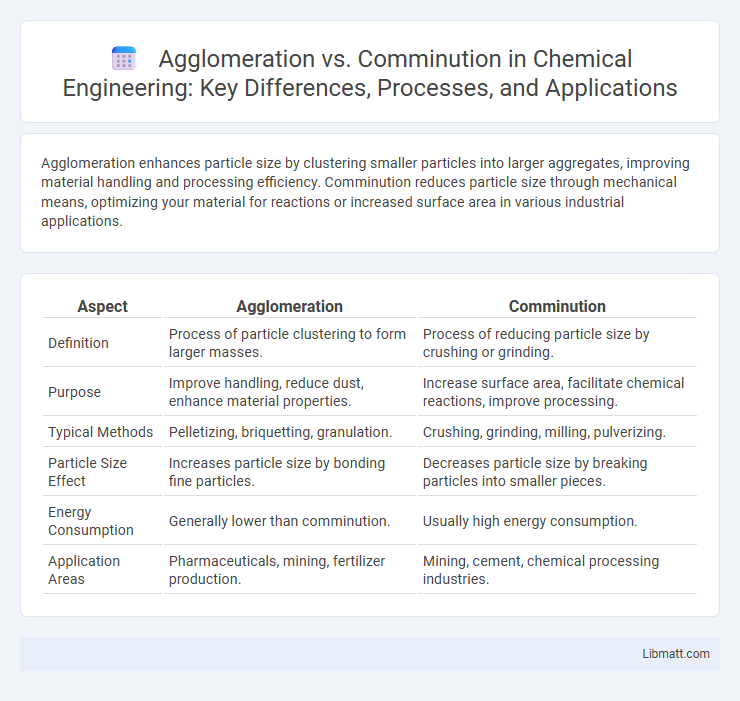

Agglomeration enhances particle size by clustering smaller particles into larger aggregates, improving material handling and processing efficiency. Comminution reduces particle size through mechanical means, optimizing your material for reactions or increased surface area in various industrial applications.

Table of Comparison

| Aspect | Agglomeration | Comminution |

|---|---|---|

| Definition | Process of particle clustering to form larger masses. | Process of reducing particle size by crushing or grinding. |

| Purpose | Improve handling, reduce dust, enhance material properties. | Increase surface area, facilitate chemical reactions, improve processing. |

| Typical Methods | Pelletizing, briquetting, granulation. | Crushing, grinding, milling, pulverizing. |

| Particle Size Effect | Increases particle size by bonding fine particles. | Decreases particle size by breaking particles into smaller pieces. |

| Energy Consumption | Generally lower than comminution. | Usually high energy consumption. |

| Application Areas | Pharmaceuticals, mining, fertilizer production. | Mining, cement, chemical processing industries. |

Introduction to Agglomeration and Comminution

Agglomeration and comminution are critical processes in mineral processing and material handling, each serving distinct purposes in particle size modification. Agglomeration involves the aggregation of fine particles into larger, more manageable masses, enhancing material flow and processing efficiency. Comminution refers to the mechanical size reduction of ores or materials through crushing and grinding, aiming to liberate valuable minerals for subsequent extraction.

Fundamental Concepts: Agglomeration Defined

Agglomeration is the process of clustering fine particles into larger, more manageable masses, improving material handling and processing efficiency. This technique contrasts with comminution, which involves breaking down materials into finer particles to increase surface area. Understanding agglomeration enhances your ability to optimize industrial workflows by balancing particle size for better performance.

Understanding Comminution: Processes and Principles

Comminution involves the reduction of solid materials into smaller particles through crushing, grinding, and milling, essential for liberating valuable minerals in mining and mineral processing. You can optimize material handling and improve downstream efficiency by understanding key principles like size reduction mechanisms, energy consumption, and equipment selection. Agglomeration often follows comminution to enhance material flow, but mastering comminution processes is critical for maximizing recovery rates and operational productivity.

Key Differences Between Agglomeration and Comminution

Agglomeration involves the process of gathering small particles into larger, more cohesive masses to improve material handling and processing efficiency, whereas comminution refers to the size reduction of solid materials through crushing and grinding to produce finer particles. Agglomeration enhances properties like flowability and permeability in powders, while comminution primarily increases surface area and alters particle size distribution for subsequent chemical or physical processing. The fundamental difference lies in agglomeration building particle clusters versus comminution breaking particles down into smaller fragments.

Applications of Agglomeration in Industry

Agglomeration processes are widely used in industries such as mining, pharmaceuticals, and food processing to enhance particle size and improve handling and processing efficiency. In mining, agglomeration facilitates the formation of larger, porous pellets from fine powders, optimizing heap leaching and smelting operations. Pharmaceutical manufacturing applies agglomeration for granule formation, improving drug stability and dissolution rates in tablet production.

Industrial Uses of Comminution Techniques

Comminution techniques are essential in industries such as mining, cement production, and pharmaceuticals for reducing particle size to enhance processing efficiency and product quality. These methods, including crushing, grinding, and milling, enable the liberation of valuable minerals and facilitate downstream extraction or chemical reactions. Your industrial operations benefit from optimized comminution processes by improving material handling, energy consumption, and overall production throughput.

Advantages and Disadvantages of Agglomeration

Agglomeration improves particle size distribution, enhancing material handling and processing efficiency while reducing dust generation and wear on equipment. However, it requires additional energy input and equipment, which can increase operational costs and complexity. Your choice between agglomeration and comminution should balance improved product quality against these economic and process considerations.

Benefits and Limitations of Comminution

Comminution offers significant benefits such as particle size reduction, improved mineral liberation, and enhanced downstream processing efficiency in mining and mineral processing industries. However, it has limitations including high energy consumption, equipment wear, and potential generation of excessive fines that can complicate separation processes. Optimizing Your comminution circuit is crucial to balance energy usage and maintain product quality for efficient mineral extraction.

Factors Influencing Process Selection

Factors influencing the selection between agglomeration and comminution include material properties such as hardness, moisture content, and particle size distribution. Equipment availability, energy consumption, and desired final product specifications also play critical roles in determining the most efficient process. Economic considerations, including operational costs and throughput requirements, further guide the decision-making process in mineral processing and powder handling industries.

Future Trends in Particle Size Management

Future trends in particle size management emphasize integrating AI-driven sensors and real-time data analytics to enhance precision in agglomeration and comminution processes. Emerging technologies such as advanced microfluidic systems and novel grinding media optimize energy efficiency and particle uniformity. Sustainable practices prioritize reducing waste and carbon footprint while improving scalability and product quality in industrial applications.

Agglomeration vs comminution Infographic

libmatt.com

libmatt.com