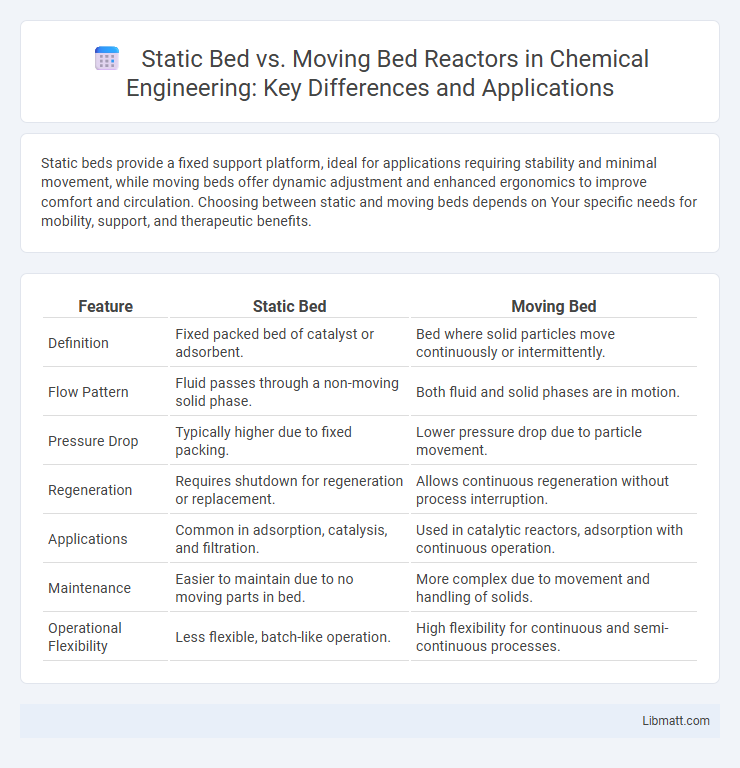

Static beds provide a fixed support platform, ideal for applications requiring stability and minimal movement, while moving beds offer dynamic adjustment and enhanced ergonomics to improve comfort and circulation. Choosing between static and moving beds depends on Your specific needs for mobility, support, and therapeutic benefits.

Table of Comparison

| Feature | Static Bed | Moving Bed |

|---|---|---|

| Definition | Fixed packed bed of catalyst or adsorbent. | Bed where solid particles move continuously or intermittently. |

| Flow Pattern | Fluid passes through a non-moving solid phase. | Both fluid and solid phases are in motion. |

| Pressure Drop | Typically higher due to fixed packing. | Lower pressure drop due to particle movement. |

| Regeneration | Requires shutdown for regeneration or replacement. | Allows continuous regeneration without process interruption. |

| Applications | Common in adsorption, catalysis, and filtration. | Used in catalytic reactors, adsorption with continuous operation. |

| Maintenance | Easier to maintain due to no moving parts in bed. | More complex due to movement and handling of solids. |

| Operational Flexibility | Less flexible, batch-like operation. | High flexibility for continuous and semi-continuous processes. |

Introduction to Static Bed and Moving Bed Technologies

Static bed technology involves fixed, immobile media through which fluids or gases pass for processes like filtration or adsorption, offering simplicity and low maintenance. Moving bed technology uses continuously or intermittently moving particles within a reactor or vessel to enhance mass transfer and reaction efficiency, commonly applied in fluid catalytic cracking and biofilm reactors. These distinctions impact operational dynamics, with static beds favoring stability and moving beds providing improved contact and regeneration capabilities.

Fundamental Principles of Static Bed Operations

Static bed operations rely on a fixed arrangement of particles where fluid flows through the stationary solid matrix, enabling processes such as filtration, adsorption, or catalytic reactions. The fundamental principle involves maintaining a stable, compacted bed to maximize contact efficiency between phases, minimizing channeling and ensuring uniform flow distribution. Key parameters include bed porosity, particle size distribution, and flow rate, which directly influence pressure drop and mass transfer effectiveness.

Key Features of Moving Bed Systems

Moving bed systems feature continuous movement of the solid phase, enhancing mass transfer and contact efficiency between phases. Your operation benefits from improved catalyst regeneration and reduced channeling compared to static beds, resulting in higher process stability and throughput. These systems also enable better temperature control and uniform particle distribution, optimizing reaction performance in industrial applications.

Comparative Efficiency: Static Bed vs Moving Bed

Static beds offer consistent performance with minimal mechanical complexity, ideal for applications requiring steady-state operations and ease of maintenance. Moving beds enhance mass transfer efficiency and reduce channeling by continuously agitating the media, leading to improved reaction rates or separation processes. Your process efficiency can significantly benefit from selecting a moving bed system when higher throughput and enhanced contact between phases are critical.

Application Areas for Static and Moving Beds

Static beds are predominantly used in fixed-bed reactors for catalytic processes, adsorption, and filtration in industries like chemical manufacturing and wastewater treatment. Moving beds find applications in fluid catalytic cracking units, continuous gas-solid reactions, and biomass gasification due to their enhanced heat and mass transfer capabilities. Your choice between static and moving beds depends on process requirements such as reaction dynamics, throughput, and maintenance considerations.

Maintenance and Operational Costs Comparison

Static beds generally require lower maintenance costs due to fewer moving parts and simpler construction, reducing the frequency of repairs and part replacements. Moving beds involve higher operational costs stemming from increased energy consumption to keep the bed in motion and more frequent maintenance due to wear and tear on mechanical components. The choice between static and moving beds significantly impacts long-term maintenance budgets and operational efficiency in industrial applications.

Scalability and Design Flexibility

Static beds offer limited scalability due to their fixed structure and lower adaptability to changing process demands, making them less ideal for rapid capacity expansion. Moving beds provide enhanced design flexibility through continuous operation and easier integration of adaptive control systems, allowing for seamless scaling in industrial processes. These features make moving beds preferable in dynamic environments requiring modular growth and customizable flow patterns.

Environmental Impact and Sustainability

Static beds typically consume less energy and generate minimal emissions compared to moving beds, making them more environmentally sustainable for processes like filtration or biofilm growth. Moving beds offer enhanced efficiency and higher throughput, but their increased mechanical complexity often results in higher energy use and maintenance-related impacts. Selecting between static and moving bed systems requires balancing operational efficiency with ecological footprints to optimize sustainability outcomes.

Challenges and Limitations of Each System

Static bed systems face challenges such as limited mass transfer efficiency and difficulty in maintaining uniform flow distribution, leading to potential channeling and pressure drop issues. Moving bed systems encounter complexities including mechanical wear, higher operational costs, and the need for continuous solids handling, which can complicate system design and maintenance. Both systems require careful consideration of material properties and process conditions to mitigate these limitations and ensure optimal performance.

Choosing the Right Bed Technology for Your Process

Selecting the right bed technology depends on the specific requirements of your process, such as flow rate, particle retention, and regeneration needs. Static beds offer simple design and ease of maintenance but can suffer from channeling and limited mass transfer efficiency, while moving beds provide continuous particle movement that reduces clogging and enhances contact between phases. Understanding the trade-offs between static bed stability and moving bed flexibility ensures optimal performance and operational efficiency for your system.

static bed vs moving bed Infographic

libmatt.com

libmatt.com