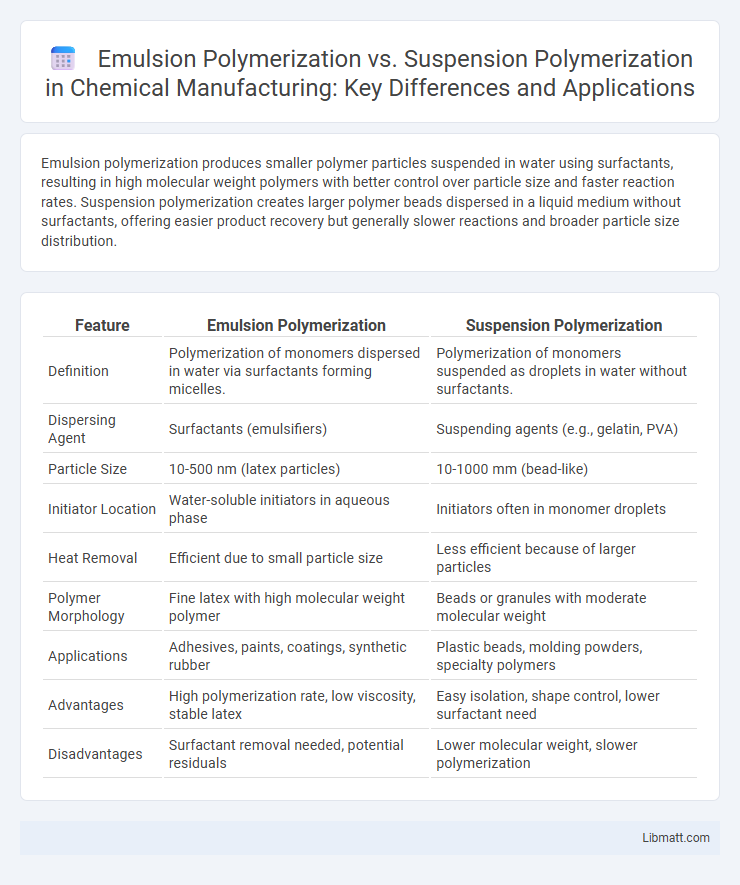

Emulsion polymerization produces smaller polymer particles suspended in water using surfactants, resulting in high molecular weight polymers with better control over particle size and faster reaction rates. Suspension polymerization creates larger polymer beads dispersed in a liquid medium without surfactants, offering easier product recovery but generally slower reactions and broader particle size distribution.

Table of Comparison

| Feature | Emulsion Polymerization | Suspension Polymerization |

|---|---|---|

| Definition | Polymerization of monomers dispersed in water via surfactants forming micelles. | Polymerization of monomers suspended as droplets in water without surfactants. |

| Dispersing Agent | Surfactants (emulsifiers) | Suspending agents (e.g., gelatin, PVA) |

| Particle Size | 10-500 nm (latex particles) | 10-1000 mm (bead-like) |

| Initiator Location | Water-soluble initiators in aqueous phase | Initiators often in monomer droplets |

| Heat Removal | Efficient due to small particle size | Less efficient because of larger particles |

| Polymer Morphology | Fine latex with high molecular weight polymer | Beads or granules with moderate molecular weight |

| Applications | Adhesives, paints, coatings, synthetic rubber | Plastic beads, molding powders, specialty polymers |

| Advantages | High polymerization rate, low viscosity, stable latex | Easy isolation, shape control, lower surfactant need |

| Disadvantages | Surfactant removal needed, potential residuals | Lower molecular weight, slower polymerization |

Introduction to Emulsion and Suspension Polymerization

Emulsion polymerization uses water as the continuous phase with monomer droplets stabilized by surfactants, producing high molecular weight polymers with fine particle sizes suitable for paints and adhesives. Suspension polymerization disperses monomer droplets in a liquid phase without surfactants, forming larger polymer beads ideal for applications like ion-exchange resins and plastic molding. Both methods enable controlled polymer particle size and morphology but differ in mechanisms, stabilizers, and typical product properties.

Fundamental Principles of Emulsion Polymerization

Emulsion polymerization operates by dispersing monomer droplets in water with the help of surfactants, forming micelles where polymerization initiates. This technique offers high control over particle size and results in stable latex particles due to the insulating effect of the surfactant layer. Your choice of emulsion polymerization can enhance polymer properties through efficient heat dissipation and rapid polymerization rates.

Core Concepts of Suspension Polymerization

Suspension polymerization involves dispersing monomer droplets in a continuous phase, usually water, stabilized by mechanical agitation and suspending agents to form polymer beads. This method yields larger, spherical polymer particles with good heat dissipation and ease of handling in industrial processes. The core concept centers on maintaining discrete monomer droplets throughout polymerization, preventing coalescence and enabling uniform particle size distribution.

Key Monomers Used in Both Polymerization Methods

Emulsion polymerization commonly uses monomers such as styrene, butadiene, acrylonitrile, and vinyl acetate, which are ideal due to their hydrophobic nature and ability to form stable latex particles. Suspension polymerization typically employs monomers like methyl methacrylate, vinyl chloride, and acrylonitrile, favored for their higher polymerization rates in dispersed droplets. Understanding the key monomers used in these methods can help you select the appropriate polymerization technique for specific polymer properties and applications.

Initiation Mechanisms: Emulsion vs Suspension

Emulsion polymerization initiates through free radical generation in the aqueous phase, typically using water-soluble initiators that produce radicals which then enter micelles containing monomer droplets, enabling rapid polymerization within these micelles. Suspension polymerization initiation occurs mainly in the monomer droplets themselves, where initiators--often oil-soluble or dispersed in the monomer phase--generate radicals locally, causing polymer chains to grow within each droplet. The distinct initiation mechanisms result in different particle size distributions and polymer properties, with emulsion polymerization yielding smaller, more uniform latex particles compared to the larger bead-like particles from suspension polymerization.

Particle Size Distribution and Morphology

Emulsion polymerization typically produces polymer particles with a narrow particle size distribution, generally in the range of 10 to 500 nm, resulting in uniform and spherical morphology due to micelle nucleation. Suspension polymerization yields larger particles, usually between 10 and 1000 um, with a broader size distribution influenced by mechanical agitation and stabilizer concentration, often leading to irregular or spherical shapes. The controlled nucleation and surfactant presence in emulsion polymerization enable better control over particle morphology compared to suspension polymerization, where particle growth occurs via monomer droplet polymerization.

Process Conditions and Equipment Considerations

Emulsion polymerization operates under high agitation using surfactants to create micelles, typically requiring specialized high-shear mixers and temperature-controlled reactors to maintain stable latex particles. Suspension polymerization involves larger monomer droplets stabilized by mechanical stirring and protective colloids, demanding robust stirrers and reactors designed to handle slurry systems with lower surfactant concentrations. Process conditions for emulsion polymerization favor rapid polymerization rates at moderate temperatures, while suspension polymerization is suited for slower polymerization with easier particle recovery in batch or continuous stirred tank reactors.

Advantages and Disadvantages of Each Method

Emulsion polymerization offers advantages such as high molecular weight polymers, better heat dissipation, and producing stable latex with small particle size, but faces challenges like the need for surfactants and potential removal difficulties. Suspension polymerization allows easy heat transfer, direct bead formation, and avoids surfactants, making purification simpler; however, it often results in lower molecular weights and broader particle size distribution. Both methods differ in polymerization rate, molecular weight control, and particle morphology, influencing their suitability for various industrial applications.

Industrial Applications and Product Examples

Emulsion polymerization is widely used in producing latex paints, adhesives, and synthetic rubbers due to its ability to create fine polymer particles with high molecular weight, offering excellent film-forming properties. Suspension polymerization finds industrial applications in manufacturing plastics such as polystyrene beads and PVC granules, where larger polymer beads are preferred for ease of handling and processing. Your choice between these methods depends on the desired product properties and end-use applications, especially in sectors like coatings, packaging, and automotive parts.

Conclusion: Choosing the Right Polymerization Technique

Emulsion polymerization offers superior control over particle size and high molecular weight polymers, making it ideal for producing latexes and adhesives with fine dispersion. Suspension polymerization provides larger, more uniform beads suitable for applications requiring easily separable polymer particles, such as ion-exchange resins and PVC production. Selecting the right polymerization technique depends on the desired polymer properties, particle morphology, and scalability requirements of the final product.

Emulsion polymerization vs suspension polymerization Infographic

libmatt.com

libmatt.com