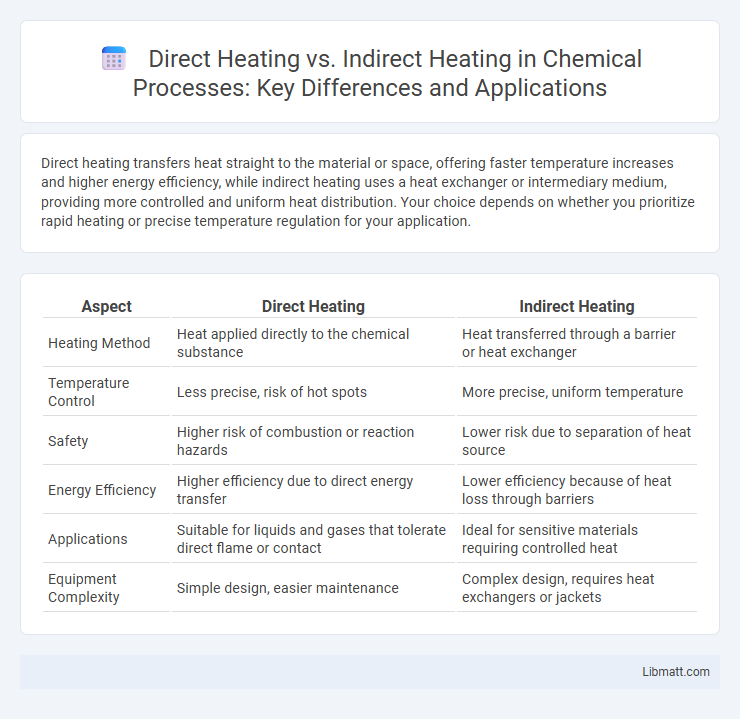

Direct heating transfers heat straight to the material or space, offering faster temperature increases and higher energy efficiency, while indirect heating uses a heat exchanger or intermediary medium, providing more controlled and uniform heat distribution. Your choice depends on whether you prioritize rapid heating or precise temperature regulation for your application.

Table of Comparison

| Aspect | Direct Heating | Indirect Heating |

|---|---|---|

| Heating Method | Heat applied directly to the chemical substance | Heat transferred through a barrier or heat exchanger |

| Temperature Control | Less precise, risk of hot spots | More precise, uniform temperature |

| Safety | Higher risk of combustion or reaction hazards | Lower risk due to separation of heat source |

| Energy Efficiency | Higher efficiency due to direct energy transfer | Lower efficiency because of heat loss through barriers |

| Applications | Suitable for liquids and gases that tolerate direct flame or contact | Ideal for sensitive materials requiring controlled heat |

| Equipment Complexity | Simple design, easier maintenance | Complex design, requires heat exchangers or jackets |

Introduction to Direct and Indirect Heating

Direct heating transfers heat through immediate contact between the heat source and the material, resulting in rapid temperature increase and improved energy efficiency. Indirect heating uses a barrier, such as a heat exchanger or heating element, to transfer thermal energy without direct contact, offering better control and reduced contamination risk. Understanding the differences helps you select the optimal heating method for applications like industrial processes, cooking, or HVAC systems.

Definition of Direct Heating

Direct heating involves transferring heat by direct contact between the heat source and the material, where the heat is applied instantly and efficiently. This method is commonly used in processes like gas stoves, furnaces, and industrial ovens, where flames or heated surfaces touch the target object directly. Your choice of heating depends on the speed and control required, with direct heating offering rapid temperature increases due to minimal heat loss.

Definition of Indirect Heating

Indirect heating involves transferring heat through an intermediate medium, such as steam, hot water, or heat exchangers, to the process material without direct contact with the heat source. This method ensures uniform temperature distribution, reduces contamination risks, and enhances safety in applications like chemical processing and food production. Indirect heating systems are commonly used in industries requiring precise temperature control and hygienic conditions.

Key Differences Between Direct and Indirect Heating

Direct heating transfers energy straight to the object or surface, resulting in faster temperature increases and higher efficiency for processes requiring immediate heat. Indirect heating uses a barrier, such as air or a fluid, between the heat source and the object, providing more uniform temperature control and reducing the risk of contamination. Your choice depends on the specific application, balancing speed and precision for optimal heating performance.

Advantages of Direct Heating

Direct heating offers rapid temperature increase by transferring heat straight to the target material, resulting in energy efficiency and reduced heat loss. This method simplifies system design with fewer components, leading to lower installation and maintenance costs. Enhanced process control and faster response times improve overall productivity and product quality in applications such as industrial dryers and furnaces.

Advantages of Indirect Heating

Indirect heating offers precise temperature control and uniform heat distribution, reducing the risk of scorching or overheating sensitive materials. It ensures safer operation by minimizing direct contact with the heat source, making it ideal for processes requiring consistent and gentle heating. Your equipment's longevity can improve due to less thermal stress and reduced potential for contamination.

Common Applications of Direct Heating

Direct heating is commonly used in applications requiring immediate and intense heat transfer, such as roasting, baking, and metal forging, where the heat source directly contacts the material. Industrial processes like glass melting and food processing also rely on direct heating for efficiency and precision. This method is favored in scenarios demanding rapid temperature changes and high energy efficiency.

Common Applications of Indirect Heating

Indirect heating is commonly used in applications requiring uniform temperature control, such as chemical processing, food pasteurization, and pharmaceutical manufacturing. Equipment like heat exchangers, jacketed vessels, and steam coils facilitate precise heat transfer without direct contact between the heat source and the product. Your choice of indirect heating ensures enhanced safety and product quality in sensitive industrial processes.

Energy Efficiency Comparison

Direct heating transfers energy straight to the target surface or space, resulting in minimal heat loss and higher energy efficiency compared to indirect heating systems, which first heat an intermediary medium like air or water. Indirect heating often involves additional energy losses due to heat exchange processes, insulation limitations, and longer heat transfer paths. Your choice of heating method directly impacts operational costs and environmental sustainability by influencing overall energy consumption efficiency.

Choosing the Right Heating Method

Choosing the right heating method depends on factors like energy efficiency, application type, and temperature control requirements. Direct heating delivers heat through direct contact with the heating element, making it ideal for rapid heating processes, while indirect heating uses a heat transfer medium, offering better temperature uniformity and safety for sensitive materials. Assess your specific needs to determine whether direct heating's quick response or indirect heating's precise control aligns with your operational goals.

direct heating vs indirect heating Infographic

libmatt.com

libmatt.com