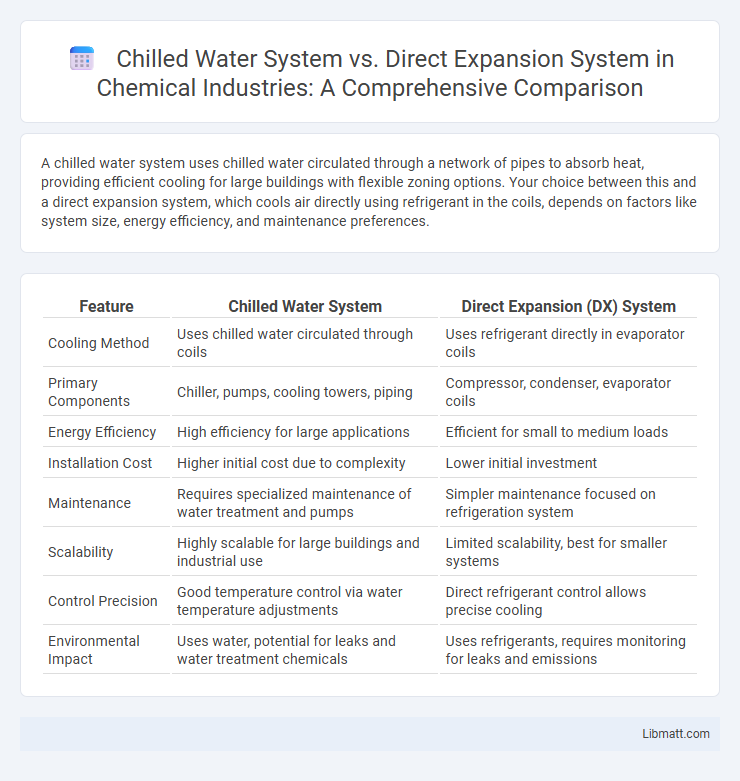

A chilled water system uses chilled water circulated through a network of pipes to absorb heat, providing efficient cooling for large buildings with flexible zoning options. Your choice between this and a direct expansion system, which cools air directly using refrigerant in the coils, depends on factors like system size, energy efficiency, and maintenance preferences.

Table of Comparison

| Feature | Chilled Water System | Direct Expansion (DX) System |

|---|---|---|

| Cooling Method | Uses chilled water circulated through coils | Uses refrigerant directly in evaporator coils |

| Primary Components | Chiller, pumps, cooling towers, piping | Compressor, condenser, evaporator coils |

| Energy Efficiency | High efficiency for large applications | Efficient for small to medium loads |

| Installation Cost | Higher initial cost due to complexity | Lower initial investment |

| Maintenance | Requires specialized maintenance of water treatment and pumps | Simpler maintenance focused on refrigeration system |

| Scalability | Highly scalable for large buildings and industrial use | Limited scalability, best for smaller systems |

| Control Precision | Good temperature control via water temperature adjustments | Direct refrigerant control allows precise cooling |

| Environmental Impact | Uses water, potential for leaks and water treatment chemicals | Uses refrigerants, requires monitoring for leaks and emissions |

Introduction to Chilled Water and Direct Expansion Systems

Chilled water systems use a centralized chiller to cool water, which is then circulated through air handling units or fan coil units to absorb heat from the building. Direct expansion (DX) systems cool air directly by compressing and expanding refrigerant within the coils of air handling units, eliminating the need for water as a medium. Your choice between chilled water and DX systems depends on factors like building size, cooling load, and energy efficiency requirements.

Basic Working Principles Explained

Chilled water systems circulate cooled water through a network of pipes to absorb and remove heat from indoor air via air handling units or fan coil units, relying on a central chiller to lower water temperature. Direct expansion (DX) systems use refrigerant circulated directly through evaporator coils in air handlers, where it absorbs heat from the indoor air before being compressed and cooled again externally. The key difference lies in the heat exchange medium, with chilled water systems using water as an intermediary and DX systems utilizing refrigerant for direct cooling.

Key Components of Each System

A chilled water system primarily consists of chillers, cooling towers, pumps, air handling units (AHUs), and a network of insulated pipes circulating chilled water throughout the building. In contrast, a direct expansion (DX) system incorporates a refrigerant-based compressor, condenser, expansion valve, and evaporator coil within each air handling unit or terminal, eliminating the need for chilled water circulation. Both systems utilize thermostats and control valves to regulate temperature, but the chilled water system relies on secondary fluid transport, while the DX system operates through direct refrigerant expansion at the cooling coil.

Energy Efficiency Comparison

Chilled water systems offer higher energy efficiency for large-scale cooling applications due to centralized chillers and optimized load distribution, reducing overall power consumption. Direct expansion (DX) systems tend to have lower initial costs but can be less energy-efficient in variable load conditions because each unit operates independently without load sharing. Your choice impacts energy savings significantly, with chilled water systems often outperforming DX systems in efficiency for commercial and industrial settings.

Initial Installation Costs

Chilled water systems generally have higher initial installation costs due to the complexity of components like chillers, pumps, and extensive piping networks. Direct expansion (DX) systems typically require less equipment and simpler installation, making them more cost-effective upfront for smaller or less complex applications. Your choice should consider budget constraints alongside long-term efficiency and maintenance expenses.

Maintenance Requirements and Costs

Chilled water systems generally require more extensive maintenance due to their complex network of pumps, pipes, and cooling towers, leading to higher maintenance costs compared to direct expansion (DX) systems. DX systems have simpler components with fewer moving parts, resulting in lower routine maintenance needs and reduced service expenses. Your choice between these systems should consider long-term maintenance budgets and available technical expertise.

Application Suitability: Commercial vs Residential

Chilled water systems are highly suitable for large commercial buildings due to their efficiency in cooling extensive spaces and ability to integrate with centralized HVAC controls. Direct expansion (DX) systems are more appropriate for residential applications, offering simpler installation and lower upfront costs for smaller cooling loads. Commercial settings benefit from chilled water systems' scalability and energy savings, while DX systems provide effective, localized cooling for homes.

Space and Design Flexibility

Chilled water systems offer greater design flexibility by allowing the use of smaller, decentralized air handling units, which can be strategically placed to optimize space utilization in large buildings. Direct expansion systems typically require larger equipment units and dedicated space near the conditioned area, limiting placement options and restricting interior design choices. Your project benefits from chilled water solutions when complex layouts demand adaptable installation without compromising usable floor space.

Environmental Impact and Sustainability

A chilled water system typically offers greater environmental sustainability due to its ability to use centralized cooling plants that can incorporate energy-efficient chillers and leverage renewable energy sources, reducing overall carbon emissions. In contrast, direct expansion (DX) systems generally consume more electricity per unit of cooling because each unit operates independently, often leading to higher greenhouse gas emissions. Your choice of a chilled water system can significantly contribute to long-term energy savings and lower environmental impact, making it a more eco-friendly option for large-scale cooling applications.

Final Verdict: Choosing the Right Cooling System

Chilled water systems deliver precise temperature control and energy efficiency for large commercial buildings by circulating chilled water through air handling units, making them ideal for extensive cooling demands. Direct expansion (DX) systems provide simpler installation and cost-effective cooling for smaller spaces by directly expanding refrigerant in the evaporator coil. Selecting the right cooling system depends on building size, energy efficiency goals, installation complexity, and operational costs, with chilled water favored for large-scale HVAC applications and DX preferred for compact or budget-conscious projects.

Chilled water system vs direct expansion system Infographic

libmatt.com

libmatt.com