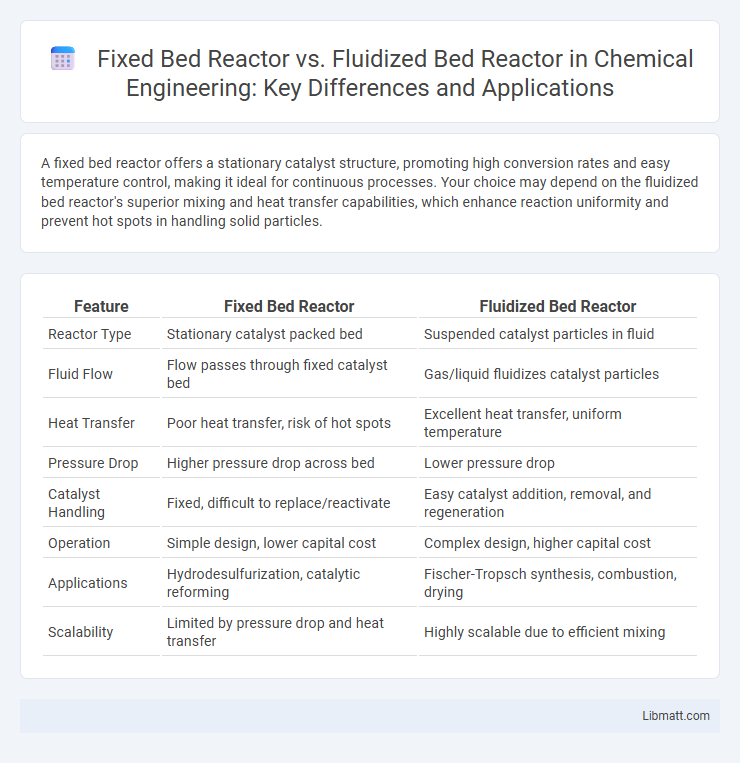

A fixed bed reactor offers a stationary catalyst structure, promoting high conversion rates and easy temperature control, making it ideal for continuous processes. Your choice may depend on the fluidized bed reactor's superior mixing and heat transfer capabilities, which enhance reaction uniformity and prevent hot spots in handling solid particles.

Table of Comparison

| Feature | Fixed Bed Reactor | Fluidized Bed Reactor |

|---|---|---|

| Reactor Type | Stationary catalyst packed bed | Suspended catalyst particles in fluid |

| Fluid Flow | Flow passes through fixed catalyst bed | Gas/liquid fluidizes catalyst particles |

| Heat Transfer | Poor heat transfer, risk of hot spots | Excellent heat transfer, uniform temperature |

| Pressure Drop | Higher pressure drop across bed | Lower pressure drop |

| Catalyst Handling | Fixed, difficult to replace/reactivate | Easy catalyst addition, removal, and regeneration |

| Operation | Simple design, lower capital cost | Complex design, higher capital cost |

| Applications | Hydrodesulfurization, catalytic reforming | Fischer-Tropsch synthesis, combustion, drying |

| Scalability | Limited by pressure drop and heat transfer | Highly scalable due to efficient mixing |

Introduction to Fixed Bed and Fluidized Bed Reactors

Fixed bed reactors contain a stationary packed bed of catalyst or solid particles through which reactants flow, offering high catalyst contact time and simplicity in design. Fluidized bed reactors suspend catalyst particles in an upward-flowing gas or liquid, enhancing heat and mass transfer due to improved mixing and uniform temperature distribution. The choice between fixed and fluidized bed reactors depends on factors like reaction kinetics, heat management, and catalyst regeneration requirements.

Core Principles of Fixed Bed Reactors

Fixed bed reactors operate by passing reactants through a stationary packed bed of catalyst particles, ensuring consistent contact and controlled reaction environments ideal for gas-solid or liquid-solid processes. These reactors provide high mechanical stability, low catalyst attrition, and precise temperature control due to the fixed arrangement of catalyst pellets. Their core principle emphasizes maintaining a uniform flow distribution and minimizing channeling to optimize reaction efficiency and catalyst utilization.

Fundamental Operation of Fluidized Bed Reactors

Fluidized bed reactors operate by suspending solid catalyst particles within an upward flow of gas or liquid, creating a fluid-like state that enhances mass and heat transfer rates. This fundamental operation enables uniform temperature distribution and prevents hot spots, improving reaction efficiency compared to fixed bed reactors where gases flow through static catalyst beds. The dynamic mixing in fluidized beds also allows better control of reaction kinetics and rapid catalyst regeneration.

Key Design Differences

Fixed bed reactors feature a stationary packed catalyst or solid phase, allowing gases or liquids to flow through the immobile bed, which simplifies construction and enhances heat management precision. Fluidized bed reactors operate with solid catalyst particles suspended by upward fluid flow, promoting excellent mixing, uniform temperature distribution, and efficient mass transfer. Key design differences include catalyst movement, heat transfer mechanisms, pressure drop characteristics, and scalability, with fixed beds favoring simplicity and fluidized beds enabling higher throughput and better temperature control.

Advantages of Fixed Bed Reactors

Fixed bed reactors offer advantages such as simpler design, higher catalyst utilization, and lower operational costs compared to fluidized bed reactors. Their fixed catalyst arrangement provides uniform temperature control and minimizes catalyst attrition, enhancing catalyst lifespan and process stability. These reactors are particularly effective for processes requiring precise reaction conditions and ease of scale-up.

Advantages of Fluidized Bed Reactors

Fluidized bed reactors offer superior heat and mass transfer rates compared to fixed bed reactors, enhancing reaction efficiency and temperature control. Their ability to handle large-scale operations with uniform particle mixing reduces hotspots and improves catalyst utilization. You benefit from easier catalyst replacement and scalability, making fluidized bed reactors ideal for processes requiring continuous operation and high throughput.

Limitations and Challenges

Fixed bed reactors face limitations such as channeling, pressure drop increase, and poor heat transfer, which hinder uniform reactant distribution and temperature control. Fluidized bed reactors encounter challenges including particle attrition, complex hydrodynamics, and difficulty in scaling up due to gas-solid interactions. Both reactor types require careful design to mitigate operational issues and optimize performance in industrial applications.

Typical Industrial Applications

Fixed bed reactors are commonly used in industrial applications such as catalytic hydrogenation, hydrodesulfurization, and ammonia synthesis due to their simple design and effective catalyst contact. Fluidized bed reactors find widespread use in processes requiring excellent heat and mass transfer, including fluid catalytic cracking, coal gasification, and combustion in power plants. Your choice depends on process requirements like catalyst handling, reaction uniformity, and operational flexibility.

Energy Efficiency and Performance Comparison

Fixed bed reactors offer higher energy efficiency due to minimal heat loss and better temperature control, making them ideal for processes requiring precise thermal management. Fluidized bed reactors provide superior mixing and mass transfer, enhancing reaction rates and uniformity but often at the cost of increased energy consumption due to gas or fluid circulation. Your choice between these reactors impacts overall process performance, balancing energy efficiency with operational flexibility and throughput.

Choosing the Right Reactor for Your Process

Selecting the ideal reactor depends on specific process requirements such as reaction kinetics, heat transfer efficiency, and catalyst type. Fixed bed reactors provide excellent catalyst stability and straightforward maintenance, making them suitable for slower reactions with solid catalysts. Fluidized bed reactors offer superior heat transfer and uniform temperature distribution, ideal for fast, highly exothermic reactions requiring efficient catalyst regeneration and uniform mixing.

Fixed bed reactor vs fluidized bed reactor Infographic

libmatt.com

libmatt.com