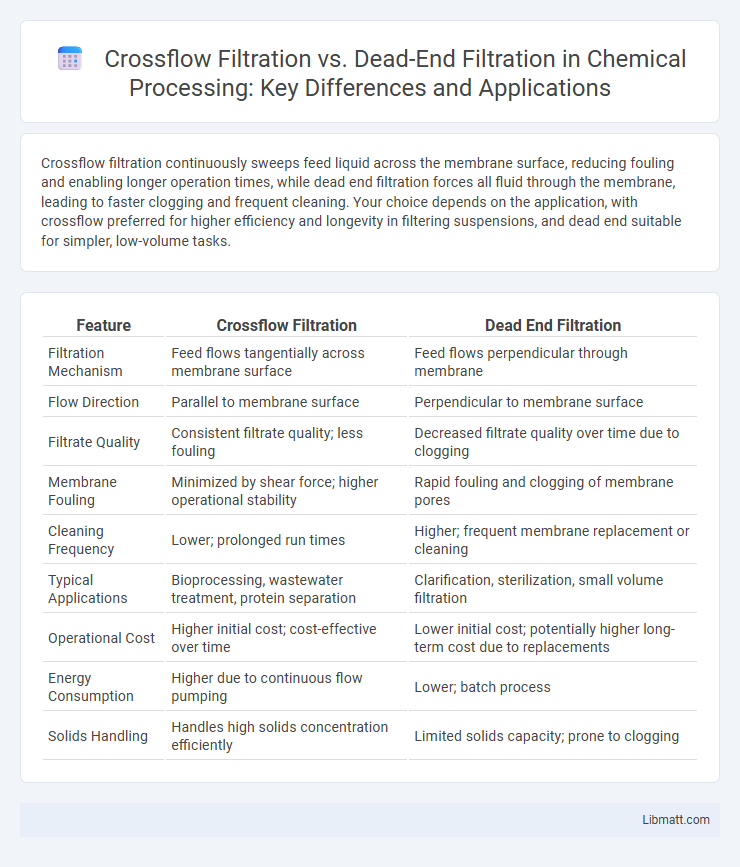

Crossflow filtration continuously sweeps feed liquid across the membrane surface, reducing fouling and enabling longer operation times, while dead end filtration forces all fluid through the membrane, leading to faster clogging and frequent cleaning. Your choice depends on the application, with crossflow preferred for higher efficiency and longevity in filtering suspensions, and dead end suitable for simpler, low-volume tasks.

Table of Comparison

| Feature | Crossflow Filtration | Dead End Filtration |

|---|---|---|

| Filtration Mechanism | Feed flows tangentially across membrane surface | Feed flows perpendicular through membrane |

| Flow Direction | Parallel to membrane surface | Perpendicular to membrane surface |

| Filtrate Quality | Consistent filtrate quality; less fouling | Decreased filtrate quality over time due to clogging |

| Membrane Fouling | Minimized by shear force; higher operational stability | Rapid fouling and clogging of membrane pores |

| Cleaning Frequency | Lower; prolonged run times | Higher; frequent membrane replacement or cleaning |

| Typical Applications | Bioprocessing, wastewater treatment, protein separation | Clarification, sterilization, small volume filtration |

| Operational Cost | Higher initial cost; cost-effective over time | Lower initial cost; potentially higher long-term cost due to replacements |

| Energy Consumption | Higher due to continuous flow pumping | Lower; batch process |

| Solids Handling | Handles high solids concentration efficiently | Limited solids capacity; prone to clogging |

Introduction to Filtration Techniques

Crossflow filtration uses a tangential flow to continuously sweep the filter membrane, reducing clogging and enabling efficient separation of particles from liquids, making it ideal for processing large volumes or dealing with fouling-prone feeds. Dead end filtration forces the entire feed stream perpendicular to the membrane, causing particles to accumulate on the surface, which often leads to faster membrane fouling and requires frequent cleaning or replacement. These techniques differ significantly in operational efficiency, membrane longevity, and application suitability in industries such as biotechnology, water treatment, and food processing.

What is Crossflow Filtration?

Crossflow filtration is a separation process where feed solution flows tangentially across the membrane surface, reducing fouling and allowing continuous filtration. This method maintains a constant feed flow, pushing unwanted particles and solutes along the membrane to be removed, enhancing filtration efficiency and membrane lifespan. Compared to dead end filtration, crossflow filtration offers higher flux rates and improved handling of feed with high solids content.

What is Dead End Filtration?

Dead End Filtration is a process where the feed stream passes perpendicularly through the filter media, causing particles to accumulate on the surface and form a filter cake. This method is efficient for separating solids from liquids in batch operations but often requires frequent cleaning or replacement due to clogging. Understanding this filtration type helps you select the appropriate system for applications with low particle loads or where simplicity is essential.

Key Differences Between Crossflow and Dead End Filtration

Crossflow filtration continuously moves the feed fluid tangentially across the filter membrane, reducing clogging and allowing for prolonged filtration cycles, while dead end filtration forces all feed fluid directly through the membrane, leading to faster buildup of solids and frequent cleaning. Crossflow filtration offers higher efficiency in separating particles and maintaining flux rates, whereas dead end filtration is simpler and often used for batch processes with lower suspension concentrations. Your choice between these methods depends on factors such as feed composition, desired throughput, and maintenance frequency.

Advantages of Crossflow Filtration

Crossflow filtration offers significant advantages such as continuous operation without frequent filter clogging, leading to higher efficiency in separating suspended solids from liquids. It maintains a steady filtrate flux by sweeping away particles from the membrane surface, reducing fouling and extending membrane lifespan. This method is particularly beneficial in applications requiring consistent filtration performance and lower maintenance costs compared to dead end filtration.

Advantages of Dead End Filtration

Dead end filtration offers advantages such as simplicity in design and operation, lower equipment costs, and reduced maintenance requirements compared to crossflow filtration. It is highly effective in applications where the feed contains low solids concentrations, enabling efficient particle removal through a single pass. Its straightforward setup makes it ideal for small-scale or batch filtration processes where process control and cost-effectiveness are prioritized.

Limitations of Crossflow Filtration

Crossflow filtration faces limitations such as higher energy consumption due to continuous tangential flow and increased operational complexity compared to dead-end filtration. Membrane fouling remains a challenge, requiring frequent cleaning protocols to maintain efficiency. The initial setup and maintenance costs are generally higher, making it less suitable for applications requiring low operational budgets.

Limitations of Dead End Filtration

Dead end filtration faces significant limitations such as rapid membrane fouling due to particle accumulation on the filter surface, leading to frequent clogging and decreased filtration efficiency. This method requires higher maintenance and cleaning cycles, increasing operational downtime and costs. Flow disruptions in dead end filtration compromise the consistency of filtration, making it less suitable for processes demanding continuous or high-volume throughput compared to crossflow filtration.

Common Applications: Crossflow vs Dead End Filtration

Crossflow filtration is commonly used in applications requiring continuous separation of solids from liquids, such as wastewater treatment, protein purification, and dairy processing, due to its efficiency in handling high-solids content and minimizing membrane fouling. Dead end filtration is typically preferred for straightforward processes like air filtration or sample clarification where simplicity and lower operational costs matter more than filter longevity. Understanding the specific requirements of your filtration process helps determine whether crossflow or dead end filtration offers the optimal balance of performance and maintenance.

Choosing the Right Filtration Method for Your Process

Crossflow filtration enhances separation efficiency by continuously sweeping away filtered particles, reducing membrane fouling and enabling longer operation times compared to dead-end filtration, which traps particles on the membrane surface, causing faster clogging and shorter cycles. Your choice depends on factors like feed solution composition, desired throughput, and cleaning frequency; crossflow suits high-solids fluids and processes requiring prolonged filtration, while dead-end is cost-effective for low-solids or batch applications. Understanding the operational demands and maintenance constraints of each method ensures optimal performance and cost-efficiency in your filtration process.

Crossflow filtration vs dead end filtration Infographic

libmatt.com

libmatt.com