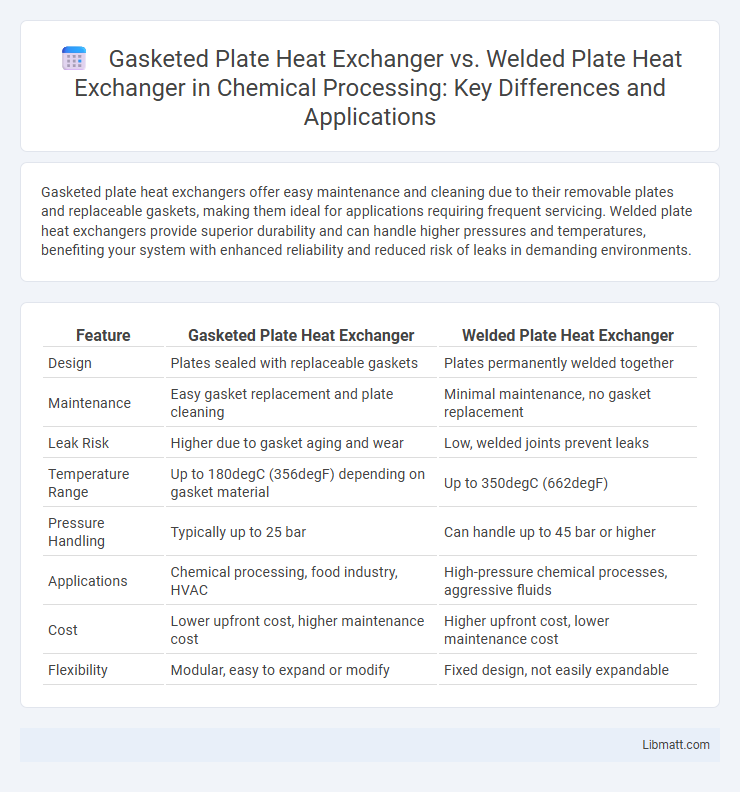

Gasketed plate heat exchangers offer easy maintenance and cleaning due to their removable plates and replaceable gaskets, making them ideal for applications requiring frequent servicing. Welded plate heat exchangers provide superior durability and can handle higher pressures and temperatures, benefiting your system with enhanced reliability and reduced risk of leaks in demanding environments.

Table of Comparison

| Feature | Gasketed Plate Heat Exchanger | Welded Plate Heat Exchanger |

|---|---|---|

| Design | Plates sealed with replaceable gaskets | Plates permanently welded together |

| Maintenance | Easy gasket replacement and plate cleaning | Minimal maintenance, no gasket replacement |

| Leak Risk | Higher due to gasket aging and wear | Low, welded joints prevent leaks |

| Temperature Range | Up to 180degC (356degF) depending on gasket material | Up to 350degC (662degF) |

| Pressure Handling | Typically up to 25 bar | Can handle up to 45 bar or higher |

| Applications | Chemical processing, food industry, HVAC | High-pressure chemical processes, aggressive fluids |

| Cost | Lower upfront cost, higher maintenance cost | Higher upfront cost, lower maintenance cost |

| Flexibility | Modular, easy to expand or modify | Fixed design, not easily expandable |

Introduction to Plate Heat Exchangers

Plate heat exchangers, including gasketed and welded types, are crucial for efficient thermal transfer in various industries. Gasketed plate heat exchangers feature removable plates sealed with gaskets, allowing easy maintenance and flexible capacity adjustments. Welded plate heat exchangers, with permanently sealed plates, provide higher pressure and temperature tolerance, ideal for demanding applications where leak prevention is critical.

Overview of Gasketed Plate Heat Exchangers

Gasketed plate heat exchangers feature removable plates sealed with gaskets, offering ease of maintenance and flexibility for capacity adjustments. These exchangers are ideal for applications requiring frequent cleaning or inspection, as the gaskets allow quick disassembly without specialized tools. Your choice of a gasketed plate heat exchanger ensures efficient heat transfer with the convenience of customization and repair.

Overview of Welded Plate Heat Exchangers

Welded plate heat exchangers consist of stainless steel plates permanently welded together, creating a robust and compact unit ideal for high-pressure and high-temperature applications. Their design ensures minimal leakage risk and excellent thermal efficiency, making them suitable for demanding industries like chemical processing and power generation. Your choice of a welded plate heat exchanger guarantees durability and superior heat transfer performance in challenging environments.

Key Design Differences

Gasketed plate heat exchangers feature removable plates held together by a frame with gaskets providing a tight seal, allowing easy maintenance and plate replacement. Welded plate heat exchangers have plates permanently fused by laser or brazing, creating a compact, leak-proof design ideal for high-pressure and high-temperature applications. Your choice depends on the required service conditions, maintenance preferences, and thermal efficiency needs.

Performance and Thermal Efficiency

Gasketed plate heat exchangers offer high thermal efficiency due to their flexible design that allows for easy maintenance and customization of plate arrangements, enhancing heat transfer performance. Welded plate heat exchangers provide superior performance in high-pressure and high-temperature applications by eliminating gaskets, which reduces the risk of leakage and allows for a more compact, durable design. Both types excel in thermal efficiency, but gasketed exchangers are preferred for systems requiring frequent cleaning, while welded units are optimal for demanding industrial environments with aggressive fluids.

Maintenance and Cleaning Considerations

Gasketed plate heat exchangers offer ease of maintenance and cleaning due to their removable plates, allowing for quick disassembly and inspection without specialized tools. In contrast, welded plate heat exchangers have a sealed design that prevents plate removal, making cleaning more challenging and often requiring chemical cleaning methods or complete replacement for fouling issues. Regular maintenance of gasketed units includes gasket inspection and replacement, whereas welded units demand thorough monitoring to avoid fouling that could compromise heat transfer efficiency.

Applications and Industry Use Cases

Gasketed plate heat exchangers excel in HVAC systems, food processing, and chemical plants due to their ease of maintenance and ability to handle moderate pressures and temperatures. Welded plate heat exchangers are preferred in demanding applications such as petrochemical, power generation, and marine industries, where high pressures, temperatures, and leakage prevention are critical. Choosing the right type impacts Your system's efficiency and operational reliability in industries ranging from pharmaceuticals to oil refining.

Pressure and Temperature Capabilities

Gasketed plate heat exchangers typically operate efficiently at pressures up to 25 bar and temperatures up to 180degC, making them suitable for moderate industrial applications. Welded plate heat exchangers are designed to withstand higher pressures, often exceeding 40 bar, and temperatures above 300degC, providing enhanced durability for demanding environments. Choosing between these options depends on Your system's pressure and temperature requirements to ensure optimal performance and longevity.

Cost Comparison and Long-term Value

Gasketed plate heat exchangers typically have lower upfront costs due to their modular design and ease of maintenance, making them economical for applications requiring frequent cleaning or adjustments. Welded plate heat exchangers involve higher initial investment but offer superior durability and leak-proof performance, reducing long-term downtime and maintenance expenses. Over time, welded variants provide better value in harsh or high-pressure environments, while gasketed versions remain cost-effective for lower-pressure, less demanding applications.

Choosing the Right Plate Heat Exchanger

Choosing the right plate heat exchanger depends on your specific application requirements, maintenance preferences, and operating conditions. Gasketed plate heat exchangers offer easy maintenance and flexibility due to removable plates, making them ideal for processes requiring frequent cleaning or adjustments. Welded plate heat exchangers provide higher pressure and temperature resistance with a compact design, suitable for demanding industrial applications where leakage prevention and durability are critical.

Gasketed plate heat exchanger vs welded plate heat exchanger Infographic

libmatt.com

libmatt.com