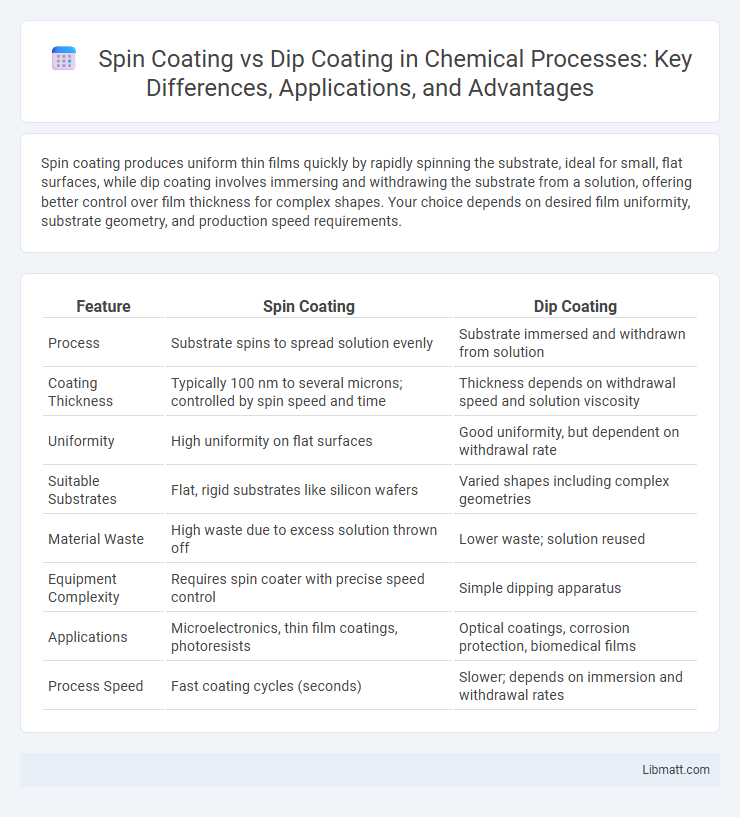

Spin coating produces uniform thin films quickly by rapidly spinning the substrate, ideal for small, flat surfaces, while dip coating involves immersing and withdrawing the substrate from a solution, offering better control over film thickness for complex shapes. Your choice depends on desired film uniformity, substrate geometry, and production speed requirements.

Table of Comparison

| Feature | Spin Coating | Dip Coating |

|---|---|---|

| Process | Substrate spins to spread solution evenly | Substrate immersed and withdrawn from solution |

| Coating Thickness | Typically 100 nm to several microns; controlled by spin speed and time | Thickness depends on withdrawal speed and solution viscosity |

| Uniformity | High uniformity on flat surfaces | Good uniformity, but dependent on withdrawal rate |

| Suitable Substrates | Flat, rigid substrates like silicon wafers | Varied shapes including complex geometries |

| Material Waste | High waste due to excess solution thrown off | Lower waste; solution reused |

| Equipment Complexity | Requires spin coater with precise speed control | Simple dipping apparatus |

| Applications | Microelectronics, thin film coatings, photoresists | Optical coatings, corrosion protection, biomedical films |

| Process Speed | Fast coating cycles (seconds) | Slower; depends on immersion and withdrawal rates |

Introduction to Spin Coating and Dip Coating

Spin coating involves rapidly spinning a substrate to spread a liquid film uniformly through centrifugal force, commonly used in semiconductor and optical industries for thin-film deposition. Dip coating entails immersing and withdrawing a substrate from a liquid solution at controlled speeds to form a uniform coating, widely applied in corrosion protection and biomedical devices. Both techniques offer precise control over film thickness and morphology, but differ in process dynamics and suitability for various materials.

Principles Behind Spin Coating

Spin coating involves depositing a liquid polymer or solution onto a substrate, which is then rapidly rotated to spread the material evenly by centrifugal force. The thickness of the coating is controlled by spin speed, viscosity of the solution, and spin time, allowing for precise and uniform thin films. This technique is preferred for producing highly consistent coatings in microelectronics and nanotechnology applications.

Principles Behind Dip Coating

Dip coating relies on the principle of immersing a substrate into a liquid solution and then withdrawing it at a controlled speed, allowing a thin film to form through evaporation or drying. The coating thickness is influenced by factors such as withdrawal speed, solution viscosity, and surface tension. Your choice between dip coating and spin coating depends on the desired film uniformity, thickness control, and substrate geometry.

Key Differences Between Spin Coating and Dip Coating

Spin coating involves depositing a liquid film on a substrate by spinning it at high speeds, resulting in uniform thin films, while dip coating immerses the substrate into a solution and withdraws it at controlled speeds to form coatings of varying thickness. Spin coating offers precise control over film thickness and surface uniformity, commonly used in semiconductor and optical applications, whereas dip coating is favored for coating complex shapes and larger surfaces with adjustable thickness. Your choice depends on factors such as substrate geometry, desired film uniformity, and application requirements.

Advantages of Spin Coating

Spin coating offers rapid film formation with exceptional uniformity and thickness control, making it ideal for producing thin, consistent coatings in microfabrication and electronics. Its ability to achieve high-speed deposition reduces processing time and material waste compared to dip coating. Spin coating also provides superior reproducibility and surface smoothness, critical for applications in semiconductors, photovoltaics, and biomedical devices.

Advantages of Dip Coating

Dip coating offers superior uniformity and thickness control for thin films, especially on complex or irregular substrates. Its scalability makes it ideal for large-area coatings in industrial applications, providing consistent material deposition with minimal waste. The process is also versatile, compatible with a wide range of materials including polymers, ceramics, and metals, enhancing its application scope compared to spin coating.

Limitations and Challenges

Spin coating faces challenges such as material wastage due to rapid centrifugal spreading and difficulty achieving uniform coatings on non-flat surfaces. Dip coating struggles with issues like inconsistent film thickness caused by gravitational effects during withdrawal and limitations in coating complex geometries uniformly. Both methods require precise control of parameters like viscosity, withdrawal speed, and ambient conditions to minimize defects and achieve desired film properties.

Applications in Industry and Research

Spin coating is widely used in semiconductor manufacturing and microelectronics for producing uniform thin films on wafers due to its high precision and speed. Dip coating is favored in biomedical and materials science research for coating complex three-dimensional substrates and creating multilayer structures because of its versatility. Both techniques are critical in optical coatings, sensors, and nanotechnology, with spin coating excelling in uniformity and dip coating offering adaptability to diverse substrate geometries.

Material Compatibility Considerations

Spin coating excels in applying uniform thin films on flat, smooth substrates like silicon wafers and glass due to its controlled centrifugal force, but it may struggle with irregularly shaped or porous materials. Dip coating offers versatile material compatibility, effectively coating complex geometries and porous substrates such as ceramics and textiles by immersing the substrate directly into the coating solution. Both methods require consideration of solvent volatility and surface energy to ensure optimal adhesion and coating uniformity across different material types.

Choosing the Right Coating Method

Selecting the right coating method depends on your substrate type, desired film thickness, and uniformity requirements. Spin coating offers precise control over thin film thickness and is ideal for flat, small substrates, while dip coating excels in coating complex shapes and provides uniform layers over larger surfaces. Understanding these factors ensures optimal performance and efficiency in your coating process.

Spin coating vs dip coating Infographic

libmatt.com

libmatt.com