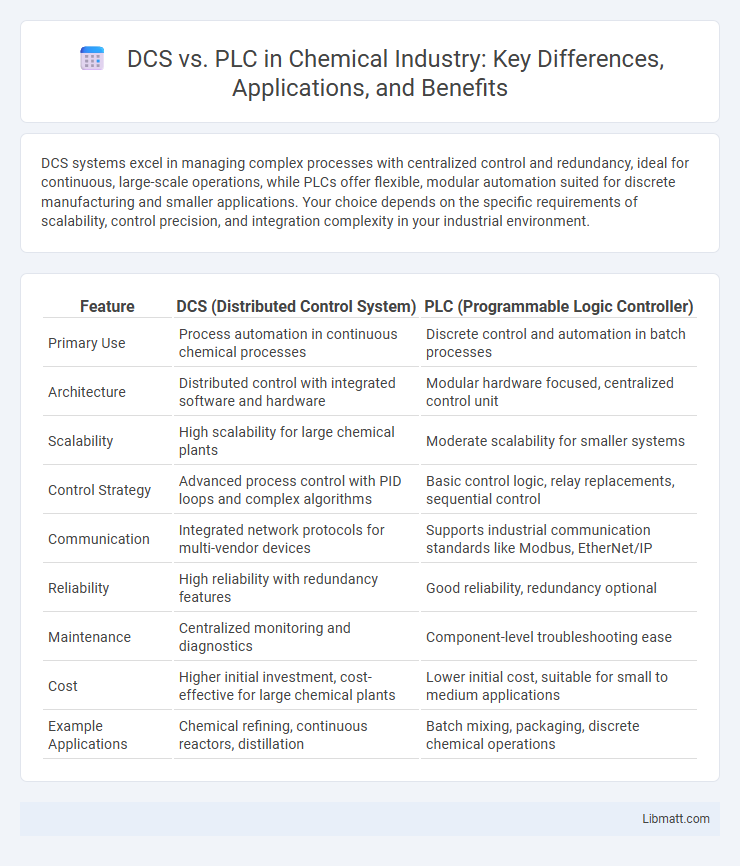

DCS systems excel in managing complex processes with centralized control and redundancy, ideal for continuous, large-scale operations, while PLCs offer flexible, modular automation suited for discrete manufacturing and smaller applications. Your choice depends on the specific requirements of scalability, control precision, and integration complexity in your industrial environment.

Table of Comparison

| Feature | DCS (Distributed Control System) | PLC (Programmable Logic Controller) |

|---|---|---|

| Primary Use | Process automation in continuous chemical processes | Discrete control and automation in batch processes |

| Architecture | Distributed control with integrated software and hardware | Modular hardware focused, centralized control unit |

| Scalability | High scalability for large chemical plants | Moderate scalability for smaller systems |

| Control Strategy | Advanced process control with PID loops and complex algorithms | Basic control logic, relay replacements, sequential control |

| Communication | Integrated network protocols for multi-vendor devices | Supports industrial communication standards like Modbus, EtherNet/IP |

| Reliability | High reliability with redundancy features | Good reliability, redundancy optional |

| Maintenance | Centralized monitoring and diagnostics | Component-level troubleshooting ease |

| Cost | Higher initial investment, cost-effective for large chemical plants | Lower initial cost, suitable for small to medium applications |

| Example Applications | Chemical refining, continuous reactors, distillation | Batch mixing, packaging, discrete chemical operations |

Introduction to DCS and PLC

Distributed Control Systems (DCS) are designed for complex, large-scale industrial processes, enabling centralized monitoring and control with high reliability and scalability. Programmable Logic Controllers (PLC) are versatile, compact control devices mainly used for automation of discrete processes, offering fast response times and easy programming. Your choice between DCS and PLC depends on the application's complexity, control requirements, and integration needs.

Key Differences Between DCS and PLC

Distributed Control Systems (DCS) are designed for complex, large-scale industrial processes requiring integrated control and monitoring, while Programmable Logic Controllers (PLC) excel in discrete manufacturing with faster, task-specific automation. DCS provides advanced data handling, centralized control, and built-in redundancy suited for continuous process industries, whereas PLC systems offer modularity, flexibility, and straightforward programming for quick response and localized control tasks. The fundamental distinction lies in DCS's system-wide integration and hierarchical control versus PLC's focus on decentralized, high-speed control of individual machines or processes.

Architecture Comparison: DCS vs PLC

DCS architecture integrates control, monitoring, and data acquisition in a centralized system ideal for complex, large-scale industrial processes, featuring multiple interconnected controllers and operator interfaces. PLC architecture is modular and decentralized, designed for discrete control tasks with individual controllers communicating over networks, offering flexibility and easier scalability for smaller or simpler applications. Your choice depends on process complexity and scalability requirements, with DCS excelling in continuous processes and PLCs suited for discrete automation tasks.

Typical Applications of DCS and PLC

Distributed Control Systems (DCS) are typically used in large-scale, continuous process industries such as oil refineries, power plants, and chemical manufacturing due to their ability to handle complex control and real-time data integration. Programmable Logic Controllers (PLC) are commonly applied in discrete manufacturing processes like automotive assembly lines, packaging, and robotics, where fast, reliable control of machinery and processes is essential. The choice between DCS and PLC depends on the scale, complexity, and nature of the industrial process being automated.

Scalability and Flexibility in DCS and PLC Solutions

Distributed Control Systems (DCS) offer superior scalability by enabling seamless expansion through modular hardware and software configurations ideal for large-scale industrial processes. Programmable Logic Controllers (PLCs) provide high flexibility with customizable programming and easy integration into diverse automation tasks, making them suitable for small to medium applications. DCS excels in continuous process control environments, while PLCs adapt efficiently to discrete operations and evolving production requirements.

Performance and Response Time

Distributed Control Systems (DCS) typically offer higher performance and faster response times in complex, large-scale industrial processes due to their integrated architecture and dedicated control loops. Programmable Logic Controllers (PLC) provide rapid response times in discrete control applications but may face limitations in handling extensive process control tasks compared to DCS. The real-time processing capability in DCS ensures optimized performance for continuous operations, while PLCs excel in high-speed, deterministic control in manufacturing environments.

Integration Capabilities and Communication Protocols

Distributed Control Systems (DCS) offer superior integration capabilities with complex industrial processes through advanced communication protocols like OPC UA, Modbus TCP/IP, and Profibus, enabling seamless data exchange and centralized control. Programmable Logic Controllers (PLC) support more flexible and modular integration, commonly utilizing protocols such as Ethernet/IP, Profinet, and DeviceNet, which suit discrete automation tasks and machine-level communication. The choice between DCS and PLC depends on the scale and complexity of the system's integration requirements and the compatibility with existing industrial networks.

Cost Analysis: Initial Investment and Maintenance

DCS systems typically require a higher initial investment due to integrated hardware and specialized software tailored for complex process control, while PLCs offer a more cost-effective entry point with modular components suitable for smaller-scale automation. Maintenance costs for DCS tend to be lower over time because of centralized diagnostics and vendor support, whereas PLC maintenance can become expensive as system complexity increases and multiple vendors are involved. Comprehensive cost analysis must consider scalability, system uptime, and long-term operational efficiency to determine the optimal choice between DCS and PLC.

Reliability, Safety, and Redundancy

DCS systems excel in reliability and redundancy with their distributed architecture, enabling continuous operation even if individual components fail, which is crucial for complex industrial processes. PLCs offer high reliability and are suited for discrete control tasks but typically rely on external redundancy configurations to achieve the same level of fault tolerance found in DCS. For ensuring maximum safety and uptime in critical operations, your choice should consider that DCS provides built-in safety features and redundancy, while PLC systems require additional modules to match this capability.

Choosing the Right System: DCS or PLC

Selecting between a Distributed Control System (DCS) and a Programmable Logic Controller (PLC) depends on the complexity and scale of the industrial process. DCS excels in large-scale, continuous processes with integrated feedback loops and extensive control points, providing centralized monitoring and advanced process control features. PLCs are ideal for discrete manufacturing and simple automation tasks due to their flexibility, ease of programming, and faster response times in smaller, modular applications.

DCS vs PLC Infographic

libmatt.com

libmatt.com