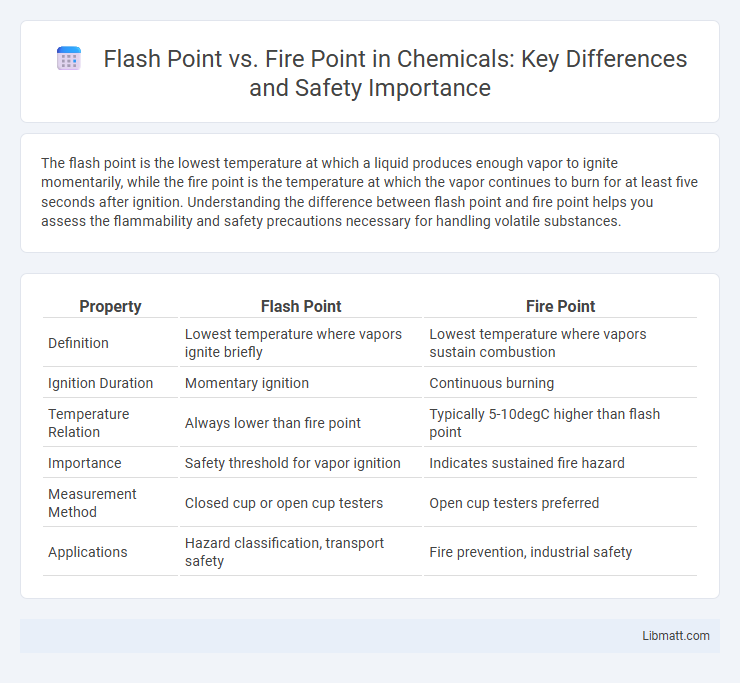

The flash point is the lowest temperature at which a liquid produces enough vapor to ignite momentarily, while the fire point is the temperature at which the vapor continues to burn for at least five seconds after ignition. Understanding the difference between flash point and fire point helps you assess the flammability and safety precautions necessary for handling volatile substances.

Table of Comparison

| Property | Flash Point | Fire Point |

|---|---|---|

| Definition | Lowest temperature where vapors ignite briefly | Lowest temperature where vapors sustain combustion |

| Ignition Duration | Momentary ignition | Continuous burning |

| Temperature Relation | Always lower than fire point | Typically 5-10degC higher than flash point |

| Importance | Safety threshold for vapor ignition | Indicates sustained fire hazard |

| Measurement Method | Closed cup or open cup testers | Open cup testers preferred |

| Applications | Hazard classification, transport safety | Fire prevention, industrial safety |

Understanding Flash Point and Fire Point

Flash point is the lowest temperature at which a liquid produces enough vapor to ignite momentarily when exposed to an ignition source, indicating flammability risk. Fire point occurs at a slightly higher temperature where the vapor sustains continuous combustion, reflecting a greater hazard level. Knowing the difference between flash point and fire point is crucial for safe handling and storage of flammable liquids in industrial and safety management contexts.

Definitions of Flash Point and Fire Point

The flash point is the lowest temperature at which a liquid produces enough vapor to ignite momentarily when exposed to a flame. The fire point is the temperature at which the vapor continues to burn for at least five seconds, indicating sustained combustion. Understanding the difference between your fuel's flash point and fire point is essential for safe handling and storage.

Key Differences Between Flash Point and Fire Point

Flash point is the lowest temperature at which a liquid produces enough vapor to form an ignitable mixture with air, while fire point is the temperature at which the liquid produces vapors that sustain combustion for at least five seconds. The flash point indicates the potential for vapor ignition, whereas the fire point reflects the ability of the fuel to maintain a continuous flame. Understanding these distinctions is crucial for assessing fire hazards and selecting appropriate safety measures in handling flammable substances.

Importance of Measuring Flash Point

Measuring the flash point is crucial for determining the lowest temperature at which a liquid emits enough vapor to ignite in the presence of an ignition source, providing vital data for safety and handling protocols. The flash point helps assess flammability risks, ensuring proper storage, transportation, and regulatory compliance for substances such as fuels, solvents, and chemicals. Accurate flash point measurement minimizes fire hazards, protecting personnel, property, and the environment in industrial and laboratory settings.

Significance of Determining Fire Point

Determining the fire point is crucial for assessing the safety and handling of flammable liquids, as it indicates the temperature at which a substance produces enough vapor to sustain combustion. Unlike the flash point, which only signals the temperature at which vapors ignite briefly, the fire point confirms continuous burning, providing essential data for fire hazard prevention. Understanding your material's fire point helps implement proper storage and safety measures, minimizing the risk of accidental fires.

Methods for Testing Flash Point

Flash point testing methods include the Pensky-Martens closed cup, commonly used for petroleum products, and the Cleveland open cup, suitable for oils with higher flash points. The Abel closed cup method is specifically designed for volatile petroleum products, providing precise measurements under controlled conditions. Each method follows standardized protocols such as ASTM D93, ASTM D56, or ISO 2719 to ensure accurate and consistent flash point determination.

Techniques for Assessing Fire Point

Techniques for assessing fire point include the Cleveland Open Cup and Pensky-Martens Closed Cup methods, which measure the temperature at which a liquid produces enough vapor to sustain combustion. Fire point testing involves gradually heating a liquid sample and applying an ignition source to determine the temperature where sustained burning occurs, providing critical safety data for handling flammable materials. Your choice of technique depends on the type of sample and industry standards to ensure accurate and reliable fire hazard assessments.

Factors Influencing Flash and Fire Points

Temperature, pressure, and the chemical composition of the liquid significantly influence flash point and fire point measurements. Volatile compounds with lower molecular weights tend to have lower flash points, while environmental factors such as airflow and humidity can alter ignition properties. Understanding these factors helps you accurately assess flammability risks in various substances.

Safety Implications in Industry

Flash point indicates the lowest temperature at which vapors of a flammable liquid ignite briefly, serving as a critical metric for assessing initial fire hazards in industrial environments. Fire point, higher than the flash point, marks the temperature at which vapors sustain combustion, providing essential information for safe handling, storage, and process design in chemical plants and refineries. Understanding both points enables industries to implement proper fire prevention measures, select appropriate firefighting equipment, and comply with regulatory standards to minimize the risk of fire-related accidents.

Flash Point vs Fire Point: Applications and Standards

Flash point and fire point are critical parameters in safety standards for handling flammable liquids, where the flash point indicates the lowest temperature at which vapors ignite momentarily, and the fire point is the temperature at which sustained combustion occurs. Industries rely on these measurements to classify materials under standards such as ASTM D93 and ISO 2719, ensuring proper storage, transport, and usage protocols to mitigate fire hazards. Your adherence to these applications and standards protects workplaces and complies with regulatory requirements in chemical processing, fuel management, and manufacturing sectors.

flash point vs fire point Infographic

libmatt.com

libmatt.com