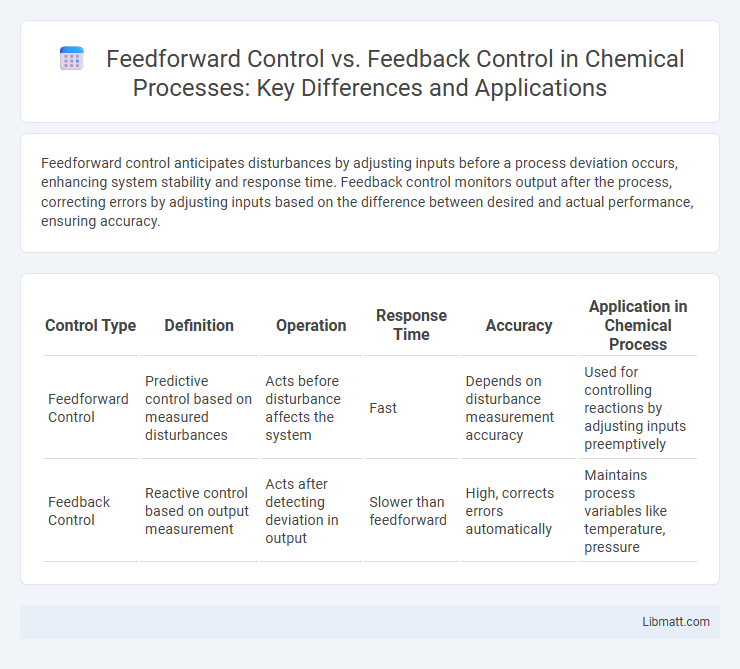

Feedforward control anticipates disturbances by adjusting inputs before a process deviation occurs, enhancing system stability and response time. Feedback control monitors output after the process, correcting errors by adjusting inputs based on the difference between desired and actual performance, ensuring accuracy.

Table of Comparison

| Control Type | Definition | Operation | Response Time | Accuracy | Application in Chemical Process |

|---|---|---|---|---|---|

| Feedforward Control | Predictive control based on measured disturbances | Acts before disturbance affects the system | Fast | Depends on disturbance measurement accuracy | Used for controlling reactions by adjusting inputs preemptively |

| Feedback Control | Reactive control based on output measurement | Acts after detecting deviation in output | Slower than feedforward | High, corrects errors automatically | Maintains process variables like temperature, pressure |

Introduction to Feedforward and Feedback Control

Feedforward control anticipates disturbances by adjusting inputs based on measured or predicted changes before they affect the system, while feedback control reacts to errors by correcting deviations from the desired output after they occur. Your system's stability and responsiveness improve with a strategic combination of feedforward control for proactive adjustment and feedback control for error correction. Implementing both controls optimizes performance by balancing prediction and reaction in dynamic environments.

Key Concepts of Feedforward Control

Feedforward control anticipates disturbances by measuring variables before they affect the system, allowing corrective actions to be applied proactively. Unlike feedback control, which reacts to errors after they occur, feedforward control relies on models and external inputs to maintain desired performance. Your system's stability and responsiveness improve significantly when feedforward control integrates accurate predictive data to minimize deviations.

Key Concepts of Feedback Control

Feedback control operates by continuously monitoring system outputs and comparing them to desired setpoints to detect deviations. It relies on closed-loop mechanisms where corrective actions are applied based on error signals to maintain system stability. Key components include sensors, controllers, and actuators that work together to adjust inputs and minimize the difference between actual and target performance.

Major Differences Between Feedforward and Feedback Control

Feedforward control anticipates disturbances and adjusts the system input proactively, whereas feedback control reacts to deviations by correcting errors after they occur. Feedforward control requires an accurate model of the process and disturbance variables, while feedback control relies on real-time output measurements to maintain desired performance. Your choice between these methods depends on the need for speed in response and availability of system information.

Advantages of Feedforward Control Systems

Feedforward control systems excel in providing rapid response by anticipating disturbances before they affect the process, enabling preemptive adjustments that minimize error and enhance stability. These systems reduce reliance on corrective actions typical in feedback control, improving overall system efficiency and reducing oscillations or time delays. Feedforward control is particularly advantageous in environments with predictable disturbance patterns, ensuring continuous optimal performance without waiting for output deviations.

Advantages of Feedback Control Systems

Feedback control systems offer robust compensation for disturbances by continuously monitoring output and adjusting inputs to maintain desired performance. They enhance system stability and accuracy by reducing errors caused by unpredicted changes or external interference. This adaptability ensures consistent operation in dynamic environments, making feedback control essential for complex, real-time process regulation.

Limitations of Feedforward Control

Feedforward control is limited by its reliance on accurate models and predictable disturbances, making it ineffective against unforeseen changes or system noise. It cannot correct errors after they occur, which often necessitates integration with feedback control to ensure system stability and performance. Complex systems with nonlinearities or time delays pose additional challenges for feedforward control accuracy.

Limitations of Feedback Control

Feedback control systems often experience delayed responses due to the time required for error detection and correction, limiting their effectiveness in rapidly changing environments. They can also amplify noise and disturbances, leading to oscillations or instability if the system parameters are not properly tuned. Moreover, feedback control cannot prevent errors but only correct them after they occur, which may result in reduced overall system efficiency.

Applications in Industry: Feedforward vs Feedback Control

Feedforward control is widely applied in industries where predictive adjustments are critical, such as chemical processing and automotive manufacturing, enabling systems to counteract disturbances before they affect output. Feedback control is essential in maintaining stability and accuracy in processes like temperature regulation and motor speed control by continuously correcting deviations from setpoints. Your choice between feedforward and feedback control depends on the need for proactive disturbance handling versus reactive error correction in industrial automation.

Choosing the Right Control Strategy for Your System

Feedforward control anticipates disturbances by adjusting inputs based on a model of the system, reducing response time and improving accuracy, while feedback control reacts to errors by continuously correcting deviations from the desired output. Your choice depends on factors like system dynamics, disturbance predictability, and available sensors, where feedforward excels in stable, predictable environments and feedback provides robust correction for unforeseen variations. Optimizing performance often involves combining both strategies to ensure precision and adaptability across varying operating conditions.

feedforward control vs feedback control Infographic

libmatt.com

libmatt.com