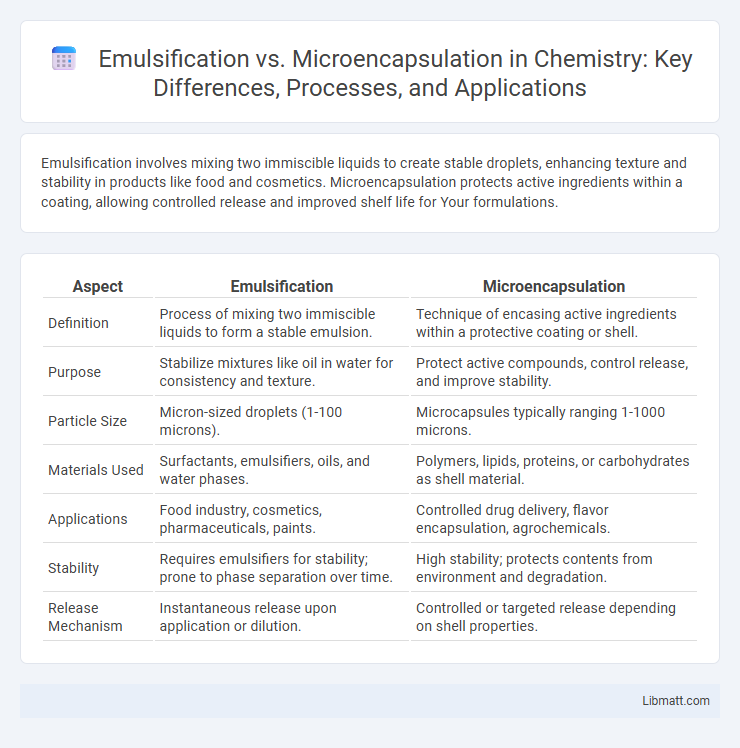

Emulsification involves mixing two immiscible liquids to create stable droplets, enhancing texture and stability in products like food and cosmetics. Microencapsulation protects active ingredients within a coating, allowing controlled release and improved shelf life for Your formulations.

Table of Comparison

| Aspect | Emulsification | Microencapsulation |

|---|---|---|

| Definition | Process of mixing two immiscible liquids to form a stable emulsion. | Technique of encasing active ingredients within a protective coating or shell. |

| Purpose | Stabilize mixtures like oil in water for consistency and texture. | Protect active compounds, control release, and improve stability. |

| Particle Size | Micron-sized droplets (1-100 microns). | Microcapsules typically ranging 1-1000 microns. |

| Materials Used | Surfactants, emulsifiers, oils, and water phases. | Polymers, lipids, proteins, or carbohydrates as shell material. |

| Applications | Food industry, cosmetics, pharmaceuticals, paints. | Controlled drug delivery, flavor encapsulation, agrochemicals. |

| Stability | Requires emulsifiers for stability; prone to phase separation over time. | High stability; protects contents from environment and degradation. |

| Release Mechanism | Instantaneous release upon application or dilution. | Controlled or targeted release depending on shell properties. |

Introduction to Emulsification and Microencapsulation

Emulsification is a process that disperses one liquid into another immiscible liquid, forming stable droplets essential in food, pharmaceuticals, and cosmetics industries. Microencapsulation involves enclosing active ingredients within a protective coating to enhance stability, control release, and mask flavors in products like supplements and agrochemicals. Understanding these techniques helps you optimize formulation strategies for improved product performance and shelf life.

Defining Emulsification: Principles and Processes

Emulsification involves the dispersion of two immiscible liquids, typically oil and water, into a stable mixture through mechanical agitation and the use of emulsifiers that reduce surface tension between the phases. This process creates emulsions with droplet sizes generally ranging from 0.1 to 100 microns, enhancing the bioavailability and stability of active compounds in food, pharmaceuticals, and cosmetics. Your understanding of emulsification's principles is essential for selecting appropriate emulsifiers and process conditions to achieve desired texture, consistency, and functional performance.

Understanding Microencapsulation: Key Concepts

Microencapsulation involves enclosing active ingredients within a micro-scale coating to protect them from environmental factors and control their release, differing from emulsification which disperses one liquid phase into another. Key concepts of microencapsulation include the choice of core and wall materials, encapsulation efficiency, and release mechanisms such as diffusion, dissolution, or rupture. This technology finds applications across pharmaceuticals, food industries, and cosmetics for targeted delivery and enhanced stability of sensitive compounds.

Core Differences: Emulsification vs Microencapsulation

Emulsification involves dispersing one liquid into another immiscible liquid to create a stable mixture, primarily focusing on forming droplets of oil in water or vice versa. Microencapsulation, in contrast, encloses active ingredients or particles within a protective coating, allowing for controlled release and enhanced stability. The core difference lies in emulsification producing a dispersed phase within a carrier liquid, while microencapsulation creates discrete capsules that isolate the core material from the external environment.

Applications in Food and Pharmaceutical Industries

Emulsification creates stable mixtures of immiscible liquids and is widely used in the food industry for products like salad dressings and sauces, enhancing texture and flavor release. Microencapsulation involves enclosing active ingredients within a protective coating, offering controlled release and improved stability for pharmaceuticals such as vitamins and probiotics. Understanding these techniques enables you to select the best method for targeted delivery and preservation of sensitive bioactives in both food and pharmaceutical formulations.

Advantages of Emulsification

Emulsification offers enhanced bioavailability by improving the solubility and controlled release of hydrophobic compounds, making it ideal for food, pharmaceutical, and cosmetic applications. This technique provides cost-effective scalability and flexibility in formulation, allowing for the incorporation of various active ingredients into stable oil-in-water or water-in-oil systems. Emulsification also ensures higher stability against environmental factors such as pH, temperature, and oxidation, prolonging the shelf life and efficacy of the encapsulated substances.

Benefits of Microencapsulation

Microencapsulation offers enhanced stability and controlled release of active ingredients compared to emulsification, protecting sensitive compounds from environmental factors such as oxidation, moisture, and light. This technique improves bioavailability and allows for targeted delivery in pharmaceuticals, food, and cosmetics, ensuring prolonged efficacy and reduced degradation. Additionally, microencapsulation enables masking of unpleasant flavors and odors, improving consumer acceptability and product performance.

Limitations and Challenges of Each Technique

Emulsification faces challenges such as limited stability due to droplet coalescence and sensitivity to environmental factors like temperature and pH, which can compromise encapsulated ingredient integrity. Microencapsulation encounters limitations including complex processing requirements, higher production costs, and potential difficulties in controlling release rates and particle size uniformity. Understanding these constraints helps you select the most appropriate method for your specific application needs.

Selection Criteria: When to Use Emulsification or Microencapsulation

Selection criteria for emulsification versus microencapsulation depend on the desired particle size, stability, and release profile of active ingredients. Emulsification is ideal for creating oil-in-water or water-in-oil dispersions with droplet sizes typically ranging from micrometers to nanometers, suitable for applications requiring immediate or controlled release of bioactive compounds. Microencapsulation offers enhanced protection and targeted delivery by enclosing ingredients within a polymeric shell, making it preferable when Your product demands prolonged stability, masking of flavors, or controlled release in pharmaceuticals, food, or cosmetics.

Future Trends in Emulsion and Encapsulation Technologies

Future trends in emulsion and encapsulation technologies emphasize the development of smart and stimuli-responsive delivery systems that improve targeted release and bioavailability. Innovations in nanoemulsion and advanced microencapsulation techniques enable precise control over particle size, stability, and encapsulation efficiency, fostering applications in pharmaceuticals, food, and cosmetics. Integration of sustainable, biodegradable materials and green processing methods is driving eco-friendly advancements in these technologies.

Emulsification vs microencapsulation Infographic

libmatt.com

libmatt.com