Pressure | Typically moderate pressure range | Capable of high-pressure operation |

| Application | Polymerization and gas-liquid reactions | High-viscosity polymerization and fast reactions |

| Scale-Up | Limited by gravity and flow patterns | Easier scale-up with controlled flow rates |

| Maintenance | Simple design, lower maintenance | More complex, higher maintenance |

Overview of J-Tube and Loop Reactors

J-tube reactors feature a vertical, U-shaped tube facilitating continuous catalyst circulation and precise temperature control, ideal for polymerization processes. Loop reactors consist of a circulating loop with a pump, providing high mixing efficiency and superior heat transfer for large-scale production. The choice between J-tube and loop reactors depends on factors like scale, reaction kinetics, and desired polymer properties.

Design Principles of J-Tube Reactors

J-tube reactors are designed with a vertical, U-shaped structure that facilitates efficient gas-liquid contact, enhancing mass transfer and mixing in multiphase catalytic reactions. Their design optimizes residence time distribution by promoting plug flow behavior, minimizing back-mixing and ensuring better reaction control compared to loop reactors. Unlike loop reactors, which utilize circulating liquid flow to improve mixing, J-tube reactors rely on gravity and gas evolution to maintain phase dispersion and steady operational stability.

Structural Features of Loop Reactors

Loop reactors feature a circular or oval flow path, promoting continuous circulation of reactants through external pumps or gas lift, which enhances mixing and heat transfer efficiency compared to the linear flow in J-tube reactors. Their structural design minimizes pressure drops and allows for higher operational volumes and better control of temperature gradients, essential for exothermic reactions. Your choice of loop reactors supports improved scalability and process safety in large-scale chemical production.

Mixing and Flow Dynamics Comparison

J-tube reactors provide plug flow with limited back-mixing, ensuring uniform residence time and enhanced conversion efficiency for reactions requiring precise control. Loop reactors exhibit vigorous mixing and turbulence, promoting excellent heat and mass transfer, ideal for highly exothermic or fast reactions. Your selection depends on whether controlled flow or intense mixing optimizes your reaction performance.

Mass and Heat Transfer Efficiency

J-tube reactors provide enhanced heat transfer efficiency due to their vertical design, which facilitates natural circulation and uniform temperature distribution. Loop reactors excel in mass transfer efficiency by promoting continuous mixing and high turbulence, improving gas-liquid interactions. Your choice depends on whether superior heat management or mass transfer performance is more critical for your process.

Operational Advantages and Limitations

J-tube reactors offer precise temperature control and uniform flow distribution, enhancing reaction efficiency in polymerization processes, whereas loop reactors provide higher solids handling capacity and better mixing due to continuous recirculation. J-tube reactors face limitations in scale-up and pressure drop management, while loop reactors encounter challenges with fouling and complex control systems. Choosing between these reactor types depends on specific process requirements such as polymer type, production scale, and operational flexibility.

Industrial Applications of Both Reactor Types

J-tube reactors are extensively used in petrochemical industries for catalytic reforming and hydrogenation due to their efficient heat transfer and ease of catalyst loading. Loop reactors find significant application in the polymerization industry, particularly for producing polyethylene and polypropylene, owing to their superior mixing and temperature control. Both reactor types serve vital roles in chemical manufacturing processes, optimizing reaction rates and product quality.

Scalability and Flexibility Considerations

J-tube reactors offer compact scalability with ease in scaling-out through parallel units, making them suitable for small to medium production volumes; loop reactors provide superior scalability for large-scale operations due to their continuous, high-throughput design. Flexibility favors J-tube reactors as they allow rapid adjustments in reaction conditions and accommodate various feedstocks, while loop reactors excel in processes requiring consistent mixing and residence times but have limited operational adaptability. Your choice depends on desired production scale and the need for process flexibility versus high-capacity continuous operation.

Energy Consumption and Cost Analysis

J-tube reactors typically exhibit lower energy consumption due to their compact design and efficient heat transfer rates, which reduce operational costs compared to loop reactors. Loop reactors require higher pumping power to maintain circulation, increasing energy usage and maintenance expenses. Cost analysis shows that while J-tube reactors have higher initial capital investment, their reduced energy and maintenance costs result in lower total cost of ownership over time.

Selecting the Ideal Reactor for Specific Processes

J-tube reactors offer enhanced gas-liquid contact ideal for catalytic cracking and polymerization processes requiring precise temperature control and efficient phase mixing. Loop reactors provide superior fluid dynamics and homogeneity, making them suitable for large-scale slurry-phase reactions and high-viscosity polymer synthesis. Selecting between J-tube and loop reactors depends on process parameters such as reaction kinetics, heat transfer needs, and feedstock characteristics.

J-tube reactor vs loop reactor Infographic

libmatt.com

libmatt.com