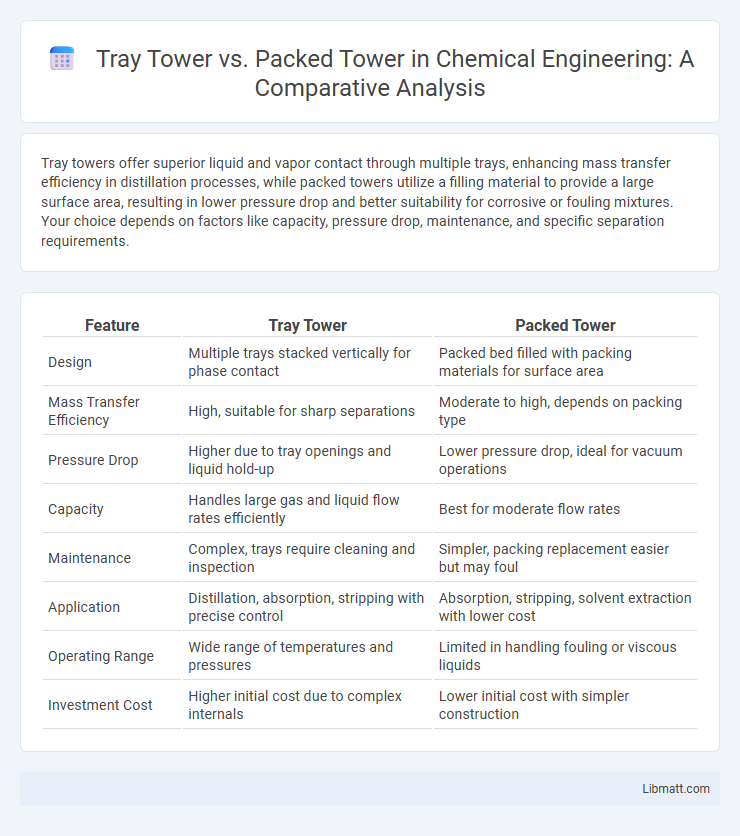

Tray towers offer superior liquid and vapor contact through multiple trays, enhancing mass transfer efficiency in distillation processes, while packed towers utilize a filling material to provide a large surface area, resulting in lower pressure drop and better suitability for corrosive or fouling mixtures. Your choice depends on factors like capacity, pressure drop, maintenance, and specific separation requirements.

Table of Comparison

| Feature | Tray Tower | Packed Tower |

|---|---|---|

| Design | Multiple trays stacked vertically for phase contact | Packed bed filled with packing materials for surface area |

| Mass Transfer Efficiency | High, suitable for sharp separations | Moderate to high, depends on packing type |

| Pressure Drop | Higher due to tray openings and liquid hold-up | Lower pressure drop, ideal for vacuum operations |

| Capacity | Handles large gas and liquid flow rates efficiently | Best for moderate flow rates |

| Maintenance | Complex, trays require cleaning and inspection | Simpler, packing replacement easier but may foul |

| Application | Distillation, absorption, stripping with precise control | Absorption, stripping, solvent extraction with lower cost |

| Operating Range | Wide range of temperatures and pressures | Limited in handling fouling or viscous liquids |

| Investment Cost | Higher initial cost due to complex internals | Lower initial cost with simpler construction |

Introduction to Tray Towers and Packed Towers

Tray towers utilize horizontal trays to hold liquid and vapor phases, promoting intense contact and efficient mass transfer in distillation or absorption processes. Packed towers contain structured or random packing materials, offering high surface area for vapor-liquid interaction while minimizing pressure drop, ideal for operations requiring energy efficiency. Your choice between tray and packed towers depends on factors like capacity, pressure drop, and maintenance needs for optimal separation performance.

Basic Principles of Mass Transfer in Towers

Tray towers operate by directing vapor through perforated trays, allowing intimate contact between vapor and liquid for effective mass transfer, while packed towers rely on packing material that creates a large surface area for vapor-liquid interaction. Mass transfer in both systems occurs through diffusion and convection, driven by concentration gradients between phases, but tray towers often handle higher liquid loads better and provide easier stage control. Your choice between tray and packed towers should consider factors such as mass transfer efficiency, pressure drop, liquid distribution, and operational flexibility depending on the specific separation process.

Design and Construction of Tray Towers

Tray towers feature multiple horizontal trays spaced vertically inside a column, allowing vapor and liquid to interact for mass transfer, designed with bubble cap, sieve, or valve trays to optimize efficiency. The construction involves precise tray spacing, vapor and liquid distribution systems, and support structures to withstand operational pressures and temperatures. Material selection and mechanical design ensure durability and maintainability in corrosive or high-temperature environments.

Design and Construction of Packed Towers

Packed towers feature a simpler design compared to tray towers, utilizing a vertical column filled with packing materials such as structured or random packing to enhance surface area for mass transfer. The construction of packed towers involves selecting appropriate packing type and size, ensuring uniform liquid and gas distribution, and designing for pressure drop and capacity to optimize performance. This design reduces operational complexity and maintenance needs, making packed towers ideal for applications requiring efficient gas-liquid contact with lower liquid hold-up and fouling risks.

Efficiency and Performance Comparison

Tray towers offer higher mass transfer efficiency due to staged contact between vapor and liquid phases, making them suitable for complex separations where precise control is needed. Packed towers provide a larger surface area and lower pressure drop, enhancing performance in operations requiring consistent liquid distribution and lower energy consumption. Your choice depends on process requirements; tray towers excel in efficiency for multi-stage separations, while packed towers are preferred for simpler, cost-effective applications.

Pressure Drop Characteristics

Tray towers typically exhibit higher pressure drop because gas flows through perforated trays, causing turbulence and resistance, which might affect your energy efficiency. Packed towers generally have lower pressure drop due to the continuous packing material offering less obstruction to gas flow, promoting smoother mass transfer. Selecting between the two depends on balancing pressure drop considerations with separation efficiency for your specific application.

Operational Flexibility and Scalability

Tray towers provide higher operational flexibility with the ability to adjust tray spacing, number, and type, enabling precise control over separation efficiency and capacity. Packed towers offer superior scalability due to their modular packing materials, allowing easy modifications to accommodate varying flow rates and process intensities. Your choice between tray and packed towers should consider the specific operational demands and future scalability requirements of your process.

Common Applications in Industry

Tray towers are commonly used in refining processes such as distillation of crude oil and separation of chemical mixtures, offering efficient vapor-liquid contact with easy maintenance. Packed towers excel in applications requiring gentle handling of liquids, such as absorption, stripping, and gas scrubbing in chemical, petrochemical, and environmental industries. Your choice depends on factors like pressure drop tolerance, liquid distribution, and specific separation requirements in your industrial process.

Maintenance and Operational Challenges

Tray towers require frequent maintenance due to tray damage and fouling, which can lead to increased downtime and operational costs. Packed towers offer easier cleaning and lower risks of mechanical failure, but they may face challenges with channeling and pressure drop over time. Your choice impacts maintenance schedules and operational efficiency depending on process demands and contamination levels.

Selection Criteria: When to Use Tray vs Packed Towers

Tray towers are ideal for processes requiring precise stagewise separation with handling of high liquid loads and fouling materials, offering better control and easier maintenance. Packed towers suit applications with lower pressure drops, smaller footprints, and efficient mass transfer in liquid-gas contact, especially when dealing with low liquid flow rates or corrosive fluids. Your selection depends heavily on factors like flow rates, pressure drop limitations, maintenance ease, and specific separation requirements.

tray tower vs packed tower Infographic

libmatt.com

libmatt.com