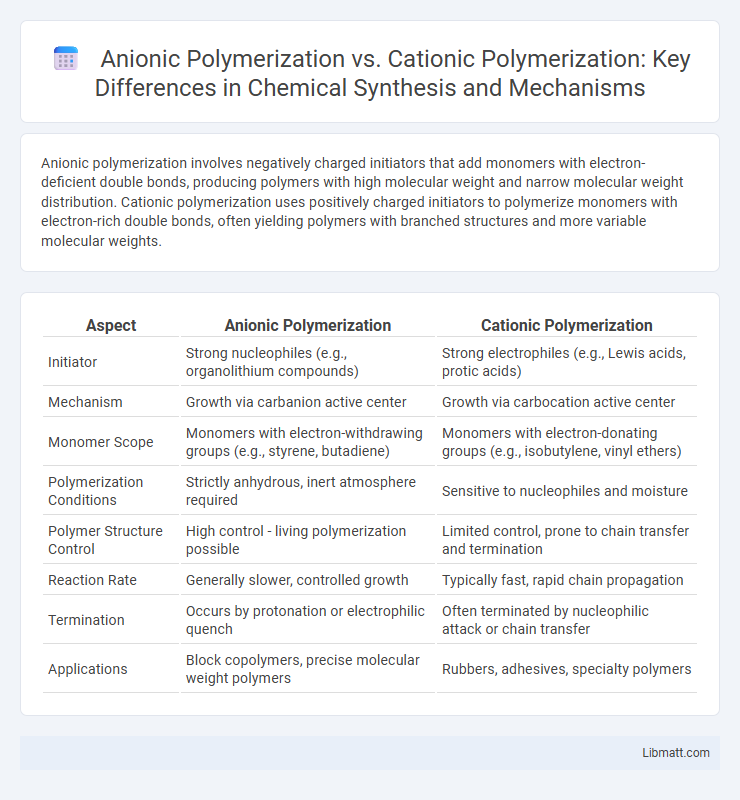

Anionic polymerization involves negatively charged initiators that add monomers with electron-deficient double bonds, producing polymers with high molecular weight and narrow molecular weight distribution. Cationic polymerization uses positively charged initiators to polymerize monomers with electron-rich double bonds, often yielding polymers with branched structures and more variable molecular weights.

Table of Comparison

| Aspect | Anionic Polymerization | Cationic Polymerization |

|---|---|---|

| Initiator | Strong nucleophiles (e.g., organolithium compounds) | Strong electrophiles (e.g., Lewis acids, protic acids) |

| Mechanism | Growth via carbanion active center | Growth via carbocation active center |

| Monomer Scope | Monomers with electron-withdrawing groups (e.g., styrene, butadiene) | Monomers with electron-donating groups (e.g., isobutylene, vinyl ethers) |

| Polymerization Conditions | Strictly anhydrous, inert atmosphere required | Sensitive to nucleophiles and moisture |

| Polymer Structure Control | High control - living polymerization possible | Limited control, prone to chain transfer and termination |

| Reaction Rate | Generally slower, controlled growth | Typically fast, rapid chain propagation |

| Termination | Occurs by protonation or electrophilic quench | Often terminated by nucleophilic attack or chain transfer |

| Applications | Block copolymers, precise molecular weight polymers | Rubbers, adhesives, specialty polymers |

Introduction to Polymerization Techniques

Anionic polymerization involves the initiation of polymer chains through negatively charged species, enabling precise control over molecular weight and architecture, while cationic polymerization uses positively charged initiators to propagate polymer growth. Both techniques are essential in synthesizing polymers with distinct properties, such as improved thermal stability or elasticity, tailored to specific applications. Understanding your choice between anionic and cationic methods is critical for achieving desired polymer characteristics in advanced material design.

Overview of Anionic Polymerization

Anionic polymerization is a type of chain-growth polymerization characterized by the initiation of polymer chains through negatively charged ions, typically using organometallic compounds or alkali metals as initiators. This method allows precise control over molecular weight and polymer architecture, enabling the synthesis of polymers with narrow molecular weight distributions and well-defined block copolymers. Your understanding of this process highlights its key advantages in producing polymers for applications requiring high purity and uniformity, such as specialty elastomers and advanced materials.

Overview of Cationic Polymerization

Cationic polymerization involves the initiation of polymer chains through positively charged ions, typically using Lewis acids or protonic acids as catalysts. The process is highly effective for monomers containing electron-rich double bonds, such as isobutylene and vinyl ethers, facilitating rapid chain propagation with controlled molecular weights. Your ability to tailor polymer properties depends on the stability of the carbocation intermediates and reaction conditions like temperature and solvent polarity.

Key Differences Between Anionic and Cationic Polymerization

Anionic polymerization involves negatively charged initiators creating reactive anions, while cationic polymerization uses positively charged initiators forming reactive cations. Anionic polymerization typically operates under rigorously controlled conditions with high sensitivity to impurities, leading to living polymer chains and narrow molecular weight distributions. Cationic polymerization often proceeds rapidly at moderate conditions with broader molecular weight distribution and is more tolerant to impurities but prone to chain transfer reactions.

Mechanisms of Anionic Polymerization

Anionic polymerization involves the growth of polymer chains initiated by negatively charged species, typically nucleophiles such as organolithium compounds, which attack electrophilic monomers with electron-deficient double bonds. The mechanism proceeds through a reactive carbanion intermediate that adds monomer units in a chain-growth process without termination or chain transfer under ideal conditions, enabling precise control over molecular weight and polymer architecture. This living polymerization technique allows for the synthesis of block copolymers and narrow molecular weight distributions due to the stability of the anionic active centers throughout the reaction.

Mechanisms of Cationic Polymerization

Cationic polymerization proceeds via the formation of a positively charged carbocation intermediate, which initiates the chain growth by successive addition of monomer units with electron-rich double bonds. This mechanism relies heavily on the stability of the carbocation, influenced by resonance and inductive effects, as well as the presence of counterions that help balance the charge. Your understanding of the distinct steps--initiation, propagation, and termination--in this electrophilic polymerization process is crucial for controlling polymer architecture and molecular weight.

Suitable Monomers for Each Method

Anionic polymerization is suitable for monomers with electron-withdrawing groups such as styrene, butadiene, and methyl methacrylate, which stabilize the negative charge during polymer chain growth. Cationic polymerization favors monomers with electron-donating groups like isobutylene, vinyl ethers, and N-vinyl carbazole, enabling the formation of positively charged carbocations for propagation. Your understanding of these monomer characteristics is essential for selecting the appropriate polymerization technique to achieve desired polymer properties.

Advantages and Limitations

Anionic polymerization offers precise control over molecular weight and polymer architecture, making it ideal for synthesizing block copolymers and polymers with narrow molecular weight distributions. Its limitations include sensitivity to impurities and moisture, which can inhibit initiation and propagation steps. Cationic polymerization allows rapid polymerization of vinyl ethers and styrenes but faces challenges with chain transfer and termination reactions, resulting in broader molecular weight distributions and less control over polymer structure.

Industrial Applications and Case Studies

Anionic polymerization is widely utilized in the production of synthetic rubber, such as styrene-butadiene rubber (SBR), delivering materials with high molecular weight and narrow molecular weight distribution essential for tire manufacturing. Cationic polymerization finds extensive industrial application in producing polymers like polystyrene and polyisobutylene, key components in adhesives, sealants, and fuel additives, where control over polymer branching and molecular structure is crucial. Your choice between these polymerization methods depends on the desired polymer properties and industrial application, with numerous case studies highlighting the optimization of reaction conditions to enhance product performance and economic viability.

Future Trends in Anionic and Cationic Polymerization

Future trends in anionic and cationic polymerization emphasize advancements in controlled/living polymerization techniques to achieve precise molecular architectures and narrow molecular weight distributions. Innovations in catalyst design and reaction conditions aim to enhance polymerization efficiency and enable sustainable, scalable processes for specialty polymers used in electronics, biomedical applications, and high-performance materials. Your ability to tailor polymer properties through these evolving polymerization methods will drive next-generation material development in various industrial sectors.

Anionic polymerization vs cationic polymerization Infographic

libmatt.com

libmatt.com