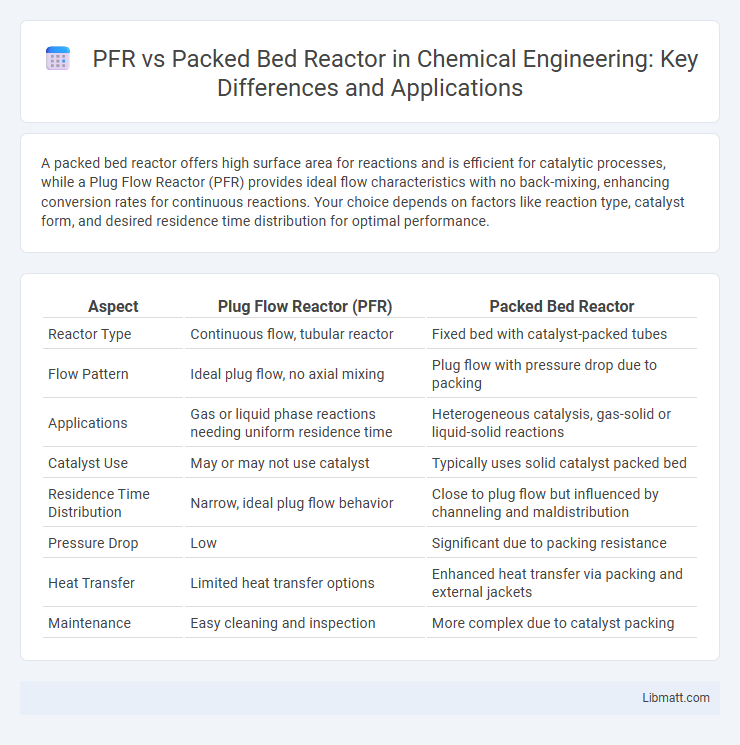

A packed bed reactor offers high surface area for reactions and is efficient for catalytic processes, while a Plug Flow Reactor (PFR) provides ideal flow characteristics with no back-mixing, enhancing conversion rates for continuous reactions. Your choice depends on factors like reaction type, catalyst form, and desired residence time distribution for optimal performance.

Table of Comparison

| Aspect | Plug Flow Reactor (PFR) | Packed Bed Reactor |

|---|---|---|

| Reactor Type | Continuous flow, tubular reactor | Fixed bed with catalyst-packed tubes |

| Flow Pattern | Ideal plug flow, no axial mixing | Plug flow with pressure drop due to packing |

| Applications | Gas or liquid phase reactions needing uniform residence time | Heterogeneous catalysis, gas-solid or liquid-solid reactions |

| Catalyst Use | May or may not use catalyst | Typically uses solid catalyst packed bed |

| Residence Time Distribution | Narrow, ideal plug flow behavior | Close to plug flow but influenced by channeling and maldistribution |

| Pressure Drop | Low | Significant due to packing resistance |

| Heat Transfer | Limited heat transfer options | Enhanced heat transfer via packing and external jackets |

| Maintenance | Easy cleaning and inspection | More complex due to catalyst packing |

Introduction to PFR and Packed Bed Reactor

Plug Flow Reactors (PFR) are tubular reactors where reactants flow continuously in one direction with no back-mixing, ensuring uniform residence time and high conversion efficiency. Packed Bed Reactors consist of a vessel filled with solid catalyst particles, where fluid phase reactants pass through the packed bed, facilitating heterogeneous catalytic reactions. Both reactor types are widely used in chemical and petrochemical industries for processes requiring precise control over reaction kinetics and heat transfer.

Basic Principles of PFR (Plug Flow Reactor)

A Plug Flow Reactor (PFR) operates on the principle that reactants flow through a cylindrical pipe as a "plug," maintaining a uniform velocity profile and no axial mixing, allowing high conversion efficiency in continuous flow processes. The concentration and temperature gradients develop along the reactor length, optimizing reaction progression and heat transfer. Understanding your system's reaction kinetics and flow behavior is essential for leveraging PFR advantages over packed bed reactors in catalytic or homogeneous reactions.

Fundamentals of Packed Bed Reactors

Packed bed reactors (PBRs) consist of a fixed bed of solid catalyst particles through which reactant fluids flow, enabling surface catalytic reactions under continuous operation. You benefit from high catalyst surface area and ease of temperature control due to the packed configuration, which promotes efficient mass and heat transfer while minimizing channeling and pressure drop. Understanding fluid dynamics, catalyst distribution, and reaction kinetics is fundamental to optimizing PBR performance and scale-up in chemical processing applications.

Design and Construction Differences

Packed bed reactors feature a fixed bed of solid catalyst particles through which reactants flow, requiring careful design to ensure uniform flow distribution and minimize pressure drop. Plug flow reactors (PFRs) consist of tubular reactors where reactants move in one direction with no back-mixing, designed to maintain ideal plug flow characteristics by controlling reactor length and diameter. Your choice between a PFR and packed bed reactor influences construction materials and design complexity based on factors like heat transfer efficiency, catalyst handling, and operational pressure.

Flow Patterns and Mixing Characteristics

Plug Flow Reactors (PFR) exhibit a unidirectional flow pattern with minimal axial mixing, ensuring that fluid elements move through the reactor in a plug-like fashion, which enhances conversion efficiency in reactions sensitive to residence time distribution. Packed bed reactors, filled with catalyst particles, induce complex flow patterns including channeling and stagnant zones that can reduce effective mixing and cause non-uniform contact between reactants and catalyst surfaces. Understanding these flow and mixing characteristics is crucial for optimizing your reactor design to maximize reaction rates and selectivity.

Heat and Mass Transfer Comparison

Packed bed reactors exhibit superior heat transfer efficiency due to the intimate contact between the solid catalyst particles and the reactant fluids, enabling effective thermal management and minimizing hotspots. Plug flow reactors (PFRs) typically rely on convective heat transfer along the reactor length, which can result in less uniform temperature profiles and potential thermal gradients detrimental to reaction selectivity. Mass transfer in packed bed reactors benefits from enhanced surface area and turbulence induced by the packing, improving reactant diffusion rates compared to the predominantly axial flow and limited radial mixing observed in PFRs.

Operational Advantages and Limitations

Plug Flow Reactors (PFR) offer high conversion efficiency due to ideal plug flow behavior, enabling uniform reaction conditions and better temperature control, which is beneficial for your continuous production processes. Packed bed reactors provide excellent catalyst support and high surface area for heterogeneous reactions but may face issues with pressure drop and channeling that impact operational stability. While PFRs suit fast, homogeneous reactions with minimal back-mixing, packed bed reactors excel in handling solid catalysts but require careful management of flow distribution and heat removal.

Common Applications in Industry

Plug Flow Reactors (PFR) are commonly used in large-scale continuous chemical processes such as polymerization, oxidation, and nitration reactions due to their efficient handling of high flow rates and uniform residence time distribution. Packed bed reactors excel in catalytic processes like hydrogenation, hydrocracking, and reforming, where catalysts are immobilized on solid supports to enhance reaction rates. Selecting between PFR and packed bed reactors depends on your process requirements, including reaction kinetics, catalyst type, and scalability.

Catalyst Use and Management

Packed bed reactors (PBRs) offer superior catalyst utilization due to the fixed arrangement of catalyst pellets, enabling consistent contact with reactants and minimizing catalyst attrition. In contrast, plug flow reactors (PFRs) typically use catalysts suspended or coated within the reactor, which can lead to uneven catalyst distribution and challenges in catalyst replacement or regeneration. Catalyst management in PBRs simplifies monitoring and maintenance, while PFRs require more complex strategies to maintain catalyst efficacy over time.

Selection Criteria: PFR vs Packed Bed Reactor

Selection criteria for choosing between a Plug Flow Reactor (PFR) and a packed bed reactor hinge on factors such as reaction kinetics, phase of reactants, and pressure drop considerations. PFRs are preferred for gas-phase reactions with fast kinetics requiring high conversion per pass, offering uniform concentration gradients and minimized back-mixing. Packed bed reactors excel in heterogeneous catalytic processes involving solid catalysts, providing efficient contact between phases and superior heat management in exothermic reactions.

PFR vs packed bed reactor Infographic

libmatt.com

libmatt.com