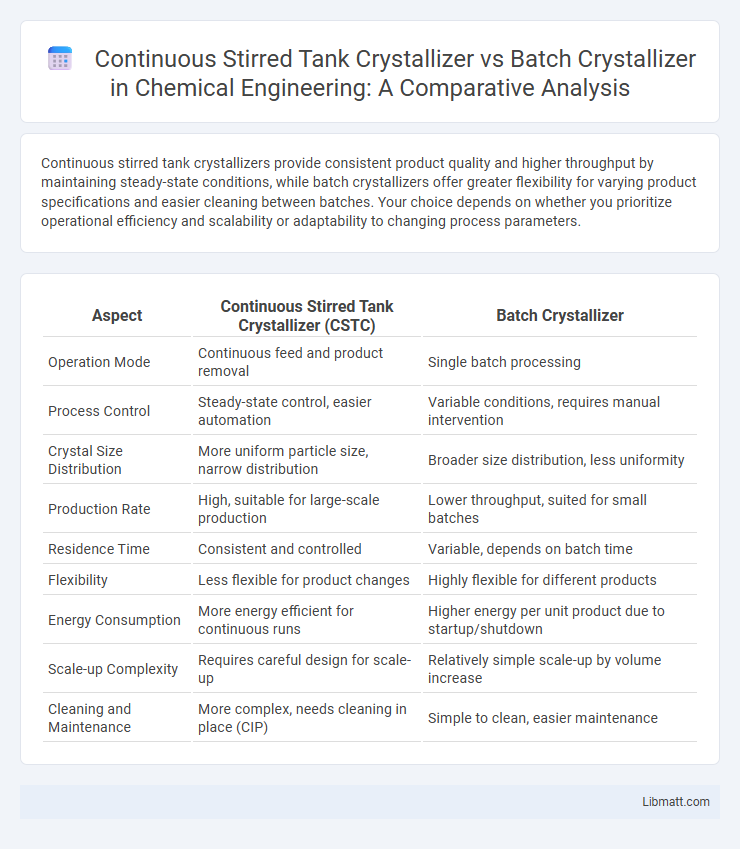

Continuous stirred tank crystallizers provide consistent product quality and higher throughput by maintaining steady-state conditions, while batch crystallizers offer greater flexibility for varying product specifications and easier cleaning between batches. Your choice depends on whether you prioritize operational efficiency and scalability or adaptability to changing process parameters.

Table of Comparison

| Aspect | Continuous Stirred Tank Crystallizer (CSTC) | Batch Crystallizer |

|---|---|---|

| Operation Mode | Continuous feed and product removal | Single batch processing |

| Process Control | Steady-state control, easier automation | Variable conditions, requires manual intervention |

| Crystal Size Distribution | More uniform particle size, narrow distribution | Broader size distribution, less uniformity |

| Production Rate | High, suitable for large-scale production | Lower throughput, suited for small batches |

| Residence Time | Consistent and controlled | Variable, depends on batch time |

| Flexibility | Less flexible for product changes | Highly flexible for different products |

| Energy Consumption | More energy efficient for continuous runs | Higher energy per unit product due to startup/shutdown |

| Scale-up Complexity | Requires careful design for scale-up | Relatively simple scale-up by volume increase |

| Cleaning and Maintenance | More complex, needs cleaning in place (CIP) | Simple to clean, easier maintenance |

Introduction to Crystallization Processes

Continuous stirred tank crystallizers maintain steady-state conditions that enable consistent crystal size distribution and improved scalability, making them ideal for large-scale industrial applications. Batch crystallizers offer greater flexibility for processing varying formulations and precise control over nucleation and growth phases, suitable for small-scale or specialized production. Both methods leverage supersaturation and temperature control to optimize crystal purity and yield in chemical and pharmaceutical manufacturing.

Overview of Continuous Stirred Tank Crystallizer (CSTC)

The Continuous Stirred Tank Crystallizer (CSTC) operates with a constant feed and withdrawal system, maintaining steady-state conditions that enhance uniform crystal size distribution and improved product quality. Key parameters such as supersaturation, temperature, and stir rate are precisely controlled to optimize nucleation and crystal growth rates. CSTCs offer advantages in scaling up processes due to their consistent operation and ability to handle continuous production demands in industries like pharmaceuticals and fine chemicals.

Overview of Batch Crystallizer

Batch crystallizers operate by processing a fixed volume of solution where nucleation and crystal growth occur over a set time, allowing precise control over crystal size and purity. They are favored for producing specialty chemicals and pharmaceuticals due to their flexibility in handling varying formulations and ease of cleaning between batches. Unlike continuous stirred tank crystallizers, batch systems do not run continuously, making them suitable for small-scale or intermittent production processes.

Key Design Differences: CSTC vs Batch Crystallizer

Continuous stirred tank crystallizers (CSTCs) feature steady-state operation with constant feed and product withdrawal, enabling uniform supersaturation and consistent crystal size distribution. Batch crystallizers operate in distinct processing cycles with varying supersaturation levels, allowing greater flexibility in controlling nucleation and growth phases but often resulting in broader crystal size distribution. Key design differences include CSTCs' emphasis on hydraulic residence time and continuous mixing, whereas batch crystallizers focus on batch volume control and timed agitation for optimized crystal morphology.

Operational Principles and Process Control

Continuous stirred tank crystallizers operate with a steady feed and product removal, maintaining constant supersaturation and crystal growth conditions, which allows for precise control of crystal size distribution through continuous monitoring of parameters like temperature, concentration, and agitation speed. Batch crystallizers rely on time-dependent changes in supersaturation and typically require manual adjustments of cooling or evaporation rates, making process control more variable and dependent on operator experience. Your choice between the two should consider the need for consistent product quality and ease of automation, as continuous systems offer better stability and scalability in operational control.

Product Quality and Crystal Size Distribution

Continuous stirred tank crystallizers offer superior control over product quality due to stable operating conditions, enabling consistent crystal size distribution with narrower particle size range. Batch crystallizers tend to exhibit greater variability in crystal size distribution because of changing supersaturation and mixing patterns during the process. Optimizing parameters like agitation speed and cooling rate in continuous systems enhances uniform crystal morphology and purity, critical for pharmaceutical and fine chemical applications.

Efficiency and Throughput Comparison

Continuous stirred tank crystallizers (CSTCs) offer higher throughput and more consistent product quality due to their steady-state operation, enabling efficient heat and mass transfer. Batch crystallizers, while flexible for small-scale or varied product runs, often experience variability in crystal size and longer downtime between batches, reducing overall efficiency. Selecting a CSTC can optimize your production processes by maximizing efficiency and ensuring continuous output.

Scalability and Industrial Applications

Continuous stirred tank crystallizers offer superior scalability due to their steady-state operation, making them ideal for large-scale industrial applications requiring consistent product quality and high throughput. Batch crystallizers provide greater flexibility for varied product specifications but are less efficient for scaling up because of longer processing times and downtime between batches. Your choice depends on production volume needs and the desired balance between process control and operational efficiency.

Advantages and Limitations of CSTC and Batch Crystallizer

Continuous stirred tank crystallizers (CSTCs) offer advantages such as consistent product quality, enhanced control over crystal size distribution, and higher throughput suitable for large-scale production. Limitations of CSTCs include complex operational control and higher initial investment costs, making them less flexible for product changes. Batch crystallizers provide greater flexibility for varying products and simpler operation, but they suffer from lower productivity and inconsistent crystal quality due to batch-to-batch variations affecting Your manufacturing process.

Choosing the Right Crystallizer: Factors to Consider

Selecting the right crystallizer depends on factors such as production scale, crystal size uniformity, and process control requirements. Continuous stirred tank crystallizers offer consistent product quality and scalability for large-scale operations, while batch crystallizers provide flexibility and ease of operation for smaller or variable production runs. Your choice should align with desired throughput, crystal purity, and operational complexity to optimize efficiency and product specifications.

continuous stirred tank crystallizer vs batch crystallizer Infographic

libmatt.com

libmatt.com