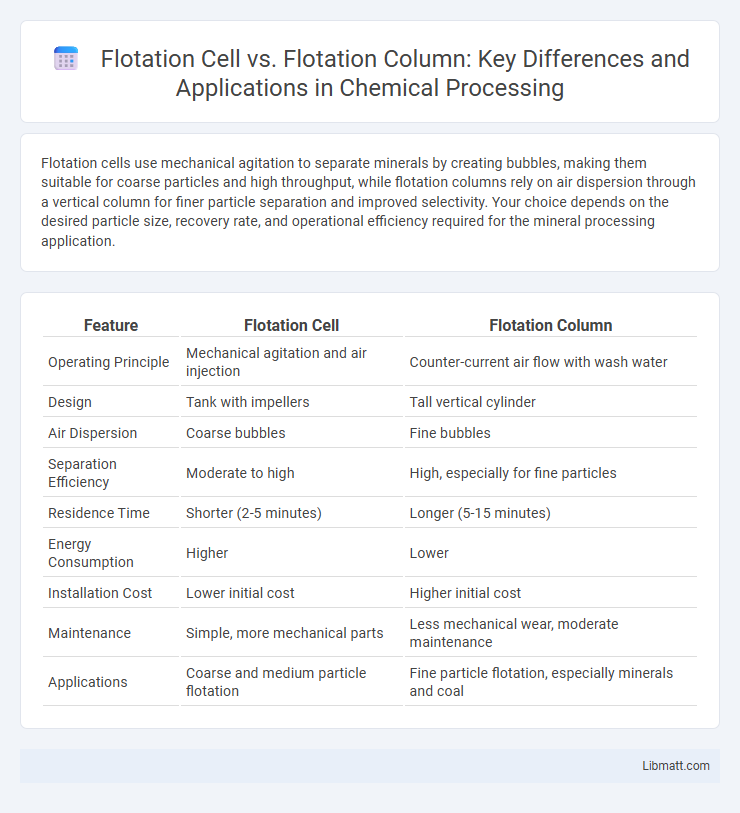

Flotation cells use mechanical agitation to separate minerals by creating bubbles, making them suitable for coarse particles and high throughput, while flotation columns rely on air dispersion through a vertical column for finer particle separation and improved selectivity. Your choice depends on the desired particle size, recovery rate, and operational efficiency required for the mineral processing application.

Table of Comparison

| Feature | Flotation Cell | Flotation Column |

|---|---|---|

| Operating Principle | Mechanical agitation and air injection | Counter-current air flow with wash water |

| Design | Tank with impellers | Tall vertical cylinder |

| Air Dispersion | Coarse bubbles | Fine bubbles |

| Separation Efficiency | Moderate to high | High, especially for fine particles |

| Residence Time | Shorter (2-5 minutes) | Longer (5-15 minutes) |

| Energy Consumption | Higher | Lower |

| Installation Cost | Lower initial cost | Higher initial cost |

| Maintenance | Simple, more mechanical parts | Less mechanical wear, moderate maintenance |

| Applications | Coarse and medium particle flotation | Fine particle flotation, especially minerals and coal |

Introduction to Flotation Technologies

Flotation cell and flotation column are key flotation technologies used in mineral processing to separate valuable minerals from ores based on differences in surface properties. Flotation cells operate with mechanical agitation and air dispersion to create bubbles for mineral attachment, while flotation columns utilize a tall, cylindrical design to enhance bubble-particle contact and improve separation efficiency through counter-current flow. The choice between flotation cell and flotation column depends on factors such as feed particle size, mineralogy, and desired recovery rates in processing plants.

Overview of Flotation Cell and Flotation Column

Flotation cells use mechanical agitation to generate bubbles that separate minerals based on their hydrophobic properties, providing efficient mixing and high recovery rates in mineral processing. Flotation columns rely on the counter-current flow of slurry and air bubbles in a tall column, enhancing selectivity and producing higher concentrate grades by promoting long bubble-particle contact times. Your choice between flotation cells and columns depends on the desired balance of recovery efficiency and concentrate quality in mineral beneficiation.

Design Differences: Cell vs. Column

Flotation cells feature mechanical agitation with impellers and rotors creating turbulent mixing, while flotation columns utilize air spargers and wash water for gentle, counter-current flow, enhancing particle-bubble contact. Cells are typically rectangular or cylindrical tanks equipped with mechanical internal components, whereas columns are tall, slender vessels that rely on their height for improved separation efficiency. Your choice between a flotation cell vs. flotation column depends on the specific design benefits each offers for targeted mineral recovery and processing conditions.

Operating Principles and Mechanisms

Flotation cells operate using mechanical agitation to create fine air bubbles that attach to hydrophobic particles, enabling their separation from the slurry through froth formation. Flotation columns rely on a counter-current flow system where air is introduced from the bottom, generating microbubbles that promote particle-bubble contact via a laminar flow, enhancing selectivity and recovery. The distinct flow dynamics and bubble generation mechanisms in cells and columns significantly influence their efficiency in mineral processing applications.

Efficiency and Recovery Performance Comparison

Flotation columns generally exhibit higher recovery rates and improved selectivity compared to flotation cells due to their enhanced air dispersion and longer residence time, which promote better particle-bubble contact. Flotation cells offer greater flexibility and capacity for coarse particles but may have lower efficiency in fine mineral recovery. The choice between flotation cell and flotation column depends on ore characteristics and desired mineral recovery, with columns favored for fine particle processing and cells preferred for robustness in diverse applications.

Application Areas in Mineral Processing

Flotation cells excel in processing ores with coarse particles, making them ideal for copper, lead, zinc, and molybdenum extraction. Flotation columns are preferred for fine particles and complex sulfide ores, enhancing recovery of minerals such as gold and phosphate. Your choice between the two depends on the ore type and desired mineral recovery efficiency in your mineral processing plant.

Energy Consumption and Cost Analysis

Flotation cells generally consume more energy than flotation columns due to their mechanical agitation and aeration systems, leading to higher operational costs in mineral processing plants. Flotation columns utilize air sparging and counter-current flow which requires less power and improves energy efficiency, resulting in lower total cost per ton of processed material. Cost analysis shows that despite higher initial capital investment, flotation columns reduce energy expenses and maintenance costs over time, making them economically advantageous for fine particle recovery.

Maintenance and Operational Challenges

Flotation cells require frequent maintenance due to mechanical components like impellers and bearings that wear out, leading to higher downtime and repair costs. Flotation columns feature fewer moving parts, reducing maintenance demands but pose operational challenges such as sensitivity to feed conditions and air flow control. Optimizing froth recovery in columns demands precise monitoring, whereas flotation cells offer more robust performance in varying process conditions but at the expense of increased mechanical upkeep.

Environmental Impact and Sustainability

Flotation cells typically consume more energy due to mechanical agitation, leading to higher carbon emissions compared to flotation columns, which use air sparging and require less power. Flotation columns generate finer bubbles and improved phase separation, enhancing recovery rates and reducing chemical reagent usage that minimizes environmental contamination. The sustained efficiency and lower operational footprint of flotation columns align better with sustainable mining practices by decreasing waste production and water usage.

Choosing the Right Technology: Key Considerations

Choosing the right flotation technology depends on factors such as ore mineralogy, recovery rates, and operational costs, with flotation cells offering mechanical agitation suited for coarse particles, while flotation columns provide improved selectivity and ultrafine particle recovery through counter-current flow and froth washing. Your process demands careful evaluation of concentrate grade, throughput capacity, and energy consumption to optimize performance. Selecting between flotation cells and columns can significantly impact metallurgical outcomes, so balancing efficiency and cost-effectiveness is crucial.

Flotation cell vs flotation column Infographic

libmatt.com

libmatt.com