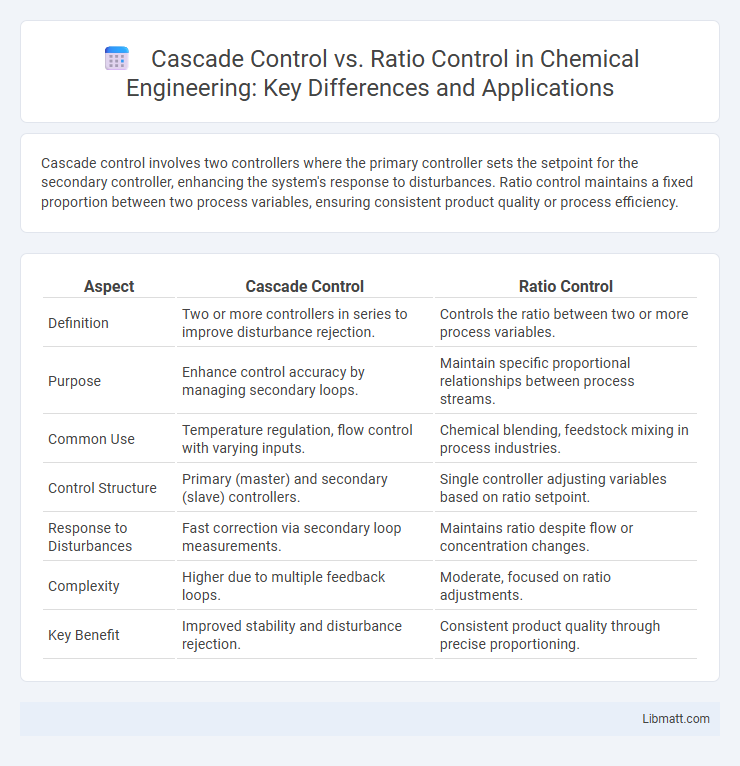

Cascade control involves two controllers where the primary controller sets the setpoint for the secondary controller, enhancing the system's response to disturbances. Ratio control maintains a fixed proportion between two process variables, ensuring consistent product quality or process efficiency.

Table of Comparison

| Aspect | Cascade Control | Ratio Control |

|---|---|---|

| Definition | Two or more controllers in series to improve disturbance rejection. | Controls the ratio between two or more process variables. |

| Purpose | Enhance control accuracy by managing secondary loops. | Maintain specific proportional relationships between process streams. |

| Common Use | Temperature regulation, flow control with varying inputs. | Chemical blending, feedstock mixing in process industries. |

| Control Structure | Primary (master) and secondary (slave) controllers. | Single controller adjusting variables based on ratio setpoint. |

| Response to Disturbances | Fast correction via secondary loop measurements. | Maintains ratio despite flow or concentration changes. |

| Complexity | Higher due to multiple feedback loops. | Moderate, focused on ratio adjustments. |

| Key Benefit | Improved stability and disturbance rejection. | Consistent product quality through precise proportioning. |

Introduction to Cascade Control and Ratio Control

Cascade control employs two or more controllers in a hierarchical structure, where the primary controller adjusts the setpoint of a secondary controller to enhance system stability and response time. Ratio control maintains a specific proportional relationship between two process variables, often used to ensure precise mixing or blending ratios in industrial processes. Understanding your process requirements determines whether cascade control's layered approach or ratio control's fixed proportionality best optimizes system performance.

Basic Principles of Cascade Control

Cascade control utilizes two controllers in series, where the primary controller regulates the setpoint of the secondary controller to enhance system stability and disturbance rejection. The primary controller addresses the main process variable while the secondary controller manages an intermediate variable, resulting in improved control accuracy and faster response times. This hierarchical structure reduces the impact of disturbances by isolating them within the secondary loop before they affect the primary process variable.

Fundamentals of Ratio Control

Ratio control maintains a specific proportional relationship between two process variables by adjusting one variable based on the set ratio and the measured value of the other. It uses a fixed multiplier to ensure consistent product quality, especially in blending or chemical reactions, where precise material proportions are critical. Your process efficiency improves as ratio control minimizes variations and optimizes feedstock inputs automatically.

Key Differences Between Cascade and Ratio Control

Cascade control uses a primary controller to regulate a secondary controller, enhancing system stability by managing disturbances within a complex process, while ratio control maintains a fixed proportion between two variables, ensuring a consistent mix or blend. Cascade control is ideal for processes with interacting variables requiring precise disturbance rejection, whereas ratio control excels in applications demanding accurate proportional relationships, such as chemical blending or fuel-air mixtures. Your choice depends on whether the priority is handling dynamic process interactions or maintaining fixed ratios.

Application Areas of Cascade Control

Cascade control is widely applied in industries requiring precise temperature regulation, such as chemical processing and power plants, where controlling multiple interdependent variables enhances system stability. It is essential in HVAC systems for maintaining consistent climate conditions by managing primary and secondary control loops simultaneously. This control strategy improves performance in processes like distillation and heat exchangers by enabling faster response to disturbances and reducing offset errors.

Typical Use Cases for Ratio Control

Ratio control is typically used in chemical processing industries to maintain a precise proportion between two or more process variables, such as mixing fuels and air in combustion systems or blending raw materials in manufacturing. It ensures consistent product quality by maintaining the desired ratio regardless of flow changes or disturbances in one of the streams. This control strategy is essential in applications like wastewater treatment, chemical reactors, and food processing where accurate component ratios directly impact process efficiency and output quality.

Advantages of Cascade Control Systems

Cascade control systems offer improved disturbance rejection by utilizing a primary and secondary controller, enabling faster response to process changes and minimizing variability. This multi-level control approach enhances stability in processes with significant lag or complex dynamics, ensuring more precise regulation of key parameters. Your operations benefit from increased accuracy and reduced oscillations compared to ratio control, which typically manages only proportional throughput without addressing dynamic disturbances effectively.

Benefits of Implementing Ratio Control

Implementing ratio control enhances process accuracy by maintaining precise proportional relationships between key variables, reducing variability and improving product consistency. This control strategy optimizes resource use and energy efficiency by dynamically adjusting flow rates or concentrations based on real-time process conditions. Your system achieves better responsiveness to disturbances compared to cascade control, resulting in more stable and efficient operations.

Challenges and Limitations of Each Control Strategy

Cascade control faces challenges such as complexity in tuning multiple controllers, potential interaction issues between the primary and secondary loops, and increased maintenance requirements. Ratio control struggles with limitations including the need for precise measurement of process variables, difficulties in handling disturbances that affect the ratio, and reduced effectiveness when one of the process variables is highly dynamic or nonlinear. Both strategies require careful implementation to avoid performance degradation and ensure stable process operation.

Choosing the Right Control Method for Your Process

Cascade control enhances system stability by using two controllers in series, ideal for processes with significant disturbances and slower dynamics. Ratio control maintains a fixed proportion between two variables, making it suitable for predictable, steady-state blending or mixing operations. Your choice depends on process complexity, disturbance levels, and control precision requirements.

Cascade control vs ratio control Infographic

libmatt.com

libmatt.com