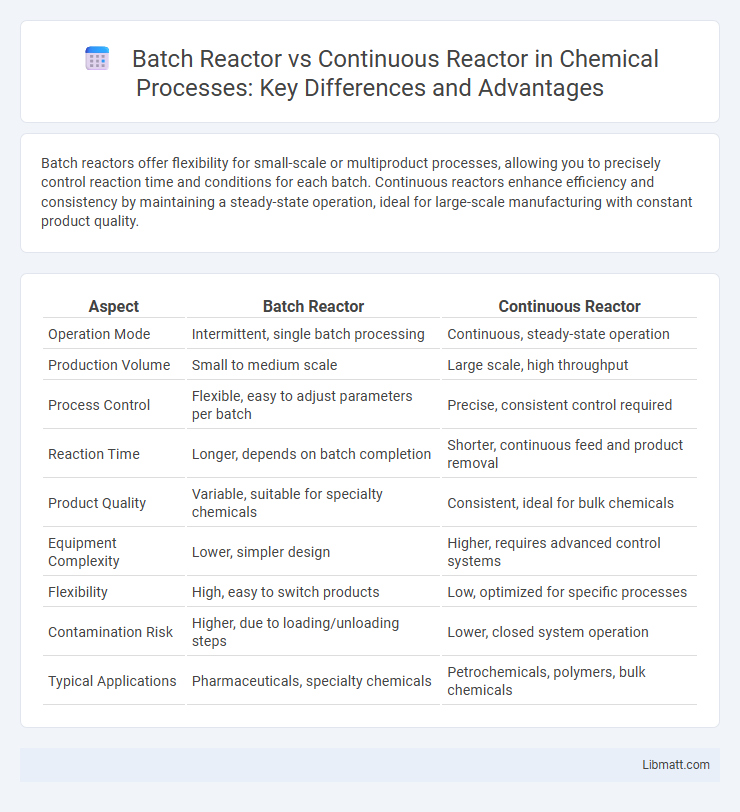

Batch reactors offer flexibility for small-scale or multiproduct processes, allowing you to precisely control reaction time and conditions for each batch. Continuous reactors enhance efficiency and consistency by maintaining a steady-state operation, ideal for large-scale manufacturing with constant product quality.

Table of Comparison

| Aspect | Batch Reactor | Continuous Reactor |

|---|---|---|

| Operation Mode | Intermittent, single batch processing | Continuous, steady-state operation |

| Production Volume | Small to medium scale | Large scale, high throughput |

| Process Control | Flexible, easy to adjust parameters per batch | Precise, consistent control required |

| Reaction Time | Longer, depends on batch completion | Shorter, continuous feed and product removal |

| Product Quality | Variable, suitable for specialty chemicals | Consistent, ideal for bulk chemicals |

| Equipment Complexity | Lower, simpler design | Higher, requires advanced control systems |

| Flexibility | High, easy to switch products | Low, optimized for specific processes |

| Contamination Risk | Higher, due to loading/unloading steps | Lower, closed system operation |

| Typical Applications | Pharmaceuticals, specialty chemicals | Petrochemicals, polymers, bulk chemicals |

Introduction to Batch and Continuous Reactors

Batch reactors operate by processing reactants in a single, closed system for a specific time, ideal for small-scale or variable production. Continuous reactors continuously feed reactants and remove products, supporting large-scale and consistent manufacturing. Selection depends on factors like reaction time, product uniformity, and production volume requirements.

Fundamental Principles of Batch Reactors

Batch reactors operate on the principle of processing a fixed volume of reactants in a closed vessel for a set period, enabling precise control over reaction time and conditions. These reactors are ideal for small-scale production, where flexibility and versatility in handling various reactions are essential. Your choice of batch reactors allows for thorough mixing and uniform temperature distribution, crucial for consistent product quality in complex chemical processes.

Key Features of Continuous Reactors

Continuous reactors operate under steady-state conditions, allowing for constant input and output of reactants and products, which enhances process efficiency and scalability. They provide precise control over reaction parameters such as temperature, pressure, and residence time, improving product consistency and yield. Common types include plug flow reactors and continuous stirred-tank reactors, widely used in large-scale chemical manufacturing and pharmaceutical production.

Comparative Advantages of Batch Reactors

Batch reactors offer precise control over reaction time, temperature, and mixing, making them ideal for small-scale production and complex chemical syntheses. They provide flexibility for developing new products and handling multiple reactions without cross-contamination. Their ability to accommodate variable batch sizes enhances cost-effectiveness in pharmaceutical, specialty chemical, and research applications.

Pros and Cons of Continuous Reactors

Continuous reactors offer higher efficiency and consistent product quality due to steady-state operation, making them ideal for large-scale chemical manufacturing. They provide better heat and mass transfer control, reducing reaction times and enhancing safety by minimizing hazardous intermediate accumulation. However, continuous reactors require significant upfront investment and complex control systems, limiting their flexibility for small or batch production runs.

Operational Differences Between Batch and Continuous Systems

Batch reactors operate in distinct time intervals, processing one batch at a time with clear start and stop phases, allowing for flexible handling of varying product formulations. Continuous reactors maintain steady-state conditions, enabling uninterrupted feed and product flow, which increases efficiency for large-scale production and uniform product quality. The operational differences center on control complexity, with batch reactors requiring more manual intervention and continuous reactors relying on automated systems for precise parameter regulation.

Scalability and Flexibility in Reactors

Batch reactors offer high flexibility for small-scale production and process development, allowing easy adjustments to reaction conditions. Continuous reactors excel in scalability, enabling consistent large-scale manufacturing with efficient heat and mass transfer. Your choice depends on the balance between production volume needs and process adaptability.

Industrial Applications: Batch vs Continuous

Batch reactors are predominantly used in pharmaceutical, specialty chemicals, and small-scale production where flexibility and precise control over reaction time and conditions are essential. Continuous reactors dominate large-scale industrial applications such as petrochemicals, polymers, and bulk chemical manufacturing due to their efficiency, consistent product quality, and scalability. The choice between batch and continuous reactors impacts cost-effectiveness, process control, and production volume in industrial operations.

Economic and Energy Considerations

Batch reactors generally incur higher operational costs due to periodic downtime for loading, unloading, and cleaning, while continuous reactors offer improved economic efficiency through steady-state operation and higher throughput. Energy consumption in batch reactors tends to be less optimized because heating and cooling cycles must restart each batch, whereas continuous reactors maintain consistent thermal profiles, reducing energy waste. Your choice between these reactors should weigh the balance of startup costs, production scale, and energy utilization to optimize economic and energy performance.

Choosing the Right Reactor: Factors to Consider

Selecting the right reactor depends on scale, process control, and production goals; batch reactors offer flexibility for small-scale or multi-product operations, while continuous reactors excel in large-scale, steady-state manufacturing with consistent quality. Consider reaction time, heat transfer efficiency, and catalyst compatibility to optimize yield and cost-effectiveness. Your choice impacts operational complexity, maintenance, and scalability, making thorough evaluation essential for process optimization.

Batch reactor vs continuous reactor Infographic

libmatt.com

libmatt.com