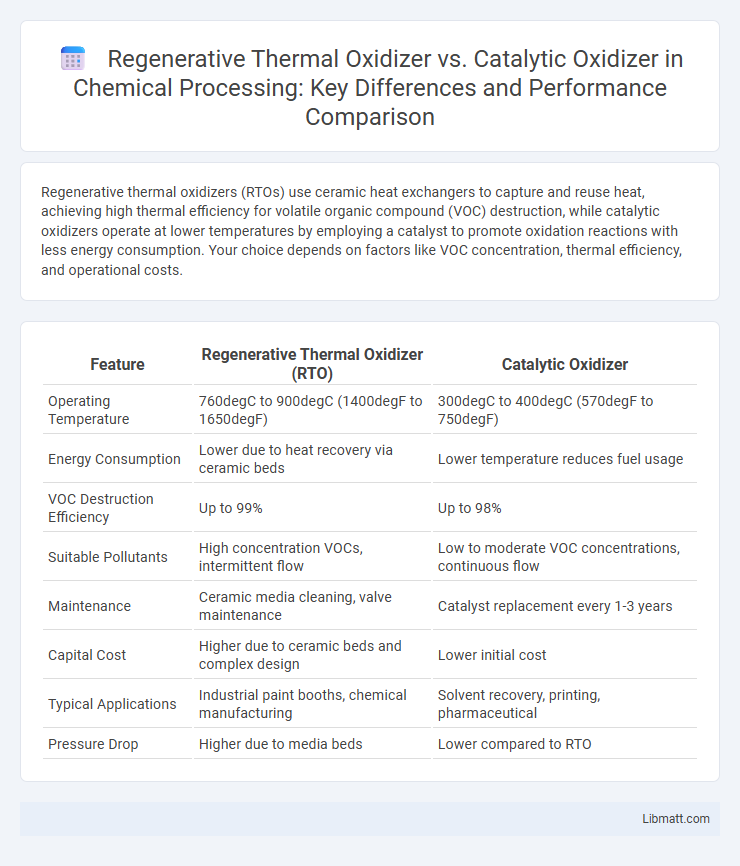

Regenerative thermal oxidizers (RTOs) use ceramic heat exchangers to capture and reuse heat, achieving high thermal efficiency for volatile organic compound (VOC) destruction, while catalytic oxidizers operate at lower temperatures by employing a catalyst to promote oxidation reactions with less energy consumption. Your choice depends on factors like VOC concentration, thermal efficiency, and operational costs.

Table of Comparison

| Feature | Regenerative Thermal Oxidizer (RTO) | Catalytic Oxidizer |

|---|---|---|

| Operating Temperature | 760degC to 900degC (1400degF to 1650degF) | 300degC to 400degC (570degF to 750degF) |

| Energy Consumption | Lower due to heat recovery via ceramic beds | Lower temperature reduces fuel usage |

| VOC Destruction Efficiency | Up to 99% | Up to 98% |

| Suitable Pollutants | High concentration VOCs, intermittent flow | Low to moderate VOC concentrations, continuous flow |

| Maintenance | Ceramic media cleaning, valve maintenance | Catalyst replacement every 1-3 years |

| Capital Cost | Higher due to ceramic beds and complex design | Lower initial cost |

| Typical Applications | Industrial paint booths, chemical manufacturing | Solvent recovery, printing, pharmaceutical |

| Pressure Drop | Higher due to media beds | Lower compared to RTO |

Introduction to Air Pollution Control Technologies

Regenerative thermal oxidizers (RTOs) and catalytic oxidizers are advanced air pollution control technologies designed to destroy volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) from industrial emissions. RTOs utilize high-temperature combustion and ceramic heat exchange media to achieve thermal oxidation with energy efficiency exceeding 95%, while catalytic oxidizers employ a catalyst to lower combustion temperature, reducing fuel consumption and operational costs. Both technologies play crucial roles in meeting stringent environmental regulations by converting harmful pollutants into carbon dioxide and water vapor, effectively minimizing industrial air contaminants.

What is a Regenerative Thermal Oxidizer (RTO)?

A Regenerative Thermal Oxidizer (RTO) is an advanced air pollution control device designed to destruct hazardous volatile organic compounds (VOCs) and toxic air pollutants through high-temperature combustion. It utilizes a ceramic heat exchange bed to capture and recycle heat, achieving thermal efficiencies typically above 95%, significantly reducing fuel consumption. RTOs are favored in industrial applications for their energy-efficient operation and ability to handle varying VOC concentrations with minimal emissions.

How Does a Catalytic Oxidizer Work?

A catalytic oxidizer works by using a catalyst, typically made of ceramic or metal coated with precious metals like platinum or palladium, to lower the activation energy required for the oxidation of volatile organic compounds (VOCs). This process occurs at lower temperatures, generally between 500degF and 700degF, making it more energy-efficient compared to regenerative thermal oxidizers that operate at higher temperatures. The catalyst facilitates the chemical reaction, converting harmful VOCs into carbon dioxide and water vapor while minimizing thermal degradation and energy consumption.

Efficiency Comparison: RTO vs. Catalytic Oxidizer

Regenerative thermal oxidizers (RTOs) achieve destruction efficiencies between 95% to 99% by using ceramic heat exchange media to recover thermal energy, making them highly energy-efficient for volatile organic compounds (VOCs) removal. Catalytic oxidizers typically offer similar destruction efficiencies around 95% to 98% but operate at lower temperatures, using catalysts to reduce fuel consumption and enhance performance with less thermal stress. Your choice between RTO and catalytic oxidizer should consider factors like VOC concentration, temperature sensitivity, and energy costs to optimize efficiency and operational savings.

Energy Consumption and Operational Costs

Regenerative thermal oxidizers (RTOs) typically consume less energy than catalytic oxidizers due to their ability to recover up to 95% of the heat generated during the oxidation process, significantly reducing fuel requirements. Catalytic oxidizers operate at lower temperatures but require periodic catalyst replacement, which increases operational costs over time. The choice between RTOs and catalytic oxidizers hinges on balancing the higher initial fuel savings of RTOs against the ongoing maintenance and catalyst expenses of catalytic systems.

Suitability for Different Industrial Applications

Regenerative thermal oxidizers (RTOs) are highly suitable for industries with high-volume, low-concentration volatile organic compounds (VOCs), such as paint shops, printing, and chemical manufacturing, due to their energy efficiency and cost-effectiveness in handling large gas flows. Catalytic oxidizers excel in applications requiring lower operating temperatures and precise temperature control, making them ideal for pharmaceutical, food processing, and solvent recovery processes where delicate or temperature-sensitive compounds are involved. Selection between RTOs and catalytic oxidizers depends on factors like VOC concentration, thermal stability of compounds, and overall operational costs specific to industrial applications.

Maintenance Requirements and System Longevity

Regenerative thermal oxidizers (RTOs) demand routine inspection and cleaning of ceramic media beds to prevent fouling and maintain efficiency, with maintenance intervals varying based on contaminant load but generally extending system longevity beyond 15 years. Catalytic oxidizers require periodic catalyst replacement, typically every 3 to 5 years, as catalyst deactivation from contaminants reduces oxidation performance, influencing overall operational costs and system lifespan. Both systems benefit from proactive maintenance strategies; however, RTOs often exhibit longer service life due to robust construction and fewer consumable components compared to catalytic oxidizers.

Emission Reduction Capabilities

Regenerative thermal oxidizers (RTOs) achieve emission reduction efficiencies up to 99% by oxidizing volatile organic compounds (VOCs) at high temperatures with heat recovery systems that improve energy efficiency. Catalytic oxidizers reduce VOC emissions typically between 95% and 98% by utilizing catalysts to lower the oxidation temperature, enabling effective pollutant decomposition with less energy consumption. Both systems are effective for air pollution control, but RTOs are preferred for higher VOC concentrations and larger airflow volumes due to their superior thermal efficiency and lower operating costs.

Environmental Impact and Sustainability

Regenerative thermal oxidizers (RTOs) offer superior energy efficiency by recovering up to 95% of the heat generated, significantly reducing fuel consumption and greenhouse gas emissions compared to catalytic oxidizers. Catalytic oxidizers operate at lower temperatures and rely on catalysts, which may require periodic replacement and generate hazardous waste, impacting sustainability efforts. RTOs' higher thermal energy recovery and lower operational emissions make them a more environmentally sustainable choice for industrial air pollution control.

Key Factors in Choosing Between RTO and Catalytic Oxidizer

Key factors in choosing between a Regenerative Thermal Oxidizer (RTO) and a Catalytic Oxidizer include the nature of your volatile organic compounds (VOCs), operating temperature requirements, and energy efficiency. RTOs are ideal for high-volume gas streams with varying VOC concentrations, offering energy recovery through ceramic media, whereas Catalytic Oxidizers operate at lower temperatures using a catalyst to reduce thermal energy needs but require VOCs compatible with the catalyst. Consider your facility's specific emissions profile, maintenance capabilities, and operational costs to determine the most effective and sustainable solution for air pollution control.

Regenerative thermal oxidizer vs catalytic oxidizer Infographic

libmatt.com

libmatt.com