Powder metallurgy involves compacting and sintering metal powders to create complex parts with tailored properties, offering cost-effective production for high-strength components. Chemical vapor deposition (CVD) is a process where thin films are deposited onto substrates through chemical reactions of vapor-phase precursors, providing superior surface coatings for enhanced wear resistance and corrosion protection.

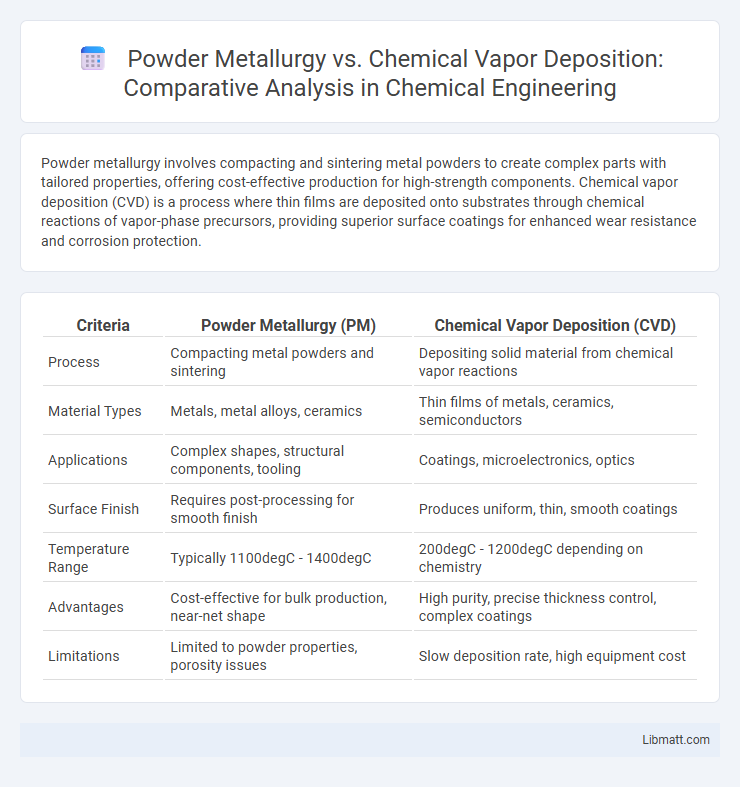

Table of Comparison

| Criteria | Powder Metallurgy (PM) | Chemical Vapor Deposition (CVD) |

|---|---|---|

| Process | Compacting metal powders and sintering | Depositing solid material from chemical vapor reactions |

| Material Types | Metals, metal alloys, ceramics | Thin films of metals, ceramics, semiconductors |

| Applications | Complex shapes, structural components, tooling | Coatings, microelectronics, optics |

| Surface Finish | Requires post-processing for smooth finish | Produces uniform, thin, smooth coatings |

| Temperature Range | Typically 1100degC - 1400degC | 200degC - 1200degC depending on chemistry |

| Advantages | Cost-effective for bulk production, near-net shape | High purity, precise thickness control, complex coatings |

| Limitations | Limited to powder properties, porosity issues | Slow deposition rate, high equipment cost |

Introduction to Powder Metallurgy and Chemical Vapor Deposition

Powder metallurgy involves compacting metal powders and sintering them to create solid metal parts with precise shapes and properties, making it ideal for complex geometries and high-performance components. Chemical vapor deposition (CVD) is a process where gaseous precursors react on a substrate surface to form thin, uniform coatings or films, commonly used in semiconductor manufacturing and protective coatings. Your choice between these manufacturing methods depends on factors such as material properties, thickness requirements, and application-specific performance needs.

Fundamental Principles of Powder Metallurgy

Powder metallurgy involves the production of materials or components from metal powders through processes such as compaction and sintering, enabling precise control over microstructure and properties. This technique relies on the metallurgical bonding of particles at elevated temperatures without melting the entire material, offering advantages in manufacturing complex shapes with minimal waste. Understanding these fundamental principles helps you choose the most suitable method when comparing powder metallurgy to chemical vapor deposition for specific applications.

Core Concepts of Chemical Vapor Deposition

Chemical Vapor Deposition (CVD) involves the chemical reaction of gaseous precursors on a heated substrate to produce a solid material layer with precise control over composition and thickness. This process creates high-purity, dense coatings essential for semiconductor devices, protective barriers, and advanced material fabrication. Compared to powder metallurgy, which compacts metal powders into shapes, CVD excels in thin film deposition with superior uniformity and adhesion.

Materials Processed by Each Technique

Powder metallurgy primarily processes metals and metal alloys such as stainless steel, titanium, and nickel-based superalloys, enabling precise control over composition and microstructure. Chemical vapor deposition (CVD) is used to deposit thin films of materials including silicon, silicon carbide, tungsten, and various oxides or nitrides onto substrates for electronic, optical, and protective applications. Your choice depends on whether bulk material fabrication or surface coating with high purity and uniformity is needed.

Step-by-Step Process Comparison

Powder metallurgy involves compacting metal powders into a desired shape followed by sintering to bond particles at high temperatures without melting. Chemical vapor deposition (CVD) uses chemical reactions of gaseous precursors on a heated substrate to form thin, uniform coatings layer by layer. Your choice depends on whether bulk material fabrication or precise thin-film deposition suits your application needs.

Key Applications in Industry

Powder metallurgy is extensively used in automotive manufacturing for producing gears, bearings, and other high-strength components with precise shapes and minimal waste. Chemical vapor deposition (CVD) plays a crucial role in the semiconductor industry, enabling the fabrication of thin films and coatings for microelectronics and solar panels. Your choice between these methods depends on required material properties and application, where powder metallurgy suits bulk metal parts and CVD excels in advanced surface engineering.

Advantages of Powder Metallurgy

Powder metallurgy offers advantages such as cost-effective production of complex shapes with minimal material waste, improved material utilization, and enhanced mechanical properties through controlled powder composition and sintering processes. This technique enables precise control over porosity and microstructure, resulting in components with superior wear resistance and high strength-to-weight ratios. Compared to chemical vapor deposition, powder metallurgy allows for bulk material fabrication with scalable production and reduced energy consumption.

Benefits of Chemical Vapor Deposition

Chemical Vapor Deposition (CVD) offers superior coating uniformity and excellent control over film composition compared to powder metallurgy, enabling the production of ultra-thin, high-purity coatings essential for semiconductor and optics applications. CVD processes also facilitate the deposition of materials at the atomic level, resulting in enhanced mechanical properties, corrosion resistance, and thermal stability. Your components benefit from improved surface quality and tailored material properties, which are difficult to achieve with traditional powder metallurgy techniques.

Limitations and Challenges of Both Methods

Powder metallurgy faces challenges such as limited part geometries, potential porosity, and difficulty achieving complex shapes with fine tolerances. Chemical vapor deposition encounters limitations including high operational costs, complex equipment requirements, and difficulty controlling uniform thickness on intricate surfaces. Both methods struggle with material contamination risks and scalability for mass production.

Choosing the Right Technique: Factors to Consider

When choosing between powder metallurgy and chemical vapor deposition, consider factors such as material properties, desired microstructure, and production volume. Powder metallurgy is ideal for manufacturing complex, high-strength metal parts with precise control over composition and porosity, especially for large-scale production. Your choice should also weigh the temperature sensitivity of the components and coating thickness requirements, as chemical vapor deposition excels in delivering uniform, high-purity coatings on intricate surfaces at a micro- to nanoscale level.

powder metallurgy vs chemical vapor deposition Infographic

libmatt.com

libmatt.com