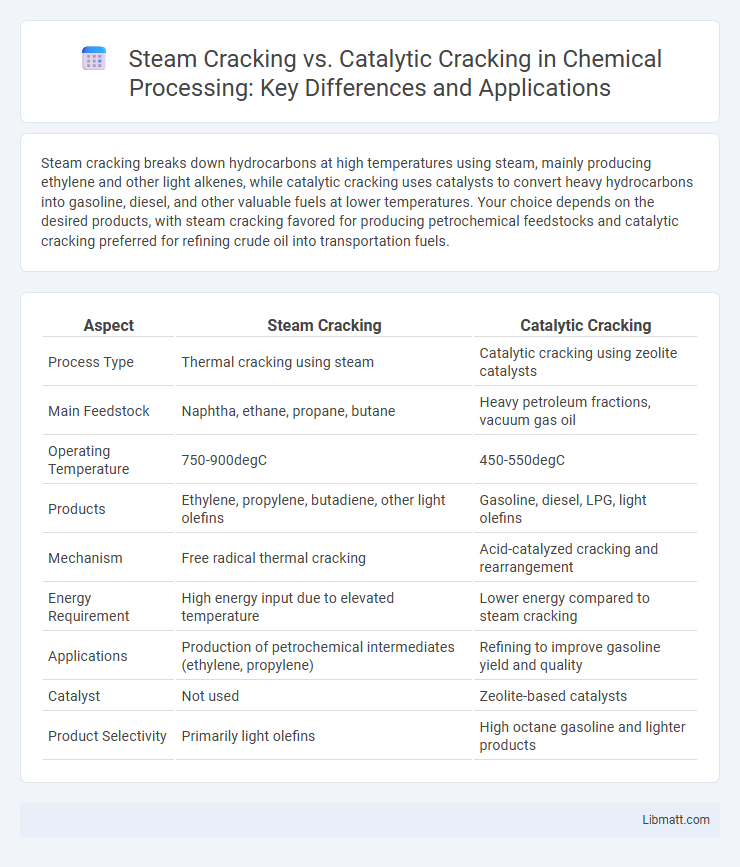

Steam cracking breaks down hydrocarbons at high temperatures using steam, mainly producing ethylene and other light alkenes, while catalytic cracking uses catalysts to convert heavy hydrocarbons into gasoline, diesel, and other valuable fuels at lower temperatures. Your choice depends on the desired products, with steam cracking favored for producing petrochemical feedstocks and catalytic cracking preferred for refining crude oil into transportation fuels.

Table of Comparison

| Aspect | Steam Cracking | Catalytic Cracking |

|---|---|---|

| Process Type | Thermal cracking using steam | Catalytic cracking using zeolite catalysts |

| Main Feedstock | Naphtha, ethane, propane, butane | Heavy petroleum fractions, vacuum gas oil |

| Operating Temperature | 750-900degC | 450-550degC |

| Products | Ethylene, propylene, butadiene, other light olefins | Gasoline, diesel, LPG, light olefins |

| Mechanism | Free radical thermal cracking | Acid-catalyzed cracking and rearrangement |

| Energy Requirement | High energy input due to elevated temperature | Lower energy compared to steam cracking |

| Applications | Production of petrochemical intermediates (ethylene, propylene) | Refining to improve gasoline yield and quality |

| Catalyst | Not used | Zeolite-based catalysts |

| Product Selectivity | Primarily light olefins | High octane gasoline and lighter products |

Introduction to Steam Cracking and Catalytic Cracking

Steam cracking is a high-temperature process used primarily to produce ethylene and other light olefins by breaking down hydrocarbons such as ethane and naphtha in the absence of a catalyst. Catalytic cracking utilizes a solid acid catalyst, typically zeolites, to convert heavy hydrocarbon fractions into gasoline, diesel, and valuable petrochemical feedstocks at lower temperatures than steam cracking. Both methods play essential roles in the petrochemical industry, optimizing the yield and quality of various hydrocarbon products through distinct mechanisms and conditions.

Historical Development of Cracking Processes

Steam cracking emerged in the early 20th century as a method to produce ethylene and other light olefins by thermally breaking down hydrocarbons at high temperatures without catalysts, revolutionizing the petrochemical industry. Catalytic cracking, developed in the 1930s, introduced catalysts to lower operating temperatures and increase the yield of gasoline and valuable aromatic hydrocarbons, significantly enhancing refinery efficiency. Both processes advanced in parallel, with steam cracking dominating olefin production and catalytic cracking optimizing fuel yields, shaping modern hydrocarbon processing technology.

Fundamental Principles of Steam Cracking

Steam cracking operates by thermally decomposing hydrocarbons at high temperatures (750-900degC) in the presence of steam, inducing free radical reactions that break large hydrocarbon molecules into smaller alkenes like ethylene and propylene. It relies on rapid quenching to stop reactions and maximize yield of unsaturated hydrocarbons, distinguishing it from catalytic cracking which uses a catalyst at lower temperatures to produce mainly gasoline-range hydrocarbons. The fundamental principle involves non-catalytic, endothermic cracking of saturated hydrocarbons, emphasizing temperature control and steam dilution to prevent coke formation and optimize olefin production.

Core Mechanisms in Catalytic Cracking

Catalytic cracking operates through the use of solid catalysts, typically zeolites, which facilitate the breaking of large hydrocarbon molecules into smaller, more valuable products like gasoline and olefins. The core mechanism involves protonation of hydrocarbons, generating carbocations that rearrange and cleave into lighter fractions under acidic conditions. Your refinery efficiency improves with catalytic cracking as it offers greater control over the reaction pathways and reduces energy consumption compared to steam cracking.

Feedstock Requirements and Versatility

Steam cracking primarily uses light hydrocarbon feedstocks such as ethane, propane, and naphtha, optimizing them for high yields of ethylene and propylene. Catalytic cracking processes heavier feedstocks like vacuum gas oil or residuum, enabling enhanced conversion of heavy fractions into valuable gasoline and olefins. The versatility of catalytic cracking accommodates a broader range of feedstocks, while steam cracking focuses on lighter inputs for targeted olefin production.

Product Yields and Distribution

Steam cracking primarily produces light olefins such as ethylene and propylene with high yields, making it ideal for petrochemical feedstock production. Catalytic cracking yields a higher proportion of gasoline-range hydrocarbons and aromatic compounds, optimizing fuel output. Your choice depends on whether the goal is maximizing light olefins or gasoline-range products.

Process Conditions and Reactor Design

Steam cracking operates at extremely high temperatures around 750-900degC in tubular reactors with short residence times, optimizing ethylene and propylene yields. Catalytic cracking uses lower temperatures (450-550degC) in a fluidized bed reactor with a catalyst to break down heavy hydrocarbons into gasoline-range products. Your choice of process depends on feedstock and product goals, influencing reactor design and operating conditions significantly.

Environmental Impact and Energy Efficiency

Steam cracking consumes high amounts of energy due to the requirement of extremely high temperatures, resulting in significant CO2 emissions and a larger carbon footprint compared to catalytic cracking. Catalytic cracking operates at lower temperatures with catalysts, enhancing energy efficiency and reducing greenhouse gas emissions, making it a more environmentally-friendly option. The choice between these processes impacts refinery sustainability, as catalytic cracking aligns better with reducing fossil fuel consumption and mitigating environmental pollution.

Industrial Applications and Market Relevance

Steam cracking is predominantly used in the petrochemical industry for producing ethylene, propylene, and other light olefins, essential feedstocks for plastics and synthetic materials, driving its major market demand. Catalytic cracking plays a critical role in refining heavier crude oil fractions into valuable gasoline, diesel, and jet fuel, maintaining its strong relevance in the global fuel market. Your choice between these processes depends on targeted products and industry applications, with steam cracking favored for olefin production and catalytic cracking optimized for fuel generation.

Future Trends and Technological Innovations

Steam cracking advancements focus on enhancing energy efficiency and reducing CO2 emissions through the integration of renewable hydrogen and electrification technologies, enabling sustainable production of ethylene and propylene. Catalytic cracking innovations emphasize the development of novel zeolite catalysts and microwave-assisted processes to improve yield selectivity and lower operational costs in producing high-octane gasoline and petrochemical feedstocks. Future trends include digitalization with AI-driven process optimization and real-time monitoring systems to maximize throughput and minimize environmental impact across both cracking methodologies.

Steam cracking vs catalytic cracking Infographic

libmatt.com

libmatt.com