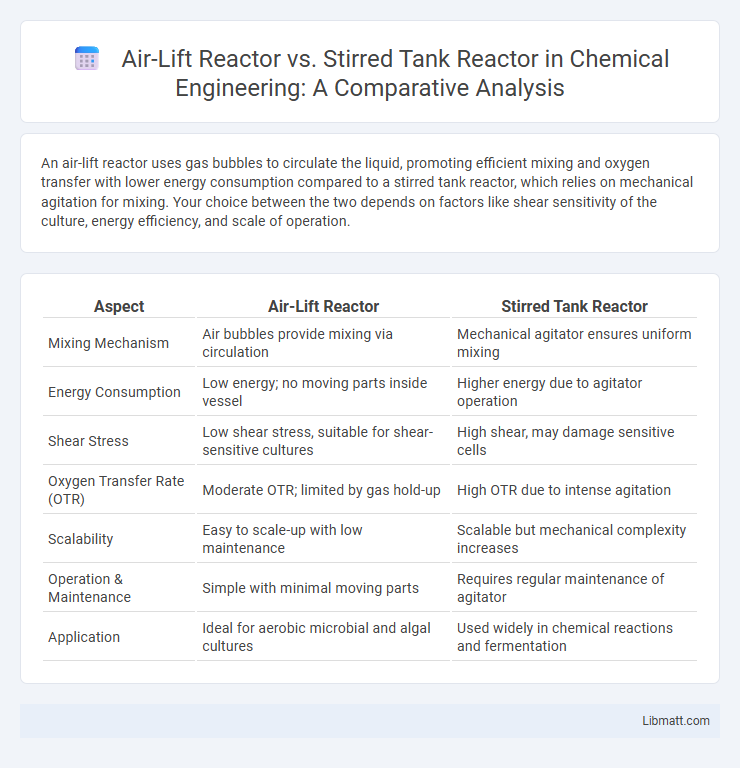

An air-lift reactor uses gas bubbles to circulate the liquid, promoting efficient mixing and oxygen transfer with lower energy consumption compared to a stirred tank reactor, which relies on mechanical agitation for mixing. Your choice between the two depends on factors like shear sensitivity of the culture, energy efficiency, and scale of operation.

Table of Comparison

| Aspect | Air-Lift Reactor | Stirred Tank Reactor |

|---|---|---|

| Mixing Mechanism | Air bubbles provide mixing via circulation | Mechanical agitator ensures uniform mixing |

| Energy Consumption | Low energy; no moving parts inside vessel | Higher energy due to agitator operation |

| Shear Stress | Low shear stress, suitable for shear-sensitive cultures | High shear, may damage sensitive cells |

| Oxygen Transfer Rate (OTR) | Moderate OTR; limited by gas hold-up | High OTR due to intense agitation |

| Scalability | Easy to scale-up with low maintenance | Scalable but mechanical complexity increases |

| Operation & Maintenance | Simple with minimal moving parts | Requires regular maintenance of agitator |

| Application | Ideal for aerobic microbial and algal cultures | Used widely in chemical reactions and fermentation |

Introduction to Air-lift and Stirred Tank Reactors

Air-lift reactors use gas injection to circulate liquid and particles, creating efficient mixing with low shear forces ideal for sensitive biological cultures. Stirred tank reactors rely on mechanical agitation via impellers, offering precise control over mixing intensity and oxygen transfer rates suitable for diverse chemical and biochemical processes. Your choice depends on the balance between gentle mixing in air-lift systems and the robust agitation capabilities of stirred tank reactors.

Fundamental Principles of Reactor Design

Air-lift reactors utilize gas injection to create circulating fluid motion, enhancing mass transfer and mixing with low shear stress, making them ideal for shear-sensitive biological processes. In contrast, stirred tank reactors rely on mechanical agitation through impellers to achieve uniform mixing and maintain controlled reaction conditions, suitable for a wide range of chemical reactions. The choice between air-lift and stirred tank reactors depends on factors like energy efficiency, mixing intensity, and the sensitivity of the biological or chemical system involved.

Mechanisms of Mixing and Mass Transfer

Air-lift reactors utilize gas bubbles to create a circulating flow pattern, enhancing mixing and mass transfer by minimizing shear stress and promoting efficient gas-liquid contact. Stirred tank reactors rely on mechanical agitation with impellers, generating turbulent flow that improves mixing intensity and mass transfer rates but may cause higher shear stress, potentially damaging sensitive materials. Your choice depends on the desired balance between efficient mass transfer and gentle mixing conditions suitable for your process.

Energy Efficiency and Power Consumption

Air-lift reactors exhibit higher energy efficiency due to their enhanced gas-liquid mass transfer and reduced mechanical agitation requirements, resulting in lower power consumption compared to stirred tank reactors. Stirred tank reactors rely on impellers for mixing, which typically consume more energy to achieve uniform suspension and oxygen transfer. The absence of mechanical stirring in air-lift reactors minimizes shear stress and operational costs, making them more suitable for processes demanding energy-efficient bioreactor designs.

Scalability and Industrial Applications

Air-lift reactors offer superior scalability due to their simple design and low shear environment, making them ideal for large-scale bioprocesses such as wastewater treatment and fermentation industries. Stirred tank reactors provide enhanced mixing and precise control over reaction parameters, which is beneficial in pharmaceutical manufacturing and enzyme production. The choice between air-lift and stirred tank reactors depends on the specific industrial application demands, with air-lift reactors favoring energy efficiency and scalability, while stirred tanks excel in versatile process control.

Oxygen Transfer Rates and Gas-Liquid Interactions

Air-lift reactors provide higher oxygen transfer rates due to enhanced gas-liquid mixing and lower shear stress compared to stirred tank reactors, which rely on mechanical agitation for oxygen dispersion. The hydrodynamics in air-lift reactors promote efficient gas holdup and bubble coalescence control, improving gas-liquid mass transfer coefficients (kLa). Stirred tank reactors exhibit more turbulent flow, resulting in variable oxygen transfer efficiency and potentially increased cell damage in bioprocess applications.

Shear Stress Impact on Cell Viability

Air-lift reactors generate lower shear stress compared to stirred tank reactors, making them more suitable for shear-sensitive cell cultures. The gentle circulation in air-lift reactors preserves cell viability by minimizing mechanical damage, whereas stirred tank reactors use impellers that can create high shear forces harmful to delicate cells. Your choice of reactor significantly influences cell survival rates, especially in processes involving fragile mammalian or microbial cells.

Maintenance, Cost, and Operational Considerations

Air-lift reactors require lower maintenance due to fewer moving parts and reduced mechanical wear compared to stirred tank reactors, which involve frequent inspection of agitators and seals. The initial cost of air-lift reactors is generally lower because of simpler design and energy-efficient operation, while stirred tank reactors often incur higher energy and maintenance expenses. Operationally, air-lift reactors provide gentle mixing suited for shear-sensitive processes and easier scale-up, whereas stirred tank reactors offer precise control over mixing intensity but demand higher maintenance efforts.

Comparative Performance in Bioprocesses

Air-lift reactors exhibit superior oxygen transfer rates and reduced shear stress compared to stirred tank reactors, enhancing microbial and cell culture growth in bioprocesses. Stirred tank reactors offer precise mixing and control over temperature, pH, and nutrient distribution, making them suitable for highly sensitive fermentation processes. The choice between air-lift and stirred tank reactors depends on specific bioprocess requirements such as oxygen demand, shear sensitivity, and scalability.

Conclusion: Choosing the Optimal Reactor System

Air-lift reactors offer superior mixing and gas transfer efficiency with lower shear stress, making them ideal for delicate biological processes and large-scale aerobic fermentations. Stirred tank reactors provide enhanced control over reaction parameters and are preferred for highly viscous fluids or processes requiring precise agitation. Selecting the optimal reactor depends on the specific application requirements, such as gas-liquid mass transfer, shear sensitivity, scale, and ease of operation.

Air-lift reactor vs stirred tank reactor Infographic

libmatt.com

libmatt.com