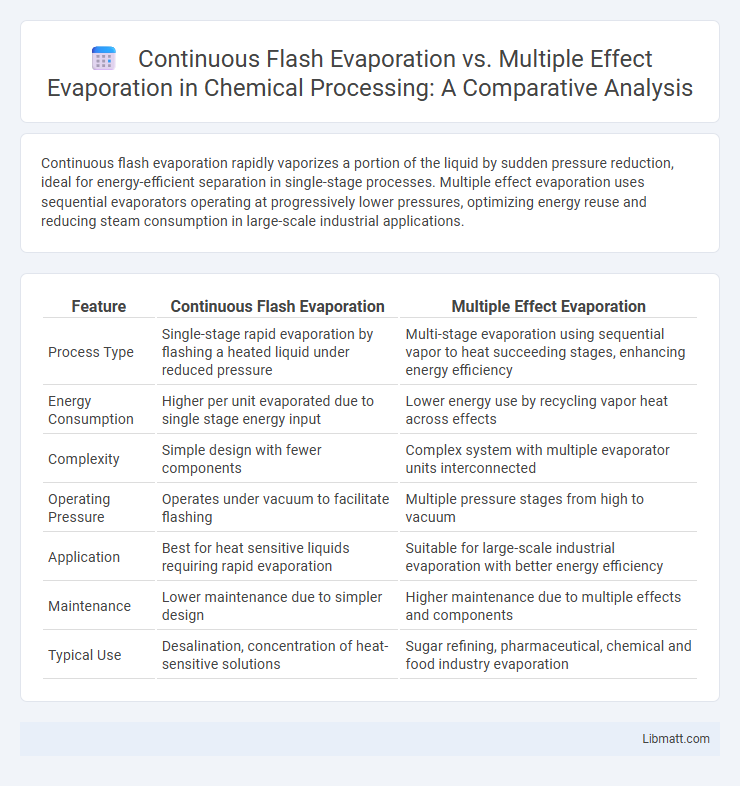

Continuous flash evaporation rapidly vaporizes a portion of the liquid by sudden pressure reduction, ideal for energy-efficient separation in single-stage processes. Multiple effect evaporation uses sequential evaporators operating at progressively lower pressures, optimizing energy reuse and reducing steam consumption in large-scale industrial applications.

Table of Comparison

| Feature | Continuous Flash Evaporation | Multiple Effect Evaporation |

|---|---|---|

| Process Type | Single-stage rapid evaporation by flashing a heated liquid under reduced pressure | Multi-stage evaporation using sequential vapor to heat succeeding stages, enhancing energy efficiency |

| Energy Consumption | Higher per unit evaporated due to single stage energy input | Lower energy use by recycling vapor heat across effects |

| Complexity | Simple design with fewer components | Complex system with multiple evaporator units interconnected |

| Operating Pressure | Operates under vacuum to facilitate flashing | Multiple pressure stages from high to vacuum |

| Application | Best for heat sensitive liquids requiring rapid evaporation | Suitable for large-scale industrial evaporation with better energy efficiency |

| Maintenance | Lower maintenance due to simpler design | Higher maintenance due to multiple effects and components |

| Typical Use | Desalination, concentration of heat-sensitive solutions | Sugar refining, pharmaceutical, chemical and food industry evaporation |

Introduction to Evaporation Technologies

Continuous flash evaporation rapidly vaporizes liquid by reducing pressure, enabling efficient heat transfer and energy conservation. Multiple effect evaporation uses a series of evaporators operating at decreasing pressures, reusing vapor energy to improve thermal efficiency and reduce operational costs. Your choice between these evaporation technologies depends on factors like feed composition, energy availability, and desired product concentration.

Principles of Continuous Flash Evaporation

Continuous flash evaporation operates by rapidly heating a liquid under reduced pressure to cause instant vaporization upon entering a lower pressure chamber, separating vapor and concentrate efficiently. This process leverages the abrupt pressure drop to achieve high evaporation rates with minimal thermal degradation, making it ideal for heat-sensitive liquids. You benefit from enhanced energy efficiency and reduced fouling compared to multiple effect evaporation systems.

Fundamentals of Multiple Effect Evaporation

Multiple Effect Evaporation (MEE) operates on the principle of using vapor generated from one evaporator effect as the heating medium for the next, significantly improving energy efficiency by cascading heat transfer across multiple stages. Each effect operates at progressively lower pressures, allowing the boiling point of the solution to decrease and enabling vapor reuse without additional energy input. This fundamental approach reduces steam consumption and operational costs compared to single-stage or Continuous Flash Evaporation systems.

Process Flow Comparison

Continuous flash evaporation involves a single-stage process where the feed liquid undergoes rapid pressure reduction, causing instantaneous vaporization and separation, resulting in simpler flow with a single vapor and liquid exit. Multiple effect evaporation uses a series of evaporators operating at progressively lower pressures, where vapor from one effect serves as the heating medium for the next, creating a complex flow pattern with multiple vapor and liquid streams. Your choice depends on whether a straightforward, fast separation or a more energy-efficient, staged evaporation process better suits your application.

Energy Efficiency Analysis

Continuous flash evaporation (CFE) offers higher energy efficiency by utilizing the flash evaporation process to rapidly vaporize a portion of the liquid, minimizing heat losses and reducing steam consumption compared to multiple effect evaporation (MEE). Multiple effect evaporation conserves energy by reusing vapor from one effect as the heating medium for the next, significantly lowering overall steam demand, especially in operations requiring large-scale liquid concentration. Your choice between CFE and MEE should consider process scale, energy costs, and desired evaporation rates, as MEE generally achieves better energy efficiency in extensive industrial applications.

Equipment Design Differences

Continuous flash evaporation systems utilize a single-stage process where liquid rapidly vaporizes upon pressure reduction, requiring compact, high-pressure vessels designed for rapid phase change and efficient vapor separation. Multiple effect evaporation involves several interconnected evaporators operating at progressively lower pressures, demanding complex equipment with multiple heat exchangers and condensers to recycle energy and maximize thermal efficiency. Your choice between these designs influences operational complexity, energy consumption, and maintenance requirements based on the specific evaporation capacity and feed characteristics.

Operational Considerations

Continuous flash evaporation operates with steady-state conditions ideal for handling large volumes of feedwater, resulting in consistent vapor quality and energy efficiency. Multiple effect evaporation requires careful management of inter-stage temperatures and pressure differences to maximize heat recovery and minimize steam consumption. Your choice depends on operational flexibility, maintenance demands, and the specific thermodynamic properties of the feed solution.

Applications in Industry

Continuous flash evaporation is widely used in desalination plants and chemical process industries where rapid phase change and high throughput are essential. Multiple effect evaporation, favored in food processing, pharmaceuticals, and sugar refining, optimizes energy consumption by utilizing steam through sequential stages, making it ideal for large-scale operations. Your choice between these methods depends on the balance between energy efficiency and operational speed required for the specific industrial application.

Economic and Environmental Impact

Continuous flash evaporation (CFE) offers lower energy consumption compared to multiple effect evaporation (MEE), translating to reduced operating costs and a smaller carbon footprint. MEE systems, while initially more expensive due to higher capital investment, provide greater thermal efficiency by reutilizing steam across multiple stages, which can result in long-term cost savings and decreased environmental impact through minimized fuel usage. Your choice between CFE and MEE should consider factors such as energy pricing, maintenance expenses, and emissions regulations to optimize both economic and environmental performance.

Choosing the Right Evaporation Method

Choosing the right evaporation method depends on factors like energy efficiency, scalability, and product sensitivity. Continuous flash evaporation offers rapid processing suitable for heat-sensitive materials, minimizing thermal degradation, whereas multiple effect evaporation maximizes energy savings through successive vapor reutilization, making it ideal for large-scale operations. Your decision should consider the specific thermal stability of your product and operational cost constraints to optimize overall performance.

Continuous flash evaporation vs multiple effect evaporation Infographic

libmatt.com

libmatt.com