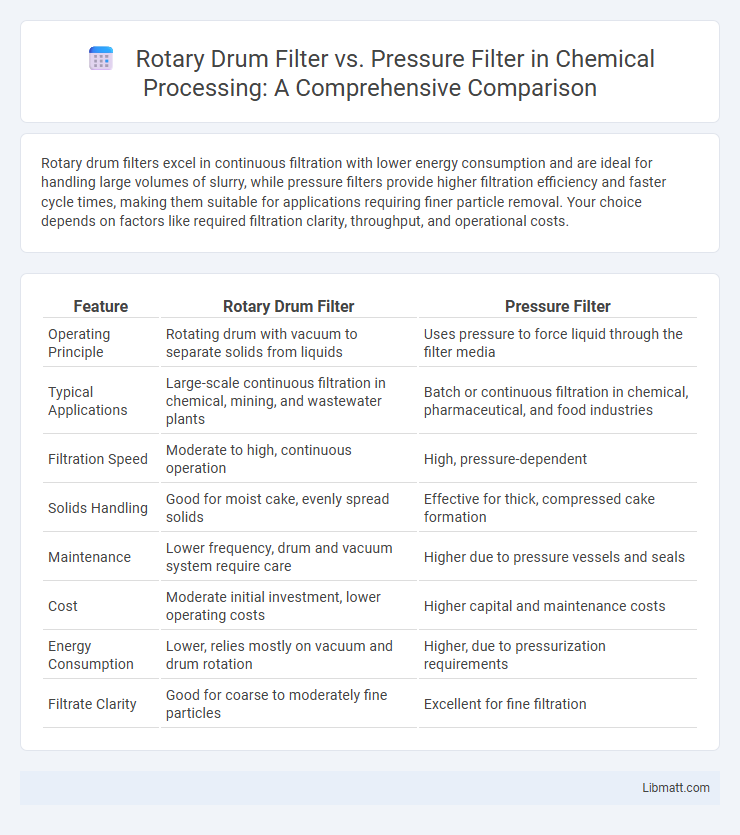

Rotary drum filters excel in continuous filtration with lower energy consumption and are ideal for handling large volumes of slurry, while pressure filters provide higher filtration efficiency and faster cycle times, making them suitable for applications requiring finer particle removal. Your choice depends on factors like required filtration clarity, throughput, and operational costs.

Table of Comparison

| Feature | Rotary Drum Filter | Pressure Filter |

|---|---|---|

| Operating Principle | Rotating drum with vacuum to separate solids from liquids | Uses pressure to force liquid through the filter media |

| Typical Applications | Large-scale continuous filtration in chemical, mining, and wastewater plants | Batch or continuous filtration in chemical, pharmaceutical, and food industries |

| Filtration Speed | Moderate to high, continuous operation | High, pressure-dependent |

| Solids Handling | Good for moist cake, evenly spread solids | Effective for thick, compressed cake formation |

| Maintenance | Lower frequency, drum and vacuum system require care | Higher due to pressure vessels and seals |

| Cost | Moderate initial investment, lower operating costs | Higher capital and maintenance costs |

| Energy Consumption | Lower, relies mostly on vacuum and drum rotation | Higher, due to pressurization requirements |

| Filtrate Clarity | Good for coarse to moderately fine particles | Excellent for fine filtration |

Introduction to Rotary Drum Filters and Pressure Filters

Rotary drum filters use a rotating cylindrical drum covered with a filter medium to separate solids from liquids through vacuum suction, ideal for continuous filtration in industries like mining and wastewater treatment. Pressure filters operate by forcing slurry through a filter medium under high pressure, achieving faster filtration rates suitable for chemical processing and pharmaceuticals. Both types optimize solid-liquid separation but differ in operational mechanisms, capacity, and application specifics.

Working Principle of Rotary Drum Filters

Rotary drum filters operate on the principle of continuous filtration, where a rotating drum partially submerged in slurry allows the liquid to pass through a filter cloth while solids form a cake on the surface. As the drum rotates, vacuum suction draws the liquid through the filter medium, leaving the solid particles on the drum surface for subsequent washing and drying stages. This mechanism enables efficient separation in industries such as mining, chemical processing, and wastewater treatment.

Working Principle of Pressure Filters

Pressure filters operate by forcing liquid through a filter medium using positive pressure, effectively separating solids from liquids in various industrial processes. The filtration occurs as the slurry is pumped into a sealed vessel, where pressure drives the filtrate through the media, leaving a solid cake behind. Understanding this working principle helps you choose the right filtration technology based on capacity, filtration rate, and cake dryness requirements.

Key Differences in Filtration Mechanisms

Rotary drum filters operate on a continuous vacuum filtration principle, where the drum rotates through the slurry, creating a filter cake on the drum surface that is then scraped off. Pressure filters use applied pressure to force liquid through a filter medium, capturing solids inside a sealed chamber for batch processing. The rotary drum filter excels in handling large volumes with moderate filtration precision, while pressure filters deliver higher solids dryness and finer filtration in controlled cycles.

Performance Comparison: Filtration Rate and Efficiency

Rotary drum filters typically offer higher filtration rates due to their continuous operation and large filter area, making them ideal for high-volume slurry processing. Pressure filters often achieve superior filtration efficiency by applying controlled pressure, resulting in drier filter cakes and better contaminant removal. Your choice between these filters depends on whether filtration rate or cake dryness and purity align better with your process requirements.

Applications and Industry Uses

Rotary drum filters are widely used in wastewater treatment, mining, and chemical industries for continuous solid-liquid separation, excelling in handling large volumes with moderate filtration needs. Pressure filters are favored in pharmaceuticals, food processing, and fine chemicals for their ability to achieve higher filtration precision and handle viscous or difficult slurries under controlled pressure. Your choice between these filters depends on the specific application requirements such as filtration speed, particle size, and slurry characteristics.

Maintenance and Operational Considerations

Rotary drum filters require routine cleaning and regular inspection of filter media to prevent clogging and maintain filtration efficiency, while pressure filters demand frequent backwashing and monitoring of pressure differentials to avoid media compaction. Operational considerations include rotary drum filters' suitability for continuous, large-scale filtration with lower energy consumption, whereas pressure filters operate under higher pressure, offering faster filtration cycles but necessitating more robust maintenance protocols. Both technologies benefit from scheduled maintenance to minimize downtime and extend equipment lifespan in industrial and wastewater treatment applications.

Cost Analysis: Initial Investment and Operating Costs

Rotary drum filters typically have a higher initial investment due to their complex mechanical components and large footprint, but they offer lower operating costs through continuous operation and reduced labor requirements. Pressure filters generally require less upfront capital, ideal for smaller-scale operations, yet they incur higher operating expenses because of frequent maintenance and energy-intensive pressurization. Evaluating total cost of ownership depends on production scale, with rotary drum filters favored for high-volume, continuous processes and pressure filters suited for batch or lower-capacity applications.

Environmental Impact and Sludge Handling

Rotary drum filters generate less wastewater due to continuous filtration, reducing environmental impact, while pressure filters often require more backwash water, increasing effluent volume. Sludge from rotary drum filters is typically drier and easier to handle, lowering disposal costs and environmental burden. Your choice affects sludge management efficiency and overall environmental footprint in industrial filtration processes.

Choosing the Right Filter: Factors to Consider

When choosing between a rotary drum filter and a pressure filter, key factors include processing capacity, cake dryness, and maintenance requirements. Rotary drum filters excel in continuous operation and high throughput for slurry with fine solids, while pressure filters offer higher cake dryness and are suitable for batch processes with varying feed compositions. Material compatibility, energy consumption, and operational costs should also guide the decision to optimize filtration efficiency and lifecycle performance.

Rotary drum filter vs pressure filter Infographic

libmatt.com

libmatt.com