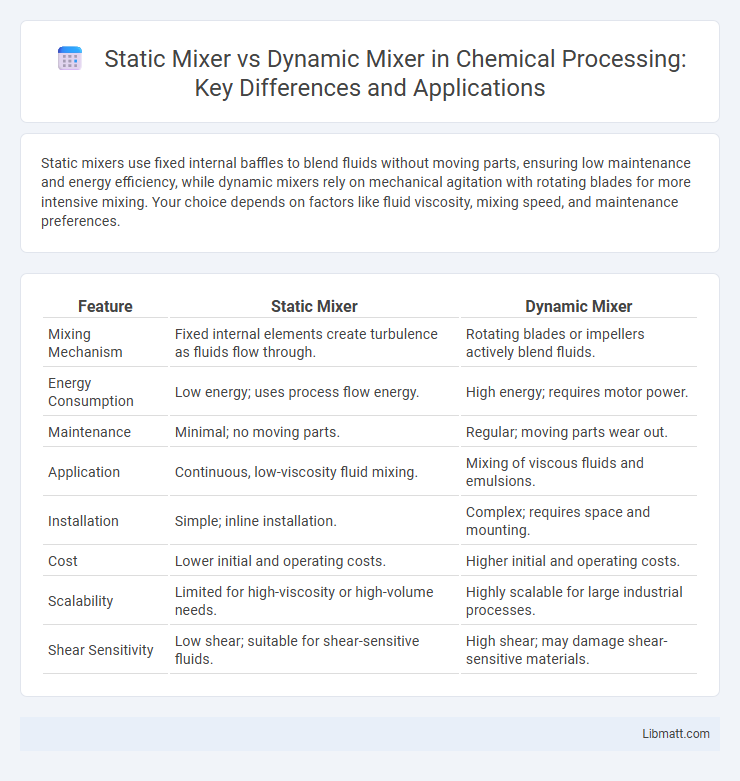

Static mixers use fixed internal baffles to blend fluids without moving parts, ensuring low maintenance and energy efficiency, while dynamic mixers rely on mechanical agitation with rotating blades for more intensive mixing. Your choice depends on factors like fluid viscosity, mixing speed, and maintenance preferences.

Table of Comparison

| Feature | Static Mixer | Dynamic Mixer |

|---|---|---|

| Mixing Mechanism | Fixed internal elements create turbulence as fluids flow through. | Rotating blades or impellers actively blend fluids. |

| Energy Consumption | Low energy; uses process flow energy. | High energy; requires motor power. |

| Maintenance | Minimal; no moving parts. | Regular; moving parts wear out. |

| Application | Continuous, low-viscosity fluid mixing. | Mixing of viscous fluids and emulsions. |

| Installation | Simple; inline installation. | Complex; requires space and mounting. |

| Cost | Lower initial and operating costs. | Higher initial and operating costs. |

| Scalability | Limited for high-viscosity or high-volume needs. | Highly scalable for large industrial processes. |

| Shear Sensitivity | Low shear; suitable for shear-sensitive fluids. | High shear; may damage shear-sensitive materials. |

Introduction to Static and Dynamic Mixers

Static mixers use fixed internal elements to create flow division and radial mixing within pipelines without moving parts, offering energy-efficient and low-maintenance solutions for blending fluids. Dynamic mixers incorporate rotating components such as impellers or blades, providing rapid and thorough mixing suitable for high-viscosity fluids and processes requiring intense shear forces. Selection between static and dynamic mixers depends on factors like fluid properties, mixing intensity, maintenance requirements, and operational costs.

Key Differences Between Static and Dynamic Mixers

Static mixers rely on fixed internal elements to create turbulent flow for blending fluids without moving parts, offering low maintenance and energy efficiency. Dynamic mixers use rotating components to provide intensive mixing, enabling faster blending and handling of viscous materials but requiring higher energy input and regular maintenance. Your choice depends on the application's fluid properties, required mixing speed, and operational costs.

How Static Mixers Work

Static mixers work by using stationary, helical elements inserted inside a pipe to create turbulence and promote mixing as fluids flow through them. These elements continuously split and recombine the fluid streams, enhancing blend uniformity without moving parts or external power. The design ensures efficient mixing for liquids, gases, or multiphase flows, making static mixers energy-efficient and low-maintenance compared to dynamic mixers with rotating components.

How Dynamic Mixers Operate

Dynamic mixers operate using a motor-driven impeller or rotor that continuously agitates fluids to achieve thorough blending, enhancing mixing efficiency in viscous or multi-phase systems. The rotating blades create shear forces and turbulence, promoting rapid homogenization and reducing mixing time compared to static mixers. This mechanical agitation allows dynamic mixers to handle complex mixing tasks in industries such as chemical processing, wastewater treatment, and food production.

Applications of Static Mixers

Static mixers excel in applications requiring efficient blending of fluids in pipelines such as chemical processing, water treatment, and food production due to their low maintenance and energy efficiency. They are ideal for continuous mixing tasks involving liquids, gases, or multiphase flows, including blending additives, neutralizing acids, and dispersing gases into liquids. Their stationary design enables consistent mixing performance in heating, cooling, and reaction processes without moving parts or external power sources.

Applications of Dynamic Mixers

Dynamic mixers are widely used in industries requiring rapid and thorough blending of liquids with varying viscosities, such as chemical processing, pharmaceuticals, and food production. Their applications include emulsification, gas dispersion, and homogenization where consistent shear forces accelerate mixing efficiency. Your processes benefit from dynamic mixers' ability to handle high-viscosity fluids and offer precise control over mixing speed and intensity.

Advantages of Static Mixers

Static mixers offer several advantages, including low energy consumption due to the absence of moving parts, which reduces operational costs and maintenance requirements. Their simple design provides reliable and consistent mixing with minimal risk of mechanical failure, making them ideal for continuous processes. You benefit from a compact size and easy installation, which makes static mixers suitable for a wide range of industries such as chemical, pharmaceutical, and water treatment.

Advantages of Dynamic Mixers

Dynamic mixers offer superior mixing efficiency due to their ability to continuously agitate fluids through mechanical motion, resulting in faster and more homogeneous blending compared to static mixers. They handle high-viscosity materials and varying flow rates more effectively, ensuring consistent product quality in complex industrial processes. Your operations benefit from enhanced flexibility and improved control over mixing parameters, making dynamic mixers ideal for demanding applications.

Choosing the Right Mixer for Your Process

Selecting between a static mixer and a dynamic mixer depends on your process requirements, such as flow rates, mixing intensity, and maintenance preferences. Static mixers offer low-energy, maintenance-free operation ideal for continuous processes with consistent flow, while dynamic mixers provide superior mixing for high-viscosity fluids and fluctuating conditions due to their mechanical agitation. Evaluating your process variables ensures optimal efficiency and product quality with the right mixer choice.

Cost and Maintenance Considerations

Static mixers generally offer lower initial costs and minimal maintenance due to their lack of moving parts, making them ideal for simple, continuous mixing processes. Dynamic mixers require higher upfront investment and incur regular maintenance expenses because of their mechanical components, including motors and gears that are prone to wear and tear. Cost efficiency favors static mixers for low-viscosity fluids and less demanding applications, while dynamic mixers are preferred for handling complex or high-viscosity materials despite higher operational costs.

static mixer vs dynamic mixer Infographic

libmatt.com

libmatt.com