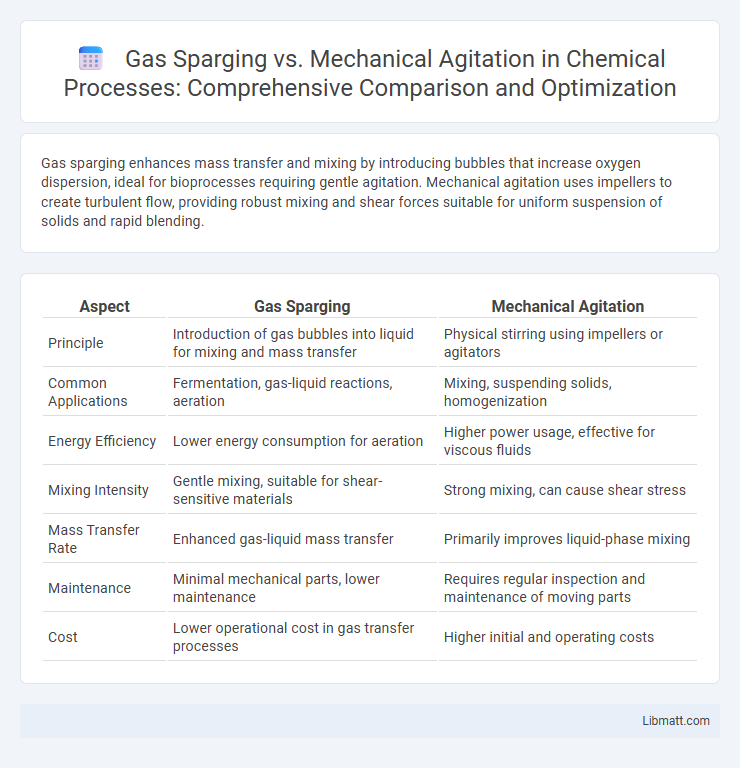

Gas sparging enhances mass transfer and mixing by introducing bubbles that increase oxygen dispersion, ideal for bioprocesses requiring gentle agitation. Mechanical agitation uses impellers to create turbulent flow, providing robust mixing and shear forces suitable for uniform suspension of solids and rapid blending.

Table of Comparison

| Aspect | Gas Sparging | Mechanical Agitation |

|---|---|---|

| Principle | Introduction of gas bubbles into liquid for mixing and mass transfer | Physical stirring using impellers or agitators |

| Common Applications | Fermentation, gas-liquid reactions, aeration | Mixing, suspending solids, homogenization |

| Energy Efficiency | Lower energy consumption for aeration | Higher power usage, effective for viscous fluids |

| Mixing Intensity | Gentle mixing, suitable for shear-sensitive materials | Strong mixing, can cause shear stress |

| Mass Transfer Rate | Enhanced gas-liquid mass transfer | Primarily improves liquid-phase mixing |

| Maintenance | Minimal mechanical parts, lower maintenance | Requires regular inspection and maintenance of moving parts |

| Cost | Lower operational cost in gas transfer processes | Higher initial and operating costs |

Introduction to Gas Sparging and Mechanical Agitation

Gas sparging involves injecting gas bubbles directly into liquids to enhance mixing and mass transfer, commonly used in bioreactors and wastewater treatment. Mechanical agitation employs impellers or paddles to create fluid motion, promoting uniform distribution of nutrients, gases, and temperature in various industrial processes. Both methods optimize mixing efficiency but differ in energy consumption, shear stress, and application suitability depending on the system's requirements.

Core Principles of Gas Sparging

Gas sparging relies on injecting gas bubbles directly into a liquid to enhance mass transfer and mixing efficiency, promoting improved oxygen transfer rates essential for biochemical processes. This method creates fine gas dispersion that increases the interfacial surface area between gas and liquid, optimizing nutrient and gas exchange in bioreactors. Your choice of gas sparging allows precise control of gas flow rates and bubble size, resulting in more efficient aeration and reduced energy consumption compared to mechanical agitation.

Fundamentals of Mechanical Agitation

Mechanical agitation relies on rotating impellers or paddles to create fluid motion, ensuring uniform mixing, heat transfer, and suspension of solids. This method uses direct energy input to break up particle clusters and enhance mass transfer rates within the liquid medium. You can optimize processes by adjusting agitation speed, impeller type, and placement, tailoring the flow patterns for efficient mixing and reaction control.

Efficiency Comparison: Gas Sparging vs Mechanical Agitation

Gas sparging enhances mass transfer efficiency by introducing fine gas bubbles directly into the liquid, increasing surface area contact and promoting rapid oxygenation or stripping of volatile compounds. Mechanical agitation relies on physical mixing, which efficiently homogenizes the solution but often consumes more energy and may create shear sensitive issues in delicate systems. Your choice depends on process requirements, with gas sparging offering superior efficiency for gas-liquid interactions, while mechanical agitation provides broader mixing capabilities.

Impact on Mass Transfer Rates

Gas sparging enhances mass transfer rates by increasing gas-liquid interfacial area and promoting bubble dispersion, resulting in improved oxygen or reactant solubility in bioreactors and fermenters. Mechanical agitation primarily improves mass transfer through turbulence and mixing, reducing boundary layer thickness and enhancing diffusion rates within the liquid medium. Combining both techniques often synergistically maximizes mass transfer efficiency, especially in high-viscosity or viscous fermentation processes.

Equipment Design and Operational Considerations

Gas sparging equipment features spargers and diffusers designed to introduce gas bubbles efficiently into liquid, optimizing mass transfer rates while minimizing shear stress. Mechanical agitation relies on impellers and shafts engineered to produce controlled turbulence and mixing intensity, affecting energy consumption and scale-up complexity. Your choice depends on process requirements, as gas sparging offers gentler mixing suitable for biological cultures, whereas mechanical agitation provides vigorous mixing ideal for homogeneous chemical reactions.

Energy Consumption and Cost Analysis

Gas sparging typically consumes less energy compared to mechanical agitation because it relies on bubble-induced mixing rather than motor-driven impellers. Your operational cost may decrease with gas sparging due to lower power requirements and reduced maintenance expenses associated with moving parts. However, initial equipment costs and specific process demands should be evaluated to determine the most cost-effective solution.

Applicability to Different Industrial Processes

Gas sparging is highly effective in fermentation, wastewater treatment, and fine chemical production where oxygen transfer and gentle mixing are crucial. Mechanical agitation suits high-viscosity fluids and processes requiring intense mixing, such as slurry reactors and polymerization. Choosing between gas sparging and mechanical agitation depends on factors like fluid properties, oxygen requirements, and desired mixing intensity.

Advantages and Limitations of Each Method

Gas sparging enhances mass transfer and mixing efficiency by introducing fine gas bubbles directly into the liquid, resulting in improved oxygen transfer rates and reduced energy consumption; however, it may cause foaming and gas holdup challenges that limit scalability. Mechanical agitation provides consistent and controllable mixing through impellers or stirrers, offering superior homogenization and shear control but often requires higher energy input and maintenance costs. Both methods' effectiveness depends on specific process conditions such as reactor size, fluid properties, and desired mixing intensity.

Choosing the Right Mixing Technique for Your Application

Gas sparging enhances mass transfer and gas-liquid interactions, making it ideal for applications like fermentation and aerobic bioprocesses. Mechanical agitation provides vigorous mixing and homogeneity, suitable for high-viscosity fluids or solids suspension. Evaluate your process requirements, such as oxygen transfer rate, shear sensitivity, and energy efficiency, to choose the right mixing technique for your application.

Gas sparging vs mechanical agitation Infographic

libmatt.com

libmatt.com