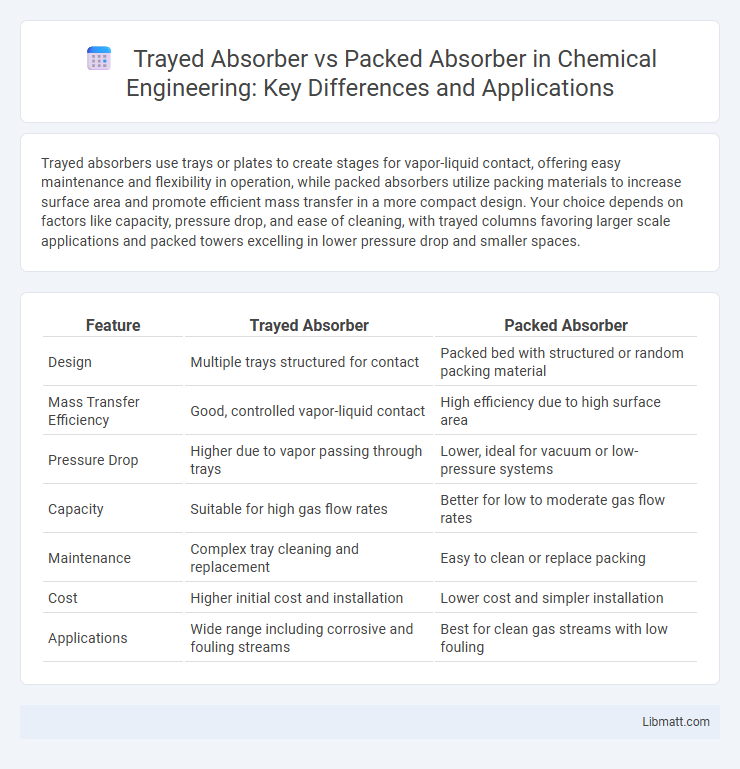

Trayed absorbers use trays or plates to create stages for vapor-liquid contact, offering easy maintenance and flexibility in operation, while packed absorbers utilize packing materials to increase surface area and promote efficient mass transfer in a more compact design. Your choice depends on factors like capacity, pressure drop, and ease of cleaning, with trayed columns favoring larger scale applications and packed towers excelling in lower pressure drop and smaller spaces.

Table of Comparison

| Feature | Trayed Absorber | Packed Absorber |

|---|---|---|

| Design | Multiple trays structured for contact | Packed bed with structured or random packing material |

| Mass Transfer Efficiency | Good, controlled vapor-liquid contact | High efficiency due to high surface area |

| Pressure Drop | Higher due to vapor passing through trays | Lower, ideal for vacuum or low-pressure systems |

| Capacity | Suitable for high gas flow rates | Better for low to moderate gas flow rates |

| Maintenance | Complex tray cleaning and replacement | Easy to clean or replace packing |

| Cost | Higher initial cost and installation | Lower cost and simpler installation |

| Applications | Wide range including corrosive and fouling streams | Best for clean gas streams with low fouling |

Introduction to Trayed and Packed Absorbers

Trayed absorbers utilize a series of perforated trays to facilitate vapor-liquid contact, enhancing mass transfer efficiency in gas absorption processes. Packed absorbers, conversely, employ structured or random packing materials that provide a large surface area for intimate gas-liquid interaction, optimizing absorption rates. Both systems serve critical roles in chemical industries, with selection dependent on factors such as pressure drop, capacity, and ease of maintenance.

Design Principles of Trayed Absorbers

Trayed absorbers utilize a series of trays or plates arranged vertically to promote contact between vapor and liquid phases, facilitating mass transfer through bubble flow and weeping mechanisms. These trays are designed to optimize vapor-liquid contact time and minimize pressure drop by controlling tray spacing, hole size, and weir height. Your selection of trayed absorbers hinges on factors like capacity, fouling tendencies, and ease of maintenance, which influence the design principles for efficient absorption.

Design Principles of Packed Absorbers

Packed absorbers utilize a column filled with structured or random packing materials to maximize the surface area for gas-liquid contact, enhancing mass transfer efficiency. You must consider parameters such as packing type, height, diameter, and liquid distribution to optimize performance based on gas flow rates and absorption requirements. The design principles focus on minimizing pressure drop and ensuring uniform fluid distribution to achieve efficient absorption compared to trayed absorbers.

Mass Transfer Mechanisms in Absorbers

Trayed absorbers rely on stages where gas and liquid phases contact on trays, enabling mass transfer through discrete, well-defined interfaces, facilitating efficient gas-liquid interaction via bubble formation and froth dynamics. Packed absorbers use structured or random packing materials, creating continuous liquid films over surfaces, enhancing mass transfer by increasing surface area and promoting turbulent mixing within the packing. Your choice between trayed and packed absorbers impacts the mass transfer efficiency based on the gas-liquid contact mode and operational conditions.

Efficiency Comparison: Trayed vs Packed Absorbers

Trayed absorbers typically offer higher mass transfer efficiency due to their staged contact design, enabling better control over vapor-liquid equilibrium compared to packed absorbers. Packed absorbers provide a larger surface area and lower pressure drop, making them efficient for applications with low to moderate flow rates but often less efficient in separation performance. Your choice between trayed and packed absorbers should consider the specific efficiency requirements and operational conditions of the absorption process.

Pressure Drop Analysis in Both Absorber Types

Trayed absorbers typically exhibit higher pressure drops due to liquid holdup and vapor flow resistance across trays, making them less efficient in low-pressure systems. Packed absorbers have lower pressure drops as their random or structured packing allows more uniform vapor-liquid contact and reduced flow obstruction. Optimizing pressure drop involves balancing packing material, size, and tray design to minimize energy consumption and maintain effective mass transfer.

Scalability and Industrial Applications

Packed absorbers offer superior scalability for large-scale industrial applications due to their flexible design and ability to handle varying flow rates efficiently. Trayed absorbers provide more precise liquid-gas contact with easier maintenance, making them ideal for smaller-scale or specialized processes where operational control is critical. Your choice depends on the plant size, with packed absorbers favored for bulk gas treatment and trayed absorbers preferred in industries requiring precise mass transfer control.

Maintenance and Operational Considerations

Trayed absorbers feature trays that can require frequent inspection and cleaning to prevent fouling and maintain efficiency, which may lead to higher operational downtime. Packed absorbers demand less routine maintenance but involve careful handling of packing materials to avoid channeling and pressure drop issues. Your choice should balance ease of maintenance with operational stability based on process conditions and desired longevity.

Cost Implications and Economic Analysis

Trayed absorbers generally incur higher capital costs due to complex tray design and installation, whereas packed absorbers offer lower upfront expenses with simpler media packing. Operating expenses for trayed absorbers may be higher caused by increased pressure drop and maintenance needs, while packed absorbers provide energy-efficient operation and reduced solvent loss. Economic analysis reveals that packed absorbers are often more cost-effective in large-scale, low-pressure applications, whereas trayed absorbers suit scenarios requiring precise stage control despite higher investment.

Selection Criteria: Choosing Trayed or Packed Absorbers

Selection criteria for choosing trayed or packed absorbers depend on factors such as gas-liquid contact efficiency, operating pressure, and capacity requirements. Trayed absorbers are preferred for high capacity operations and gases with fouling tendencies due to their robustness and ease of maintenance. Packed absorbers offer better efficiency at lower pressure drops and are ideal for corrosive fluids or close temperature approaches where mass transfer efficiency is critical.

Trayed absorber vs packed absorber Infographic

libmatt.com

libmatt.com