Plug flow reactors (PFRs) provide a more efficient conversion for reactions with high reactant concentration gradients by maintaining a unidirectional flow and minimal backmixing, resulting in higher product yields for certain processes. Your choice between a PFR and a continuous stirred-tank reactor (CSTR) depends on the reaction kinetics, desired conversion, and mixing requirements, as CSTRs offer uniform composition and temperature but typically lower conversion per unit volume.

Table of Comparison

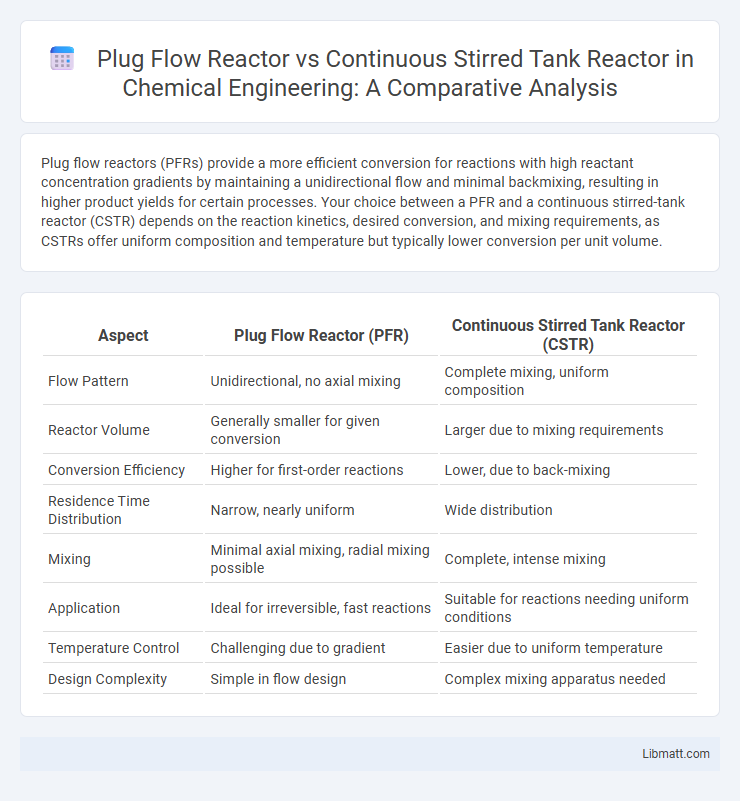

| Aspect | Plug Flow Reactor (PFR) | Continuous Stirred Tank Reactor (CSTR) |

|---|---|---|

| Flow Pattern | Unidirectional, no axial mixing | Complete mixing, uniform composition |

| Reactor Volume | Generally smaller for given conversion | Larger due to mixing requirements |

| Conversion Efficiency | Higher for first-order reactions | Lower, due to back-mixing |

| Residence Time Distribution | Narrow, nearly uniform | Wide distribution |

| Mixing | Minimal axial mixing, radial mixing possible | Complete, intense mixing |

| Application | Ideal for irreversible, fast reactions | Suitable for reactions needing uniform conditions |

| Temperature Control | Challenging due to gradient | Easier due to uniform temperature |

| Design Complexity | Simple in flow design | Complex mixing apparatus needed |

Introduction to Plug Flow Reactors and CSTRs

Plug flow reactors (PFRs) maintain a unidirectional flow where reactants move through the reactor as plugs with no back mixing, enabling predictable concentration gradients along the reactor length. Continuous stirred-tank reactors (CSTRs) provide complete mixing, resulting in uniform reactant concentration throughout the vessel and steady-state operation. Selecting Your ideal reactor depends on reaction kinetics and process requirements, with PFRs favoring plug flow dynamics and CSTRs suited for homogeneous mixing conditions.

Design Principles of Plug Flow Reactors

Plug flow reactors (PFRs) operate on the principle of ideal plug flow, where reactants move through the reactor as discrete "plugs" with no axial mixing and a concentration gradient along the reactor length. This design ensures high conversion efficiency, particularly for first-order reactions, by maintaining a continuous change in reactant concentration and temperature, optimizing reaction kinetics. Key design considerations include reactor length, diameter, and flow rate, which are carefully calculated to achieve desired residence time and minimize radial gradients.

Design Fundamentals of Continuous Stirred Tank Reactors

Continuous Stirred Tank Reactors (CSTRs) feature a well-mixed environment ensuring uniform composition throughout the reactor, allowing steady-state operation with continuous input and output streams. Their design fundamentals emphasize maintaining complete mixing to achieve consistent reaction rates and temperature control, often modeled using ordinary differential equations for reaction kinetics. Compared to Plug Flow Reactors (PFRs), CSTRs handle complex reaction systems with better control over residence time distribution but typically require larger volumes for the same conversion efficiency.

Flow Patterns: Plug Flow vs CSTR

Plug flow reactors (PFR) exhibit a flow pattern where fluids move in a streamlined, unidirectional manner with no mixing along the flow path, ensuring that fluid elements progress through the reactor at a uniform velocity. Continuous Stirred Tank Reactors (CSTR) maintain complete mixing within the reactor, resulting in uniform composition throughout and an outlet stream identical in concentration to the reactor contents. Your choice between PFR and CSTR depends on whether you require precise residence time control and minimal back-mixing (PFR) or enhanced mixing and homogeneity (CSTR) for your chemical process.

Residence Time Distribution Comparison

Residence Time Distribution (RTD) in a Plug Flow Reactor (PFR) is characterized by a nearly uniform residence time for all fluid elements, resulting in a narrow RTD and minimal back-mixing. In contrast, a Continuous Stirred Tank Reactor (CSTR) exhibits a broad RTD due to complete mixing, leading to significant dispersion of residence times within the reactor volume. Understanding these differences in RTD is crucial for optimizing reaction efficiency and selectivity in your industrial processes.

Conversion Efficiency: PFR versus CSTR

Plug flow reactors (PFR) typically achieve higher conversion efficiency than continuous stirred-tank reactors (CSTR) due to their idealized flow pattern, which minimizes back-mixing and maintains a concentration gradient along the reactor length. In PFRs, reactants experience increasing conversion as they move through the reactor, leading to higher overall conversion per reactor volume, especially for first-order reactions. Your choice between PFR and CSTR can significantly impact process optimization based on desired conversion efficiency and reaction kinetics.

Advantages of Plug Flow Reactors

Plug flow reactors (PFRs) offer superior conversion efficiency for reactions with high reactant concentration gradients due to their steady velocity profile and minimal back-mixing, ensuring each fluid element experiences the same reaction time. Their design enables better temperature control and reduced hot spots in exothermic reactions, enhancing safety and product selectivity. You benefit from higher throughput and improved catalyst utilization in applications demanding precise reaction conditions.

Benefits and Limitations of CSTRs

Continuous Stirred Tank Reactors (CSTRs) offer benefits such as uniform temperature and concentration throughout the reactor, facilitating efficient mixing and steady-state operation suited for liquid-phase reactions and large-scale industrial processes. Limitations include lower conversion per unit volume compared to Plug Flow Reactors (PFRs) due to back-mixing, which reduces reaction efficiency for fast or highly exothermic reactions. CSTRs also require careful control of residence time distribution to avoid issues with incomplete reactions and catalyst deactivation.

Industrial Applications: PFR vs CSTR

Plug flow reactors (PFRs) are ideal for continuous production processes requiring high conversion rates and are widely used in the chemical and petrochemical industries for reactions like polymerization and oxidation. Continuous stirred-tank reactors (CSTRs) excel in applications needing uniform product composition and temperature control, such as wastewater treatment and fermentation in biochemical industries. Choosing between a PFR and CSTR depends on your process requirements, including reaction kinetics, heat transfer, and product consistency.

Choosing the Right Reactor: Key Considerations

Selecting between a plug flow reactor (PFR) and a continuous stirred-tank reactor (CSTR) hinges on factors such as reaction kinetics, desired conversion rates, and mixing requirements. PFRs offer high conversion efficiency for first-order reactions due to their ideal plug flow pattern, making them suitable for fast reactions with minimal back-mixing. In contrast, CSTRs provide uniform composition throughout the reactor volume, ideal for slower reactions or those requiring constant temperature and thorough mixing to maintain reaction control.

Plug flow reactor vs CSTR Infographic

libmatt.com

libmatt.com