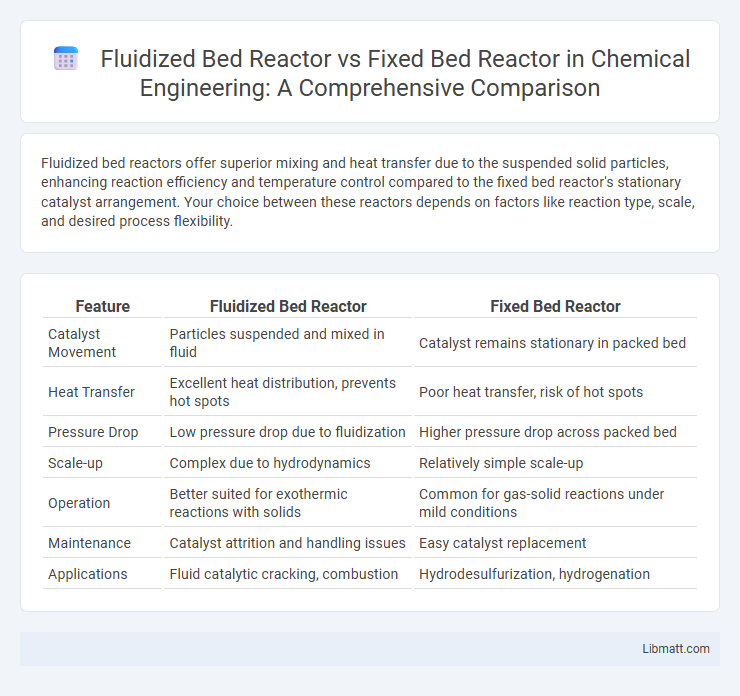

Fluidized bed reactors offer superior mixing and heat transfer due to the suspended solid particles, enhancing reaction efficiency and temperature control compared to the fixed bed reactor's stationary catalyst arrangement. Your choice between these reactors depends on factors like reaction type, scale, and desired process flexibility.

Table of Comparison

| Feature | Fluidized Bed Reactor | Fixed Bed Reactor |

|---|---|---|

| Catalyst Movement | Particles suspended and mixed in fluid | Catalyst remains stationary in packed bed |

| Heat Transfer | Excellent heat distribution, prevents hot spots | Poor heat transfer, risk of hot spots |

| Pressure Drop | Low pressure drop due to fluidization | Higher pressure drop across packed bed |

| Scale-up | Complex due to hydrodynamics | Relatively simple scale-up |

| Operation | Better suited for exothermic reactions with solids | Common for gas-solid reactions under mild conditions |

| Maintenance | Catalyst attrition and handling issues | Easy catalyst replacement |

| Applications | Fluid catalytic cracking, combustion | Hydrodesulfurization, hydrogenation |

Introduction to Fluidized Bed and Fixed Bed Reactors

Fluidized bed reactors use a fluidizing gas or liquid to suspend solid catalyst particles, enhancing heat and mass transfer for improved reaction efficiency. Fixed bed reactors consist of static catalyst pellets packed in a column, offering simplicity and effective handling of catalytic processes with lower operational complexity. Your choice depends on factors like reaction kinetics, temperature control, and scalability needs.

Fundamental Principles of Operation

Fluidized bed reactors operate by suspending solid catalyst particles in an upward-flowing fluid, creating a dynamic mixing effect that enhances heat and mass transfer rates. Fixed bed reactors maintain a stationary packed bed of catalyst particles through which reactants flow, resulting in relatively lower mixing and heat distribution capabilities. The fluidization in fluidized bed reactors allows for improved temperature control and uniform reaction conditions compared to the fixed, more stagnant environment of fixed bed reactors.

Key Design Features and Configurations

Fluidized bed reactors feature a bed of solid catalyst particles suspended by an upward flow of fluid, promoting excellent mixing and uniform temperature distribution, which enhances reaction rates and heat transfer. Fixed bed reactors consist of a stationary catalyst packed tightly in a tube or vessel, offering simpler design and lower operational complexity but may suffer from channeling and hot spots due to limited mixing. Your choice between these reactors depends on factors like catalyst type, reaction kinetics, and scale, with fluidized beds suited for highly exothermic reactions and fixed beds preferred for processes requiring precise control over residence time.

Advantages of Fluidized Bed Reactors

Fluidized bed reactors offer superior heat and mass transfer due to the intense mixing of particles, enhancing reaction rates and uniform temperature distribution. They provide better catalyst utilization and prevent channeling, making them ideal for handling large volumes and varying feedstock compositions. Your processes can benefit from easier scale-up and improved control over reaction conditions compared to fixed bed reactors.

Advantages of Fixed Bed Reactors

Fixed bed reactors offer advantages such as simple design, ease of operation, and high catalyst contact efficiency, making them ideal for processes requiring longer catalyst residence times. Their well-defined flow patterns ensure uniform reaction conditions and enhanced temperature control, reducing hot spots and improving product selectivity. Fixed bed reactors also provide lower operational costs with minimal catalyst handling and maintenance requirements compared to fluidized bed systems.

Limitations and Challenges of Each Reactor Type

Fluidized bed reactors face challenges such as particle attrition, erosion of internal components, and difficulties in handling sticky or fine powders, which can lead to defluidization. Fixed bed reactors are limited by channeling, uneven temperature distribution, and pressure drop increases, which can reduce catalyst effectiveness and complicate scale-up processes. Both reactor types require careful management of hydrodynamic and thermal conditions to optimize performance and ensure operational longevity.

Application Areas and Industry Uses

Fluidized bed reactors are widely utilized in catalytic cracking, coal gasification, and biomass conversion due to their excellent heat and mass transfer capabilities. Fixed bed reactors find extensive use in hydrogenation, methanation, and adsorption processes within the chemical and petrochemical industries thanks to their simplicity and ease of catalyst replacement. Your choice between these reactors depends on the specific reaction kinetics and scale requirements in sectors like oil refining, pharmaceuticals, and environmental engineering.

Performance Comparison: Efficiency and Selectivity

Fluidized bed reactors offer superior mixing and heat transfer, resulting in higher efficiency and more uniform temperature distribution compared to fixed bed reactors. Fixed bed reactors generally provide better selectivity for certain catalytic reactions due to their controlled flow paths, reducing back-mixing effects. When optimizing your process, selecting a fluidized bed reactor can enhance overall reaction rates, while fixed bed reactors help maintain product selectivity.

Catalyst Handling and Maintenance Considerations

Fluidized bed reactors offer superior catalyst handling due to continuous catalyst movement that prevents hot spots and allows easy catalyst replacement or regeneration without shutdown. Fixed bed reactors require careful catalyst management since the catalyst remains stationary, making replacement or regeneration more time-consuming and often necessitating reactor shutdown. Maintenance of fluidized beds is generally simpler and more cost-effective, whereas fixed beds face challenges like channeling and catalyst deactivation that demand more frequent and intensive maintenance procedures.

Future Trends and Technology Developments

Future trends in fluidized bed reactors include advancements in real-time monitoring and control systems that enhance reaction efficiency and scalability for industrial applications. Fixed bed reactors are evolving with innovations in catalyst design and modular configurations to improve mass transfer and reduce pressure drop. Your choice between these reactors will increasingly depend on emerging technologies that optimize energy consumption and sustainability in chemical processing.

fluidized bed reactor vs fixed bed reactor Infographic

libmatt.com

libmatt.com