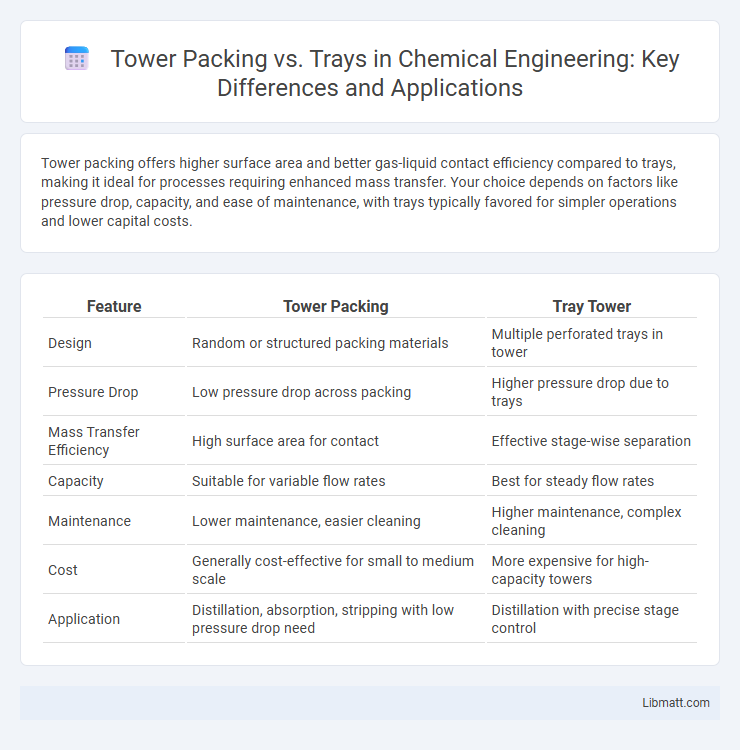

Tower packing offers higher surface area and better gas-liquid contact efficiency compared to trays, making it ideal for processes requiring enhanced mass transfer. Your choice depends on factors like pressure drop, capacity, and ease of maintenance, with trays typically favored for simpler operations and lower capital costs.

Table of Comparison

| Feature | Tower Packing | Tray Tower |

|---|---|---|

| Design | Random or structured packing materials | Multiple perforated trays in tower |

| Pressure Drop | Low pressure drop across packing | Higher pressure drop due to trays |

| Mass Transfer Efficiency | High surface area for contact | Effective stage-wise separation |

| Capacity | Suitable for variable flow rates | Best for steady flow rates |

| Maintenance | Lower maintenance, easier cleaning | Higher maintenance, complex cleaning |

| Cost | Generally cost-effective for small to medium scale | More expensive for high-capacity towers |

| Application | Distillation, absorption, stripping with low pressure drop need | Distillation with precise stage control |

Introduction to Mass Transfer Equipment

Mass transfer equipment, such as tower packing and trays, plays a crucial role in chemical processing by enhancing contact between vapor and liquid phases for efficient separation. Tower packing offers high surface area and low pressure drop, making it ideal for handling corrosive or fouling fluids, while trays provide well-defined stages and are suitable for precise vapor-liquid separation. Understanding these options helps optimize your process design for improved mass transfer efficiency and operational flexibility.

Overview of Tower Packing

Tower packing enhances mass transfer efficiency by providing a structured surface area for vapor and liquid interaction, optimizing gas absorption and distillation processes. Compared to trays, tower packing reduces pressure drop and improves liquid distribution, leading to lower energy consumption and higher throughput. Understanding the specific requirements of your process helps in selecting the ideal packing type, maximizing performance and cost-effectiveness.

Overview of Trays in Distillation Columns

Trays in distillation columns serve as horizontal stages where vapor and liquid phases contact, facilitating mass transfer for separation. Each tray promotes efficient vapor-liquid equilibrium, enhancing the column's separation efficiency and capacity. Your choice of trays affects pressure drop, throughput, and operational flexibility compared to tower packing alternatives.

Key Differences Between Packing and Tray Columns

Tower packing utilizes structured or random packing materials to enhance gas-liquid contact and mass transfer efficiency, whereas tray columns rely on perforated or bubble-cap trays to facilitate phase interaction. Packing columns offer lower pressure drops and better performance in handling fouling or viscous fluids, while tray columns provide easier maintenance and scalability for varying operational conditions. Selection depends on factors like capacity, pressure drop, fouling tendency, and separation efficiency requirements in chemical or petroleum industries.

Efficiency Comparison: Packing vs Trays

Tower packing offers higher efficiency by providing greater surface area for mass transfer within a compact volume, resulting in improved gas-liquid contact and lower pressure drop compared to trays. Trays, while easier to maintain and scale, typically have lower throughput capacities and higher energy consumption. Your choice depends on balancing operational flexibility with optimal separation performance.

Pressure Drop Analysis: Packing vs Trays

Pressure drop analysis reveals that tower packing generally offers lower pressure drops compared to trays, enhancing energy efficiency in fluid processing systems. You experience reduced operational costs and less mechanical stress with packing due to its open structure and minimized flow resistance. In contrast, trays create higher pressure drops because of liquid weirs and vapor-liquid interaction, which can lead to increased energy consumption and potential flooding risks.

Cost Considerations for Tower Packing and Trays

Tower packing often involves higher initial costs due to specialized materials and installation complexity, but it typically offers better efficiency and longevity, reducing long-term operational expenses. Trays generally have lower upfront costs and simpler maintenance but may incur higher pressure drops and reduced mass transfer efficiency, leading to increased energy consumption. Evaluating life-cycle costs, including installation, maintenance, and energy use, is crucial when choosing between tower packing and trays in industrial applications.

Suitability for Different Applications

Tower packing is ideal for applications requiring high mass transfer efficiency and low-pressure drop, such as distillation and absorption in chemical processing. Trays suit operations with high liquid loads and solids handling, commonly used in refinery fractionation and wastewater treatment. Your choice depends on specific process needs, including capacity, fouling potential, and maintenance requirements.

Maintenance and Operational Factors

Tower packing requires more frequent inspection and cleaning to prevent fouling and maintain efficiency, while trays are generally easier to clean and inspect due to their access-friendly design. Maintenance of tower packing can be more labor-intensive, often necessitating specialized equipment to remove or replace damaged packing elements. Operationally, trays provide better operational flexibility under varying flow rates, whereas packing offers lower pressure drop but may demand more rigorous operational monitoring to avoid channeling or flooding.

Choosing the Right Solution for Your Process

Selecting between tower packing and trays depends on factors like efficiency, pressure drop, and capacity for the specific process. Tower packing offers lower pressure drop and higher surface area, ideal for mass transfer in distillation or absorption with sensitive pressure constraints. Trays provide robust mechanical strength and easy maintenance, suited for high liquid loads and processes requiring precise stage control.

tower packing vs trays Infographic

libmatt.com

libmatt.com