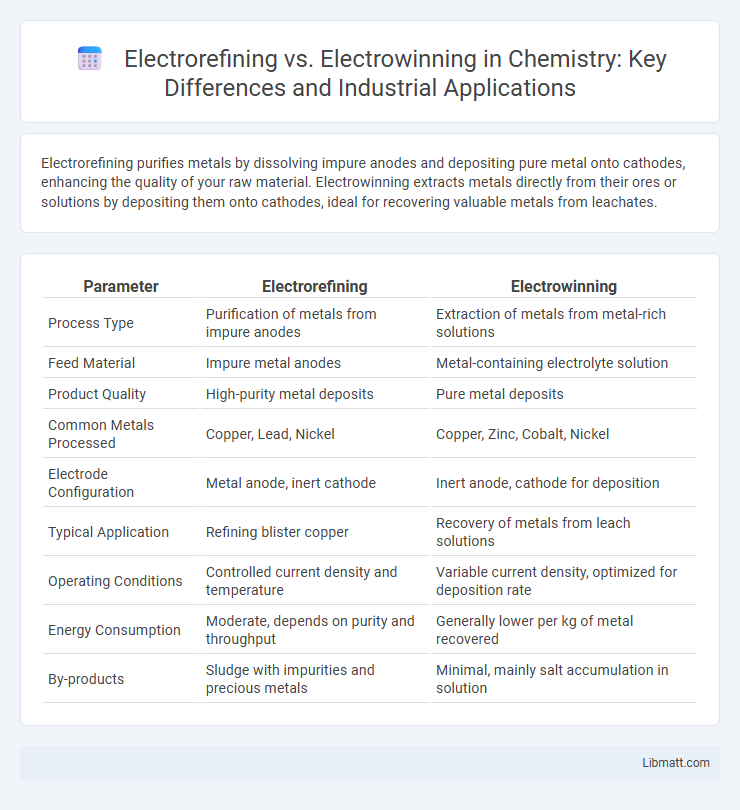

Electrorefining purifies metals by dissolving impure anodes and depositing pure metal onto cathodes, enhancing the quality of your raw material. Electrowinning extracts metals directly from their ores or solutions by depositing them onto cathodes, ideal for recovering valuable metals from leachates.

Table of Comparison

| Parameter | Electrorefining | Electrowinning |

|---|---|---|

| Process Type | Purification of metals from impure anodes | Extraction of metals from metal-rich solutions |

| Feed Material | Impure metal anodes | Metal-containing electrolyte solution |

| Product Quality | High-purity metal deposits | Pure metal deposits |

| Common Metals Processed | Copper, Lead, Nickel | Copper, Zinc, Cobalt, Nickel |

| Electrode Configuration | Metal anode, inert cathode | Inert anode, cathode for deposition |

| Typical Application | Refining blister copper | Recovery of metals from leach solutions |

| Operating Conditions | Controlled current density and temperature | Variable current density, optimized for deposition rate |

| Energy Consumption | Moderate, depends on purity and throughput | Generally lower per kg of metal recovered |

| By-products | Sludge with impurities and precious metals | Minimal, mainly salt accumulation in solution |

Introduction to Electrorefining and Electrowinning

Electrorefining and electrowinning are essential electrochemical processes used for metal purification and extraction, respectively. Electrorefining purifies impure metals by using an electrolytic cell to dissolve the anode and deposit pure metal onto the cathode, commonly applied in copper and nickel refining. Electrowinning extracts metals from their ore solutions by electrodeposition, widely used for metals such as gold, silver, and copper in hydrometallurgical operations.

Fundamental Principles of Electrorefining

Electrorefining involves the purification of metals by using an electrolytic cell where the impure metal acts as the anode and pure metal is deposited at the cathode through oxidation and reduction reactions. The process relies on selective dissolution of the impure metal into the electrolyte, leaving impurities behind as sludge or remaining in solution. This method is widely applied in refining metals like copper, where high purity and metal recovery efficiency are essential.

Core Processes in Electrowinning

Electrowinning involves the core process of extracting metals from a solution by applying an electrical current that causes metal ions to deposit onto cathodes, forming pure metal sheets. This technique uses an electrolytic cell where the metal ions are reduced at the cathode, while impurities remain in the electrolyte or form sludge at the anode. Your choice between electrorefining and electrowinning depends on whether you are purifying an existing metal or recovering metal from a leach solution.

Key Differences Between Electrorefining and Electrowinning

Electrorefining purifies metals by using an impure metal anode and a pure metal cathode, allowing contaminants to separate during the electrochemical process, while electrowinning extracts metals from an electrolyte solution onto a cathode. In electrorefining, the goal is to improve metal purity, typically for copper or silver, whereas electrowinning primarily recovers metal from leach solutions, such as gold or zinc. Understanding these key differences can help you select the appropriate method for your metal recovery or purification needs.

Advantages of Electrorefining

Electrorefining offers precise purification of metals by selectively removing impurities, resulting in higher purity levels compared to electrowinning. It provides superior control over the deposition process, enhancing the quality and consistency of the refined metal. Your choice of electrorefining ensures efficient recovery of valuable metals from impure sources with minimal loss.

Benefits of Electrowinning

Electrowinning offers significant benefits, including higher purity metal recovery and greater energy efficiency compared to electrorefining. The process allows you to extract metals directly from solutions without the need for intermediate steps, reducing operational costs and processing time. Its scalability and ability to handle lower-grade ores make electrowinning an ideal choice for sustainable and cost-effective metal extraction.

Industrial Applications of Both Techniques

Electrorefining and electrowinning are essential in metal recovery and purification industries, with electrorefining primarily used for refining copper, nickel, and silver to achieve high-purity metals for electronics and coinage. Electrowinning plays a crucial role in extracting metals like copper, zinc, and gold directly from aqueous solutions in mining and metal processing operations. Your choice between these techniques depends on the desired metal purity and the specific industrial application, as electrorefining offers precise impurity removal while electrowinning excels in cost-effective metal extraction.

Energy Consumption and Efficiency Comparison

Electrorefining typically consumes less energy per unit of metal produced than electrowinning due to its more selective deposition process and ability to purify metals in a single step. Electrowinning often requires higher current densities and longer operational times, increasing overall energy consumption but can be more efficient for low-grade ores or solutions. Your choice between these methods should consider the specific energy efficiency and purity requirements of your production goals.

Environmental Impact Analysis

Electrorefining and electrowinning both offer environmentally friendly metal recovery methods, but electrorefining typically produces fewer impurities and reduces hazardous waste due to its selective purification process. Your choice impacts waste management, as electrowinning can generate more sludge that requires careful disposal to prevent soil and water contamination. Optimizing these processes minimizes energy consumption and lowers the carbon footprint associated with metal extraction.

Future Trends in Electrorefining and Electrowinning

Future trends in electrorefining and electrowinning emphasize increased efficiency and sustainability, with advanced electrode materials and automated control systems enhancing metal purity and energy consumption. Innovations such as digital monitoring and AI-driven process optimization are expected to revolutionize these techniques, enabling more precise and cost-effective recovery of valuable metals like copper, zinc, and gold. Your operations can benefit from integrating these cutting-edge technologies to meet growing demand for environmentally friendly metal extraction processes.

Electrorefining vs electrowinning Infographic

libmatt.com

libmatt.com