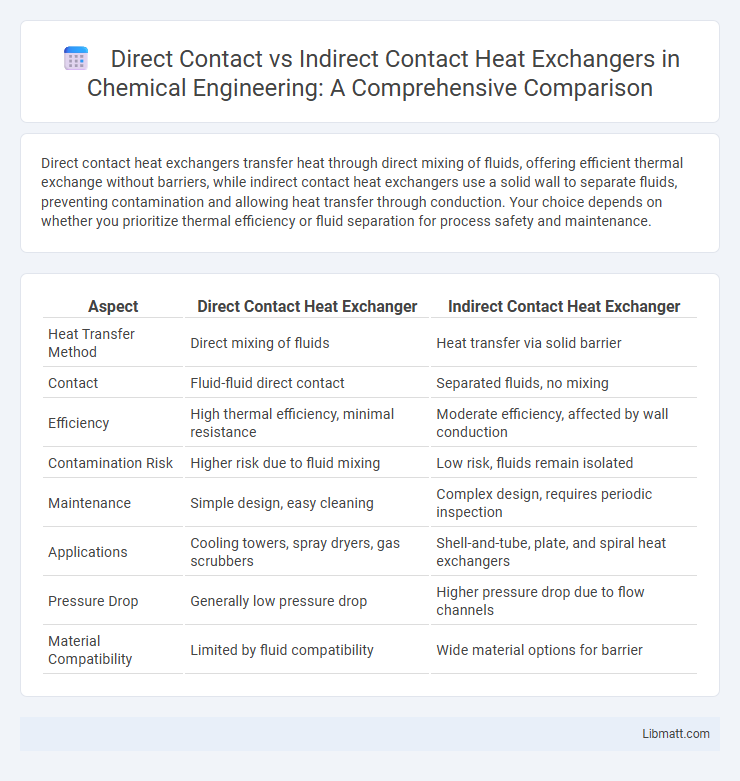

Direct contact heat exchangers transfer heat through direct mixing of fluids, offering efficient thermal exchange without barriers, while indirect contact heat exchangers use a solid wall to separate fluids, preventing contamination and allowing heat transfer through conduction. Your choice depends on whether you prioritize thermal efficiency or fluid separation for process safety and maintenance.

Table of Comparison

| Aspect | Direct Contact Heat Exchanger | Indirect Contact Heat Exchanger |

|---|---|---|

| Heat Transfer Method | Direct mixing of fluids | Heat transfer via solid barrier |

| Contact | Fluid-fluid direct contact | Separated fluids, no mixing |

| Efficiency | High thermal efficiency, minimal resistance | Moderate efficiency, affected by wall conduction |

| Contamination Risk | Higher risk due to fluid mixing | Low risk, fluids remain isolated |

| Maintenance | Simple design, easy cleaning | Complex design, requires periodic inspection |

| Applications | Cooling towers, spray dryers, gas scrubbers | Shell-and-tube, plate, and spiral heat exchangers |

| Pressure Drop | Generally low pressure drop | Higher pressure drop due to flow channels |

| Material Compatibility | Limited by fluid compatibility | Wide material options for barrier |

Introduction to Heat Exchangers

Heat exchangers transfer thermal energy between fluids to regulate temperature efficiently. Direct contact heat exchangers enable fluids to mix, allowing rapid heat transfer through direct fluid contact, enhancing thermal performance. Indirect contact heat exchangers use a separating wall to prevent fluid mixing, ensuring contamination control and precise temperature management for your applications.

Overview of Direct Contact Heat Exchangers

Direct contact heat exchangers facilitate heat transfer by allowing two fluid streams to mix and exchange thermal energy without physical barriers, enhancing heat transfer efficiency through direct interaction. These systems are commonly used in applications like cooling towers, spray ponds, and condensers where intimate fluid contact is practical. The absence of separating surfaces reduces fouling and maintenance but requires careful handling to prevent contamination between fluids.

Overview of Indirect Contact Heat Exchangers

Indirect contact heat exchangers transfer heat between two fluids separated by a solid barrier, preventing direct mixing and contamination. Common types include shell-and-tube, plate, and spiral heat exchangers, which optimize surface area for efficient thermal exchange. Your choice of an indirect contact heat exchanger ensures reliable temperature control in applications requiring fluid separation, such as chemical processing and HVAC systems.

Working Principles: Direct vs Indirect Contact

Direct contact heat exchangers transfer heat through intimate mixing of two fluids, allowing direct heat exchange without physical barriers, enhancing heat transfer efficiency and reducing temperature differences. Indirect contact heat exchangers use solid walls or surfaces to separate fluids, enabling heat transfer by conduction while preventing mixing, which is crucial for processes requiring fluid purity or phase separation. The choice depends on application requirements such as contamination risk, temperature range, and heat transfer effectiveness.

Design Differences and Applications

Direct contact heat exchangers facilitate heat transfer by allowing two fluids to come into physical contact, enhancing thermal efficiency in applications like cooling towers and spray ponds. Indirect contact heat exchangers use a solid barrier, such as metal plates or tubes, preventing fluid mixing and are ideal for systems requiring contamination prevention, like HVAC units and chemical processing. Your choice depends on factors like fluid compatibility, heat transfer rate, and maintenance needs.

Heat Transfer Efficiency Comparison

Direct contact heat exchangers typically achieve higher heat transfer efficiency due to the intimate mixing of two fluids, allowing for rapid thermal energy exchange without the resistance of a solid boundary. Indirect contact heat exchangers rely on a physical barrier, resulting in lower overall efficiency because heat must conduct through the separating material, introducing thermal resistance. Your choice depends on the application requirements, but for maximizing heat transfer efficiency, direct contact systems often outperform indirect designs.

Advantages of Direct Contact Heat Exchangers

Direct contact heat exchangers offer superior heat transfer efficiency by allowing direct fluid interaction, which eliminates thermal resistance typical in indirect methods. They require simpler construction and lower maintenance costs due to fewer components and no intermediate surfaces. You benefit from enhanced flexibility in handling phase changes and contaminants without fouling issues common in indirect contact systems.

Advantages of Indirect Contact Heat Exchangers

Indirect contact heat exchangers offer superior contamination control by preventing mixing of fluids, ideal for hygienic or hazardous applications. They provide precise temperature regulation and enhanced durability due to the use of durable metal surfaces and well-defined flow paths. Maintenance is simplified, and operational efficiency improves with reduced fouling and corrosion risks.

Key Limitations and Challenges

Direct contact heat exchangers face challenges such as contamination risks due to the mixing of fluids and difficulties in controlling the contact time and heat transfer rate precisely. Indirect contact heat exchangers have limitations including higher capital costs, potential fouling on heat transfer surfaces, and reduced thermal efficiency from heat losses through the exchanger walls. Both types encounter maintenance complexities and material compatibility issues, especially when handling aggressive or high-temperature fluids.

Selection Criteria for Industrial Applications

Direct contact heat exchangers offer higher heat transfer efficiency by allowing direct mixing of fluids, making them ideal for processes where product contamination is not a concern and easy maintenance is required. Indirect contact heat exchangers prevent fluid mixing through a solid barrier, providing better control over cross-contamination, which is crucial in industries like pharmaceuticals and food processing. Your selection depends on factors such as thermal efficiency, contamination risk, maintenance capabilities, and the specific industrial application requirements.

direct contact heat exchanger vs indirect contact heat exchanger Infographic

libmatt.com

libmatt.com