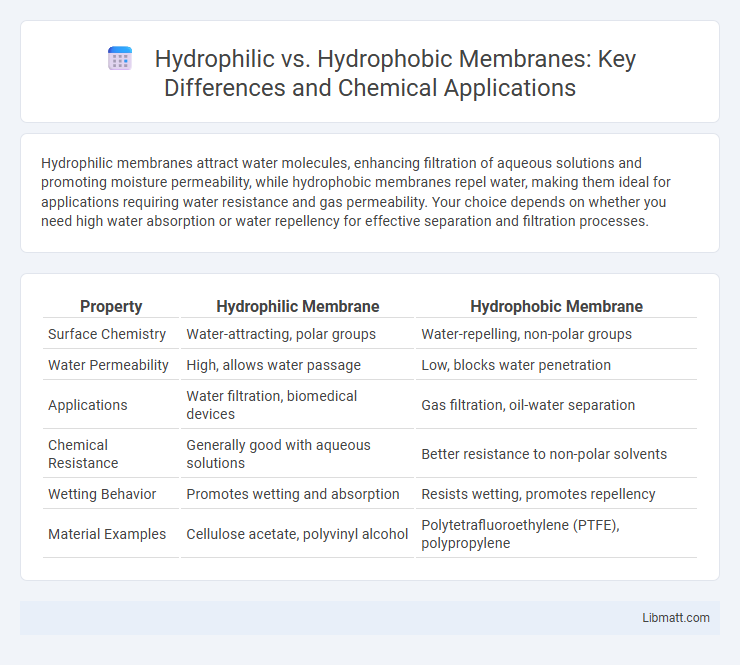

Hydrophilic membranes attract water molecules, enhancing filtration of aqueous solutions and promoting moisture permeability, while hydrophobic membranes repel water, making them ideal for applications requiring water resistance and gas permeability. Your choice depends on whether you need high water absorption or water repellency for effective separation and filtration processes.

Table of Comparison

| Property | Hydrophilic Membrane | Hydrophobic Membrane |

|---|---|---|

| Surface Chemistry | Water-attracting, polar groups | Water-repelling, non-polar groups |

| Water Permeability | High, allows water passage | Low, blocks water penetration |

| Applications | Water filtration, biomedical devices | Gas filtration, oil-water separation |

| Chemical Resistance | Generally good with aqueous solutions | Better resistance to non-polar solvents |

| Wetting Behavior | Promotes wetting and absorption | Resists wetting, promotes repellency |

| Material Examples | Cellulose acetate, polyvinyl alcohol | Polytetrafluoroethylene (PTFE), polypropylene |

Introduction to Membrane Technology

Hydrophilic membranes attract water molecules, facilitating filtration processes in applications such as water purification and biomedical devices, while hydrophobic membranes repel water and are primarily used for gas separation and moisture control. Membrane technology leverages these distinct properties to enhance selective permeability, improve filtration efficiency, and customize separation processes based on hydrophobicity or hydrophilicity. Understanding the surface chemistry and interaction with target molecules is crucial for optimizing membrane performance across industrial, environmental, and healthcare sectors.

Defining Hydrophilic and Hydrophobic Membranes

Hydrophilic membranes attract and absorb water molecules due to their polar surface chemistry, making them ideal for applications requiring water permeation and filtration. Hydrophobic membranes repel water because of their non-polar, water-resistant surface, which is essential for separating gases or non-aqueous liquids. The intrinsic surface energy and chemical composition differentiate hydrophilic membranes, such as cellulose acetate, from hydrophobic membranes like polytetrafluoroethylene (PTFE).

Key Differences Between Hydrophilic and Hydrophobic Membranes

Hydrophilic membranes exhibit strong affinity for water, enhancing water permeability and fouling resistance in filtration processes, while hydrophobic membranes repel water, improving gas separation and oil-water separation applications. The surface energy of hydrophilic membranes promotes wetting and solute adsorption, whereas hydrophobic membranes maintain high selectivity due to their non-polar surface characteristics. Material composition such as polyvinylidene fluoride (PVDF) for hydrophobic membranes and cellulose acetate for hydrophilic membranes directly influences their performance in microfiltration and ultrafiltration systems.

Material Composition and Surface Properties

Hydrophilic membranes are typically composed of polymers like cellulose acetate or polyvinyl alcohol, exhibiting polar functional groups that attract water molecules and enhance wettability. Hydrophobic membranes are made from materials such as polytetrafluoroethylene (PTFE) or polypropylene, characterized by nonpolar surfaces that repel water and resist wetting. Understanding these distinct material compositions and surface properties helps you select the appropriate membrane for applications requiring water permeability or water repellency.

Mechanisms of Water Interaction

Hydrophilic membranes attract and absorb water molecules due to their polar surface groups, allowing water to pass through via capillary action and hydrogen bonding. Hydrophobic membranes repel water, causing water to bead and remain on the surface, which prevents water penetration but allows air or vapor to pass. Your choice between these membranes depends on whether you need effective water permeability or waterproof separation in your application.

Common Applications of Hydrophilic Membranes

Hydrophilic membranes are widely used in water treatment processes, including ultrafiltration, microfiltration, and reverse osmosis, due to their high affinity for water and ability to effectively remove contaminants and suspended solids. These membranes excel in biomedical applications such as dialysis and sterile filtration, where they ensure efficient fluid passage while preventing bacterial penetration. Your choice of hydrophilic membranes can enhance performance in pharmaceutical production by maintaining product purity and consistent filtration quality.

Common Applications of Hydrophobic Membranes

Hydrophobic membranes are widely used in air filtration, gas-liquid separation, and membrane distillation due to their water-repellent properties that prevent membrane wetting and maintain permeability. Common applications include microporous filters for venting electronics, breathable waterproof fabrics, and membrane contactors in water treatment and industrial processes. Understanding the specific use of hydrophobic membranes can help you select the right material for applications requiring selective vapor transfer or gas flow control.

Advantages and Limitations of Each Membrane Type

Hydrophilic membranes excel in water permeability and fouling resistance, making them ideal for applications like water purification and biological treatments, but they are prone to swelling and structural degradation in harsh chemical environments. Hydrophobic membranes offer superior chemical resistance and are effective in gas separation and membrane distillation, yet they often suffer from lower water permeability and higher fouling tendencies when exposed to aqueous solutions. Your choice between hydrophilic and hydrophobic membranes should consider the specific operational conditions to maximize performance and lifespan.

Factors Affecting Membrane Selection

Membrane selection depends on factors such as the type of fluid being filtered, desired separation efficiency, and fouling resistance; hydrophilic membranes excel in treating aqueous solutions due to their affinity for water, reducing clogging and improving flux. Hydrophobic membranes are ideal for separating non-polar compounds or gases, providing better chemical resistance in oily or organic solvents. Your choice should consider operational conditions, chemical compatibility, and the specific application to optimize filtration performance and membrane lifespan.

Future Trends in Membrane Development and Usage

Future trends in membrane development emphasize enhancing hydrophilic membranes to improve water permeability and fouling resistance, driven by advances in materials like graphene oxide and zwitterionic polymers. Hydrophobic membranes are evolving with superhydrophobic coatings and nano-structured surfaces to boost oil-water separation efficiency and durability in harsh environments. Emerging applications in wastewater treatment, desalination, and bioprocessing stimulate the innovation of hybrid membranes combining hydrophilic and hydrophobic properties for multifunctional and energy-efficient performance.

Hydrophilic membrane vs hydrophobic membrane Infographic

libmatt.com

libmatt.com