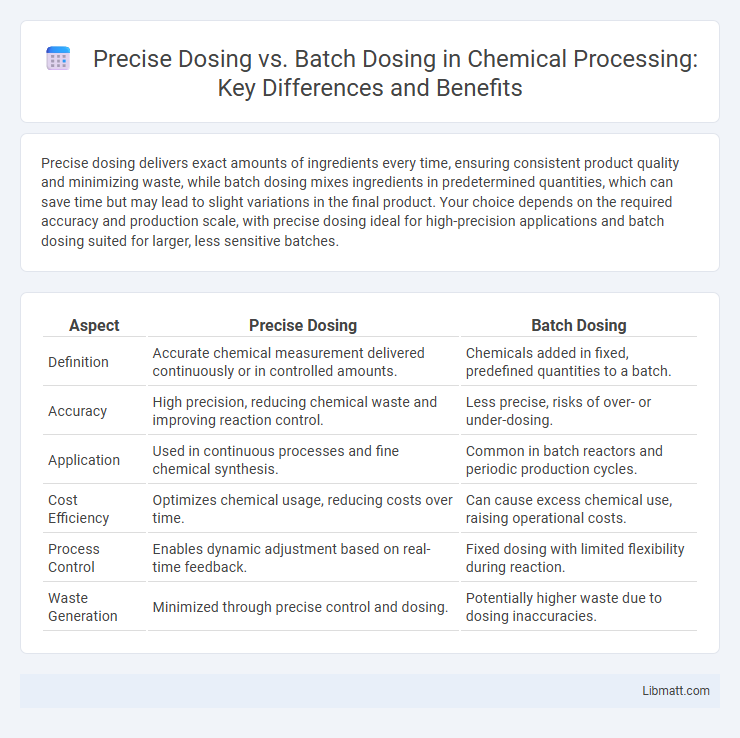

Precise dosing delivers exact amounts of ingredients every time, ensuring consistent product quality and minimizing waste, while batch dosing mixes ingredients in predetermined quantities, which can save time but may lead to slight variations in the final product. Your choice depends on the required accuracy and production scale, with precise dosing ideal for high-precision applications and batch dosing suited for larger, less sensitive batches.

Table of Comparison

| Aspect | Precise Dosing | Batch Dosing |

|---|---|---|

| Definition | Accurate chemical measurement delivered continuously or in controlled amounts. | Chemicals added in fixed, predefined quantities to a batch. |

| Accuracy | High precision, reducing chemical waste and improving reaction control. | Less precise, risks of over- or under-dosing. |

| Application | Used in continuous processes and fine chemical synthesis. | Common in batch reactors and periodic production cycles. |

| Cost Efficiency | Optimizes chemical usage, reducing costs over time. | Can cause excess chemical use, raising operational costs. |

| Process Control | Enables dynamic adjustment based on real-time feedback. | Fixed dosing with limited flexibility during reaction. |

| Waste Generation | Minimized through precise control and dosing. | Potentially higher waste due to dosing inaccuracies. |

Understanding Precise Dosing and Batch Dosing

Precise dosing delivers exact amounts of ingredients, ensuring consistency and minimizing waste in pharmaceutical and food production processes. Batch dosing involves measuring and mixing ingredients in large quantities simultaneously, which can lead to variability between batches but allows for high-volume production. Understanding the distinction helps optimize manufacturing efficiency and product quality control depending on the production scale and application requirements.

Key Differences Between Precise and Batch Dosing

Precise dosing delivers exact amounts of ingredients individually, ensuring consistent product quality and minimizing material waste, while batch dosing mixes all components at once, facilitating faster production but with less accuracy. Precise dosing systems use advanced technology like gravimetric or volumetric dispensers for real-time measurement, whereas batch dosing relies on pre-weighed ingredient batches combined manually or mechanically. These key differences impact production efficiency, cost, and product uniformity across industries such as pharmaceuticals, food processing, and chemical manufacturing.

Advantages of Precise Dosing

Precise dosing offers enhanced accuracy by delivering exact medication quantities tailored to individual patient needs, reducing the risk of under- or overdosing. It minimizes wastage and ensures consistent therapeutic outcomes, improving overall treatment efficacy. This method supports real-time adjustments and better inventory management compared to batch dosing systems.

Advantages of Batch Dosing

Batch dosing offers superior efficiency when handling large production volumes, enabling consistent formulation across entire batches, which minimizes variability and enhances product reliability. This method reduces operational downtime and waste by preparing ingredients in bulk, resulting in cost savings and streamlined workflow. By using batch dosing, your manufacturing process gains scalability and improved quality control, essential for maintaining high production standards.

Accuracy and Consistency in Dosing Methods

Precise dosing offers superior accuracy by delivering exact quantities for each dose, minimizing variations and ensuring consistent therapeutic effects. Batch dosing, while efficient for large volumes, can suffer from slight inconsistencies due to mixing and sampling errors, potentially affecting potency across batches. Your choice of dosing method should prioritize the required precision and consistency to meet specific quality standards in pharmaceutical or chemical applications.

Applications in Pharmaceuticals and Manufacturing

Precise dosing techniques in pharmaceuticals ensure accurate measurement of active ingredients, crucial for drug efficacy and patient safety, especially in sterile manufacturing environments. Batch dosing is commonly used in large-scale manufacturing where consistency across batches is essential for regulatory compliance and quality control. Both dosing methods enhance production efficiency but precise dosing is critical for personalized medicine and complex formulations requiring exact ingredient quantities.

Cost Implications: Precise vs Batch Dosing

Precise dosing reduces material waste and lowers overall production costs by delivering exact quantities needed for each batch, enhancing resource efficiency. Batch dosing often leads to higher material consumption and increased inventory expenses due to overestimations and leftover ingredients. Cost implications favor precise dosing in industries aiming to minimize waste and optimize raw material utilization.

Equipment and Technology for Dosing Systems

Precise dosing systems utilize advanced volumetric or gravimetric technologies, including automated pumps and flow meters, to deliver exact quantities of liquids or powders, ensuring minimal waste and high accuracy in production. Batch dosing equipment often relies on traditional weigh scales and manual input, suitable for large volume mixing but less efficient for applications requiring tight tolerance control. Modern precise dosing solutions integrate real-time monitoring and feedback loops, enhancing consistency and reducing human error compared to conventional batch dosing setups.

Quality Control Measures in Dosing

Quality control measures in precise dosing involve automated systems with real-time monitoring and feedback loops to ensure exact quantities are delivered, minimizing human error and enhancing product consistency. Batch dosing relies on manual checks and periodic sampling, which can introduce variability and increase the risk of deviation from specifications. Implementing advanced sensors and integration with data analytics in precise dosing significantly improves accuracy and traceability compared to traditional batch dosing methods.

Choosing the Right Dosing Method for Your Process

Choosing the right dosing method for your process depends on the required accuracy and operational scale. Precise dosing offers exact measurements for small-scale or critical applications, ensuring consistent quality and minimal waste. Batch dosing suits larger volumes where speed and efficiency outweigh the need for pinpoint accuracy.

Precise dosing vs batch dosing Infographic

libmatt.com

libmatt.com