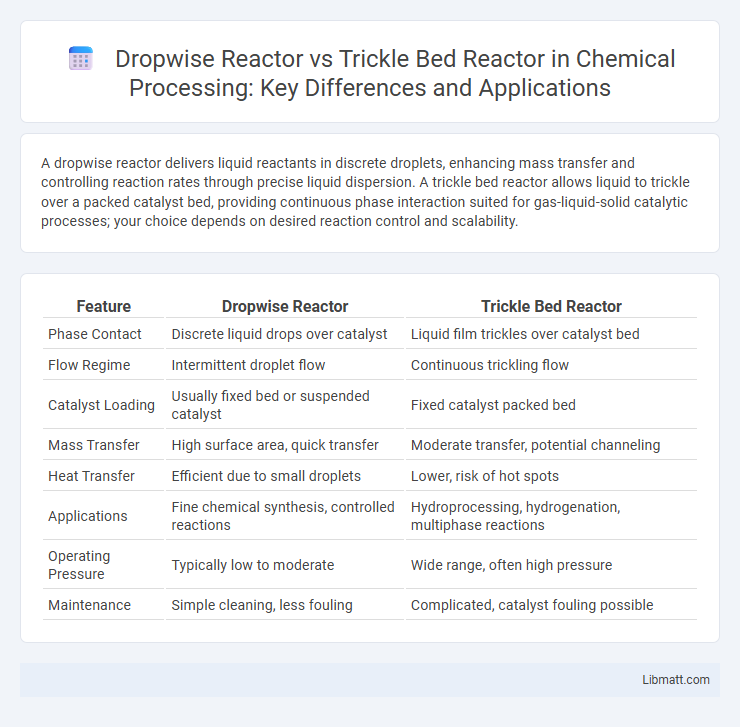

A dropwise reactor delivers liquid reactants in discrete droplets, enhancing mass transfer and controlling reaction rates through precise liquid dispersion. A trickle bed reactor allows liquid to trickle over a packed catalyst bed, providing continuous phase interaction suited for gas-liquid-solid catalytic processes; your choice depends on desired reaction control and scalability.

Table of Comparison

| Feature | Dropwise Reactor | Trickle Bed Reactor |

|---|---|---|

| Phase Contact | Discrete liquid drops over catalyst | Liquid film trickles over catalyst bed |

| Flow Regime | Intermittent droplet flow | Continuous trickling flow |

| Catalyst Loading | Usually fixed bed or suspended catalyst | Fixed catalyst packed bed |

| Mass Transfer | High surface area, quick transfer | Moderate transfer, potential channeling |

| Heat Transfer | Efficient due to small droplets | Lower, risk of hot spots |

| Applications | Fine chemical synthesis, controlled reactions | Hydroprocessing, hydrogenation, multiphase reactions |

| Operating Pressure | Typically low to moderate | Wide range, often high pressure |

| Maintenance | Simple cleaning, less fouling | Complicated, catalyst fouling possible |

Introduction to Dropwise and Trickle Bed Reactors

Dropwise reactors operate by allowing liquid to form discrete droplets that fall through a gas phase, maximizing gas-liquid contact and enhancing mass transfer rates. Trickle bed reactors involve a continuous liquid phase trickling over a packed bed of catalyst particles, promoting catalytic reactions with improved heat and mass transfer in fixed bed configurations. Your choice between the two depends on the specific reaction kinetics, catalyst type, and desired scale of operation.

Fundamental Principles of Dropwise Reactors

Dropwise reactors operate on the principle of catalyst particles suspended in a liquid phase, enabling efficient mass transfer and intimate contact between reactants and catalyst surfaces. This design facilitates superior heat management and uniform reactant distribution compared to trickle bed reactors, where liquid flows as thin films over catalyst pellets. Understanding these fundamental principles helps optimize your chemical reactions by enhancing catalytic performance and process control.

Key Features of Trickle Bed Reactors

Trickle bed reactors feature a fixed bed of catalyst particles where liquid and gas phases flow concurrently downward, enabling efficient mass transfer and excellent catalyst utilization. These reactors operate under moderate pressure and temperature, making them ideal for hydroprocessing and oxidation reactions in petrochemical and environmental applications. Their key advantages include simplified operation, enhanced reaction control, and the ability to handle multiphase flows with improved reaction selectivity and conversion rates compared to dropwise reactors.

Comparative Design and Configuration

Dropwise reactors feature discrete liquid droplets dispersed over a catalyst surface, enabling enhanced gas-liquid contact with minimal liquid holdup, typically designed for fine-tuned catalytic reactions at lower liquid flow rates. In contrast, trickle bed reactors consist of continuous liquid flow trickling over a packed catalyst bed, promoting efficient gas-liquid-solid interactions suitable for larger-scale processes with higher liquid throughput. The configuration of dropwise reactors supports precise control of reaction zones, whereas trickle bed reactors provide robust scalability and easier catalyst bed management in industrial applications.

Mass Transfer Efficiency: Dropwise vs Trickle Bed

Dropwise reactors exhibit higher mass transfer efficiency due to enhanced surface area contact between droplets and the gas phase, promoting rapid diffusion and improved reaction rates. Trickle bed reactors rely on liquid trickling over solid catalysts, leading to limited surface renewal and potential mass transfer resistance in the liquid film. Your choice between these reactors depends on process requirements for optimal gas-liquid mass transfer and catalyst utilization.

Catalyst Utilization and Distribution

Dropwise reactors offer improved catalyst utilization by ensuring direct and uniform contact between liquid reactants and catalyst particles, minimizing diffusional limitations. Trickle bed reactors rely on a continuous liquid film flowing over a packed catalyst bed, which can result in uneven catalyst distribution and potential channeling, reducing effective catalyst surface area exposure. Your choice between these reactors should consider how catalyst contact efficiency impacts reaction rates and product yield in your specific process.

Operational Flexibility and Scalability

Dropwise reactors offer high operational flexibility by allowing precise control over droplet size and residence time, which optimizes reaction rates for various feed compositions. Trickle bed reactors scale efficiently for large continuous operations due to their fixed catalyst beds, maintaining consistent gas-liquid-solid contact and pressure drop management. Both reactors cater to different scalability needs, with dropwise systems favoring laboratory and pilot scales and trickle bed units suited for industrial-scale multiphase reactions.

Typical Applications in Industry

Dropwise reactors are predominantly used in fine chemical synthesis and high-precision pharmaceutical manufacturing due to their efficient mass transfer and temperature control. Trickle bed reactors find extensive application in petrochemical refining, wastewater treatment, and hydrotreating processes where gas-liquid-solid interactions are critical for catalyst performance. Both reactor types optimize reaction efficiency but cater to distinct industrial needs based on phase distribution and catalyst contact.

Advantages and Limitations of Each Reactor

Dropwise reactors offer enhanced mass transfer and improved catalyst utilization due to superior liquid distribution, making them ideal for fast reaction kinetics. However, they face limitations in scalability and may experience channeling or maldistribution at higher flow rates. Trickle bed reactors provide robust operation with easier scale-up and better handling of solid catalysts, but suffer from lower mass transfer efficiency and potential catalyst deactivation due to uneven wetting.

Future Trends and Technological Developments

Future trends in dropwise reactors emphasize enhanced mass transfer efficiency through advanced catalyst designs and microchannel integration, boosting reaction rates and selectivity. Trickle bed reactors focus on improved liquid distribution and catalyst longevity using novel packing materials and real-time monitoring technologies to optimize operational stability. Your choice between these reactors will benefit from ongoing digitalization and process intensification approaches, driving sustainability and cost-effectiveness in industrial applications.

dropwise reactor vs trickle bed reactor Infographic

libmatt.com

libmatt.com