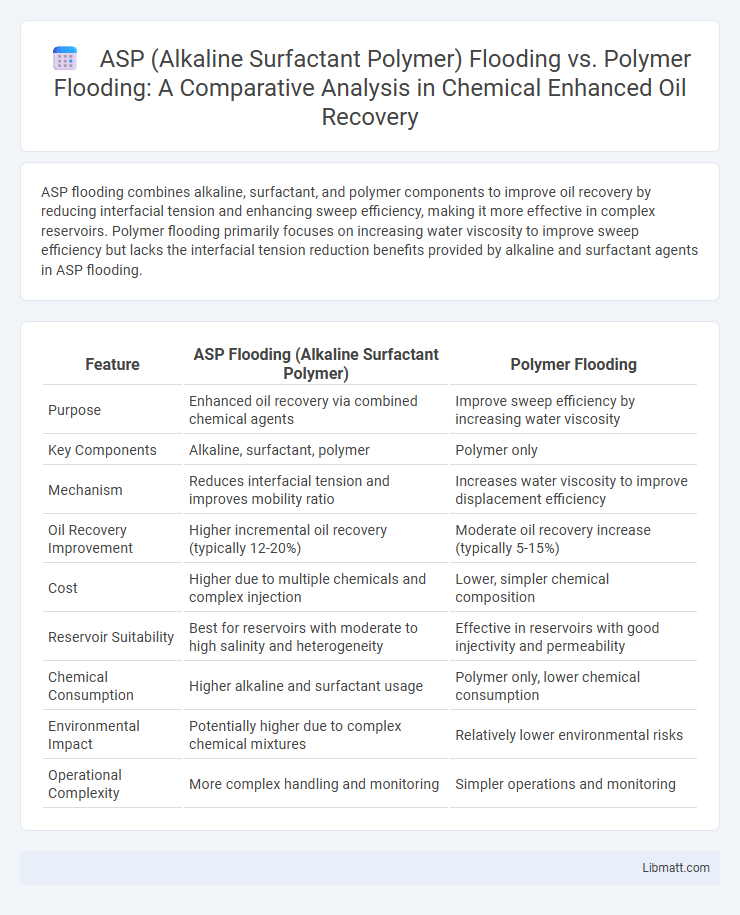

ASP flooding combines alkaline, surfactant, and polymer components to improve oil recovery by reducing interfacial tension and enhancing sweep efficiency, making it more effective in complex reservoirs. Polymer flooding primarily focuses on increasing water viscosity to improve sweep efficiency but lacks the interfacial tension reduction benefits provided by alkaline and surfactant agents in ASP flooding.

Table of Comparison

| Feature | ASP Flooding (Alkaline Surfactant Polymer) | Polymer Flooding |

|---|---|---|

| Purpose | Enhanced oil recovery via combined chemical agents | Improve sweep efficiency by increasing water viscosity |

| Key Components | Alkaline, surfactant, polymer | Polymer only |

| Mechanism | Reduces interfacial tension and improves mobility ratio | Increases water viscosity to improve displacement efficiency |

| Oil Recovery Improvement | Higher incremental oil recovery (typically 12-20%) | Moderate oil recovery increase (typically 5-15%) |

| Cost | Higher due to multiple chemicals and complex injection | Lower, simpler chemical composition |

| Reservoir Suitability | Best for reservoirs with moderate to high salinity and heterogeneity | Effective in reservoirs with good injectivity and permeability |

| Chemical Consumption | Higher alkaline and surfactant usage | Polymer only, lower chemical consumption |

| Environmental Impact | Potentially higher due to complex chemical mixtures | Relatively lower environmental risks |

| Operational Complexity | More complex handling and monitoring | Simpler operations and monitoring |

Introduction to ASP and Polymer Flooding

ASP (alkaline surfactant polymer) flooding enhances oil recovery by combining alkaline agents, surfactants, and polymers to reduce interfacial tension and improve fluid mobility within reservoirs. Polymer flooding primarily involves injecting polymer solutions to increase water viscosity, improving sweep efficiency and displacing more oil. Understanding your reservoir's characteristics is crucial for selecting between ASP and polymer flooding to maximize oil extraction efficiency.

Fundamentals of Enhanced Oil Recovery (EOR)

Alkaline surfactant polymer (ASP) flooding enhances oil recovery by combining alkali, surfactant, and polymer to improve oil displacement efficiency, reduce interfacial tension, and increase sweep efficiency in reservoirs. Polymer flooding primarily focuses on increasing water viscosity to improve sweep efficiency and mobility control, preventing early water breakthrough. Your EOR strategy benefits from understanding that ASP flooding addresses multiple recovery mechanisms simultaneously, making it more effective in heterogeneous reservoirs compared to polymer flooding alone.

Chemical Composition and Mechanisms

Alkaline Surfactant Polymer (ASP) flooding combines alkali, surfactant, and polymer components to enhance oil recovery by reducing interfacial tension, altering wettability, and improving mobility control, whereas Polymer flooding primarily utilizes high-molecular-weight polymers to increase water viscosity and improve sweep efficiency. The chemical composition of ASP includes alkali agents such as sodium carbonate, surfactants like sulfonates or nonionic types, and polymers such as partially hydrolyzed polyacrylamide (HPAM), working synergistically to mobilize trapped oil. Polymer flooding relies mainly on polymers that increase the displacing fluid's viscosity, minimizing fingering phenomena and enhancing macroscopic sweep efficiency without directly modifying interfacial properties.

Reservoir Suitability and Screening Criteria

ASP (alkaline surfactant polymer) flooding is most suitable for reservoirs with moderate to high permeability, favorable wettability, and presence of heavy or viscous oil, as the alkaline component reduces interfacial tension and the surfactant-polymer combination enhances oil recovery. Polymer flooding requires reservoirs with good injectivity, relatively homogeneous geology, and low to moderate salinity to maintain polymer viscosity and mobility control. Screening criteria for ASP include reservoir temperature below 90degC, clay content under 20%, and compatibility with reservoir brine chemistry, while polymer flooding prefers temperatures below 80degC and minimal polymer adsorption for efficient displacement.

Performance Comparison: ASP vs Polymer Flooding

ASP (alkaline surfactant polymer) flooding enhances oil recovery by combining the effects of alkalinity, surfactants, and polymers to reduce interfacial tension and improve sweep efficiency, resulting in higher recovery factors compared to polymer flooding alone. Polymer flooding primarily increases oil displacement by improving water viscosity and mobility control but lacks the interfacial tension reduction benefits of surfactants and alkalinity present in ASP. Your choice between ASP and polymer flooding depends on reservoir conditions, with ASP generally offering superior performance in reservoirs where chemical synergy can be fully leveraged.

Operational Challenges and Solutions

ASP (alkaline surfactant polymer) flooding faces operational challenges such as chemical precipitation, scale formation, and complex fluid compatibility issues, which can lead to injection system clogging and reduced recovery efficiency. Polymer flooding primarily encounters challenges related to polymer degradation, viscosity loss, and injectivity reduction caused by reservoir heterogeneity and shear forces. Implementing real-time monitoring systems, optimizing chemical formulations for reservoir conditions, and employing pre-treatment techniques can help mitigate these issues and improve your flood performance.

Economic Considerations and Project Viability

ASP (alkaline surfactant polymer) flooding generally requires higher upfront capital investment due to the cost of chemicals and complex injection strategies, potentially impacting your project's economic feasibility. Polymer flooding typically offers a lower-cost alternative with simpler implementation and reduced operational expenses, making it more attractive for projects with tighter budgets. Evaluating reservoir characteristics and recovery goals is crucial to determine which method maximizes economic returns and long-term project viability.

Environmental Impacts and Sustainability

Alkaline Surfactant Polymer (ASP) flooding enhances oil recovery by combining alkaline agents, surfactants, and polymers, leading to effective reduction of interfacial tension and improved sweep efficiency, but the use of alkalis can cause issues such as high pH wastewater requiring careful disposal to mitigate environmental harm. Polymer flooding primarily involves injecting polymers to increase water viscosity and improve oil displacement with generally lower chemical complexity, resulting in fewer environmental concerns compared to ASP, particularly regarding wastewater treatment and chemical degradation. Sustainable implementation of both methods demands optimization of chemical dosages, use of biodegradable polymers, and robust environmental management practices to minimize ecological footprint and ensure regulatory compliance.

Case Studies and Field Applications

ASP (alkaline surfactant polymer) flooding has demonstrated significant enhanced oil recovery (EOR) potential in case studies like China's Daqing oilfield, where incremental recovery rates exceeded 15%. Polymer flooding, widely applied in fields such as the North Sea and Canada, typically improves oil recovery by 5-10% through increased sweep efficiency and mobility control. Your choice between ASP and polymer flooding should consider reservoir conditions, as ASP is more effective in high-salinity and high-temperature environments demonstrated in field applications.

Future Trends in Chemical EOR Technologies

Future trends in chemical EOR technologies highlight the growing adoption of ASP (alkaline surfactant polymer) flooding due to its enhanced oil recovery efficiency by reducing interfacial tension and improving sweep efficiency. Polymer flooding remains a cornerstone technique, with advancements focusing on high-temperature and salinity-tolerant polymers to optimize viscosity control in complex reservoir conditions. Your investment in these evolving chemical formulations can significantly improve recovery factors and reduce environmental impact as industry moves toward more sustainable and cost-effective EOR solutions.

ASP (alkaline surfactant polymer) vs Polymer flooding Infographic

libmatt.com

libmatt.com