A vacuum pump creates a low-pressure environment by removing gas molecules, ideal for applications requiring suction or vacuum conditions, while a compressor increases gas pressure by compressing air or gases for use in pneumatic tools and systems. Understanding the differences helps you choose the right equipment based on whether you need to generate negative pressure or boost air pressure.

Table of Comparison

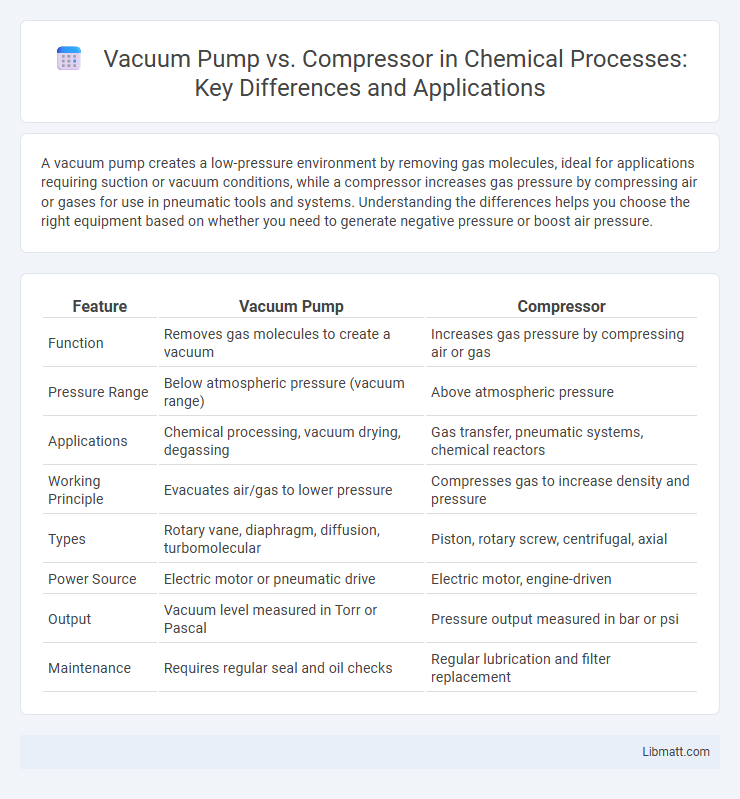

| Feature | Vacuum Pump | Compressor |

|---|---|---|

| Function | Removes gas molecules to create a vacuum | Increases gas pressure by compressing air or gas |

| Pressure Range | Below atmospheric pressure (vacuum range) | Above atmospheric pressure |

| Applications | Chemical processing, vacuum drying, degassing | Gas transfer, pneumatic systems, chemical reactors |

| Working Principle | Evacuates air/gas to lower pressure | Compresses gas to increase density and pressure |

| Types | Rotary vane, diaphragm, diffusion, turbomolecular | Piston, rotary screw, centrifugal, axial |

| Power Source | Electric motor or pneumatic drive | Electric motor, engine-driven |

| Output | Vacuum level measured in Torr or Pascal | Pressure output measured in bar or psi |

| Maintenance | Requires regular seal and oil checks | Regular lubrication and filter replacement |

Understanding Vacuum Pumps and Compressors

Vacuum pumps and compressors both manipulate gas pressure but serve distinct purposes; vacuum pumps reduce pressure to create a vacuum, while compressors increase pressure to move or store gases. Vacuum pumps are essential in industries like semiconductor manufacturing and scientific research, where precise low-pressure environments are required. Compressors play a critical role in HVAC systems, pneumatic tools, and refrigeration by compressing air or gas to higher pressures for operational efficiency.

Key Differences Between Vacuum Pumps and Compressors

Vacuum pumps and compressors differ primarily in their function: vacuum pumps remove air or gas molecules to create a low-pressure environment, while compressors increase the pressure of gases by reducing their volume. Vacuum pumps are essential in applications requiring a vacuum, such as semiconductor manufacturing or laboratory processes, whereas compressors are crucial in industries like refrigeration, pneumatic tools, and HVAC systems. Your choice between the two depends on whether you need to evacuate air or compress it for specific industrial or scientific uses.

How Do Vacuum Pumps Work?

Vacuum pumps operate by removing gas molecules from a sealed volume to create a partial vacuum, lowering the pressure inside the chamber below atmospheric levels. These pumps utilize mechanisms such as rotary vanes, diaphragm motion, or piston action to move air or gas out, enabling applications in scientific research, manufacturing, and medical devices. Unlike compressors, which pressurize air or gases by increasing their pressure, vacuum pumps focus on gas extraction to achieve low-pressure environments.

How Do Compressors Operate?

Compressors operate by increasing the pressure of a gas by reducing its volume, typically through mechanical means such as pistons, rotary screws, or centrifugal force. Unlike vacuum pumps that remove air or gas to create a pressure lower than atmospheric pressure, compressors take in gas at atmospheric pressure and output it at a higher pressure. Your choice between a vacuum pump and a compressor depends on whether you need to create a vacuum or pressurize a gas for your application.

Common Applications of Vacuum Pumps

Vacuum pumps are commonly used in industries such as pharmaceuticals for freeze-drying and packaging, semiconductor manufacturing for creating controlled environments, and automotive sectors for brake systems and fuel evaporation control. They are integral in laboratory settings for distillation, filtration, and vacuum drying processes. Their ability to remove gas molecules from sealed volumes distinguishes them from compressors, which typically increase gas pressure.

Typical Uses of Compressors

Compressors are commonly used in industrial applications such as powering pneumatic tools, refrigeration systems, and air conditioning units. They deliver pressurized air or gas essential for manufacturing processes, HVAC systems, and automotive service equipment. Your choice of compressor will depend on the required pressure, volume, and efficiency for specific operations.

Performance Comparison: Efficiency and Output

Vacuum pumps excel in creating low-pressure environments by removing gas molecules, achieving high vacuum levels with efficiencies typically measured by ultimate pressure and pumping speed, while compressors increase gas pressure by reducing volume, focusing on flow rate and pressure ratio for performance. Efficiency in vacuum pumps is often determined by their ability to maintain consistent low pressures with minimal energy consumption, whereas compressors prioritize maximizing pressure output and volumetric efficiency to deliver higher flow rates. Output differences highlight vacuum pumps' specialization in achieving near-zero absolute pressures essential for scientific and industrial applications, contrasted with compressors' capability to produce high-pressure air or gas streams critical for pneumatic systems and HVAC performance.

Maintenance and Longevity Considerations

Vacuum pumps typically require regular oil changes and seal inspections to maintain optimal performance and extend service life, with dry pumps demanding simpler upkeep but higher wear rates. Compressors often need frequent filter replacements, lubrication checks, and pressure valve maintenance to prevent overheating and ensure durability under high-pressure operation. Proper maintenance schedules and high-quality components significantly enhance the longevity of both devices, reducing downtime and operational costs in industrial applications.

Choosing the Right Device for Your Needs

Selecting between a vacuum pump and a compressor depends on the application's pressure requirements and medium handling. Vacuum pumps are essential for creating low-pressure environments by removing air or gas, ideal for processes like degassing or maintaining vacuum chambers. Compressors increase air or gas pressure, suitable for tasks such as pneumatic tools operation or refrigeration systems, making the choice crucial based on whether suction or pressurization is needed.

Cost Analysis: Vacuum Pump vs Compressor

Vacuum pumps generally have a higher initial cost compared to compressors due to their specialized components and precise engineering, but they often incur lower operational expenses in applications requiring low-pressure environments. Compressors usually exhibit lower upfront investment and maintenance costs, making them more cost-effective for high-pressure air or gas delivery tasks. Your choice should weigh long-term energy consumption and maintenance needs against initial purchase price to determine overall cost efficiency.

Vacuum pump vs compressor Infographic

libmatt.com

libmatt.com