Vapor phase reactions occur with reactants in the gas state, offering faster diffusion and better heat transfer, which often results in higher reaction rates compared to liquid phase reactions. Your choice between the two depends on factors like reaction kinetics, temperature control, and product separation efficiency.

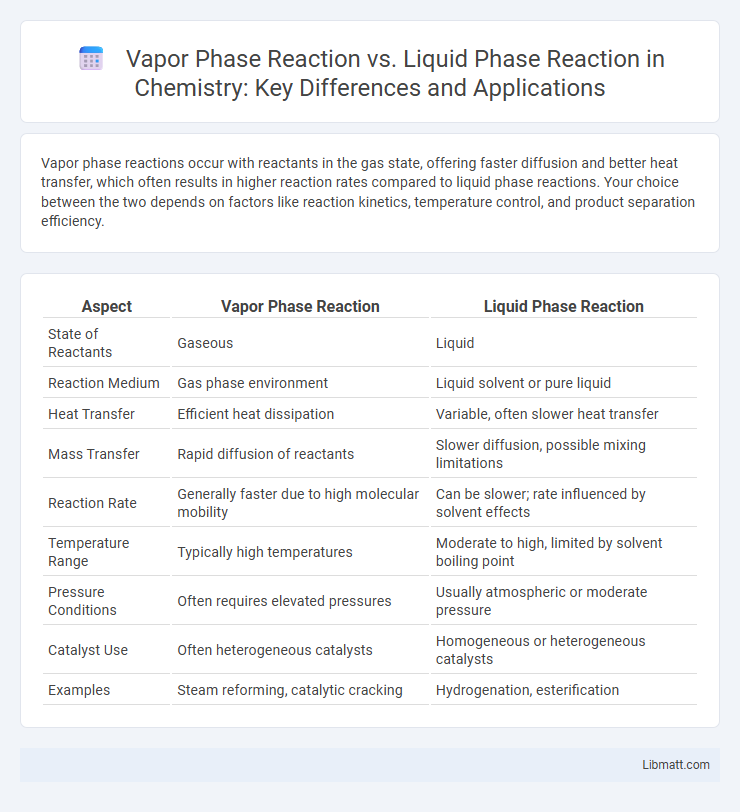

Table of Comparison

| Aspect | Vapor Phase Reaction | Liquid Phase Reaction |

|---|---|---|

| State of Reactants | Gaseous | Liquid |

| Reaction Medium | Gas phase environment | Liquid solvent or pure liquid |

| Heat Transfer | Efficient heat dissipation | Variable, often slower heat transfer |

| Mass Transfer | Rapid diffusion of reactants | Slower diffusion, possible mixing limitations |

| Reaction Rate | Generally faster due to high molecular mobility | Can be slower; rate influenced by solvent effects |

| Temperature Range | Typically high temperatures | Moderate to high, limited by solvent boiling point |

| Pressure Conditions | Often requires elevated pressures | Usually atmospheric or moderate pressure |

| Catalyst Use | Often heterogeneous catalysts | Homogeneous or heterogeneous catalysts |

| Examples | Steam reforming, catalytic cracking | Hydrogenation, esterification |

Introduction to Vapor Phase and Liquid Phase Reactions

Vapor phase reactions occur in the gas state, where reactants are vaporized and interact at elevated temperatures, often enhancing reaction rates and selectivity in processes like catalytic reforming. Liquid phase reactions involve reactants dissolved or suspended in a liquid medium, providing controlled environments for processes such as hydrolysis and hydrogenation, which benefit from solvent stabilization. Your choice between vapor phase and liquid phase reactions depends on factors like reaction kinetics, temperature control, and desired product specificity.

Fundamental Concepts of Phase-Based Reactions

Vapor phase reactions occur when reactants are in the gaseous state, enabling rapid molecular collisions and enhanced diffusion rates due to higher kinetic energy, which often leads to faster reaction kinetics compared to liquid phase reactions. Liquid phase reactions involve reactants dissolved or dispersed in a liquid medium, allowing for better solvation and stabilization of intermediates but typically experiencing slower mass transfer and reaction rates. The fundamental distinction lies in the phase-dependent molecular interactions and transport phenomena, influencing catalyst selection, reaction mechanisms, and process optimization in industrial chemistry.

Key Differences Between Vapor and Liquid Phase Reactions

Vapor phase reactions typically occur at higher temperatures and lower densities compared to liquid phase reactions, influencing reaction rates and mechanisms. The increased molecular mobility and diffusivity in the vapor phase often lead to faster reaction kinetics and easier control of product distribution. In contrast, liquid phase reactions benefit from better solvent interactions and heat transfer, enabling selective reactions and improved catalyst stability.

Mechanisms of Vapor Phase Reactions

Vapor phase reactions typically involve gas-phase molecules undergoing collisions that lead to bond-breaking and formation through radical or ionic intermediates, often facilitated by high temperatures and catalysts on solid surfaces. Reaction mechanisms in the vapor phase are dominated by adsorption-desorption steps, surface diffusion, and elementary chemical reactions, which differ fundamentally from the solvation and diffusion-controlled pathways seen in liquid phase reactions. The absence of solvent effects in vapor phase reactions results in distinct kinetic behaviors and activation energies, making catalyst surface properties critical for controlling reaction selectivity and rates.

Mechanisms of Liquid Phase Reactions

Liquid phase reactions typically proceed through mechanisms involving molecular collisions mediated by solvent molecules, which stabilize reaction intermediates and transition states, enhancing reaction rates and selectivity. Solvent polarity and hydrogen bonding significantly influence reaction pathways by altering the energy landscape and facilitating proton transfers or nucleophilic attacks. Your understanding of these mechanisms allows for more efficient catalyst design and optimization in processes like hydrogenation, esterification, and oxidation.

Factors Influencing Reaction Rates in Both Phases

Reaction rates in vapor phase reactions are primarily influenced by temperature, pressure, and reactant concentration, as higher temperatures increase molecular collisions and activation energy in the gas phase. In liquid phase reactions, solvent effects, viscosity, and diffusion rates play crucial roles in determining reaction speed, with the solvent environment affecting reactant solubility and molecular interactions. Your choice between vapor and liquid phase depends on how these factors impact catalytic activity and overall process efficiency.

Advantages of Vapor Phase Reactions

Vapor phase reactions offer enhanced mass transfer rates and uniform temperature control, leading to higher reaction efficiencies compared to liquid phase reactions. These reactions typically operate at higher temperatures and provide easier separation of products due to the gaseous state of reactants and products. Furthermore, vapor phase processes reduce issues related to catalyst deactivation caused by liquid phase impurities or fouling.

Advantages of Liquid Phase Reactions

Liquid phase reactions offer enhanced heat transfer efficiency and better temperature control, minimizing hot spots that can lead to undesired byproducts. The increased density and solubility of reactants in the liquid phase improve reaction rates and selectivity, leading to higher yields. Catalyst recovery and recycling are often easier in liquid phase reactions due to phase separation techniques, contributing to cost-effective and sustainable processes.

Industrial Applications: Vapor vs Liquid Phase

Vapor phase reactions dominate industries such as petrochemical refining and gas-phase catalytic processes due to their enhanced mass transfer and superior heat management, resulting in higher reaction rates and selectivity. Liquid phase reactions are preferred in pharmaceutical synthesis and polymer production where precise control over reaction conditions and ease of catalyst recovery are critical. Your choice between vapor and liquid phase depends on factors like reaction kinetics, heat transfer, and product separation requirements specific to your industrial application.

Summary and Comparative Analysis

Vapor phase reactions typically offer faster reaction rates and enhanced heat transfer compared to liquid phase reactions, making them ideal for processes like catalytic cracking and steam reforming. Liquid phase reactions provide better control over reaction conditions and selectivity due to higher solvent interaction and mass transfer limitations. Understanding the differences helps you optimize your chemical processes by choosing the appropriate phase reaction for desired efficiency and product yield.

vapor phase reaction vs liquid phase reaction Infographic

libmatt.com

libmatt.com