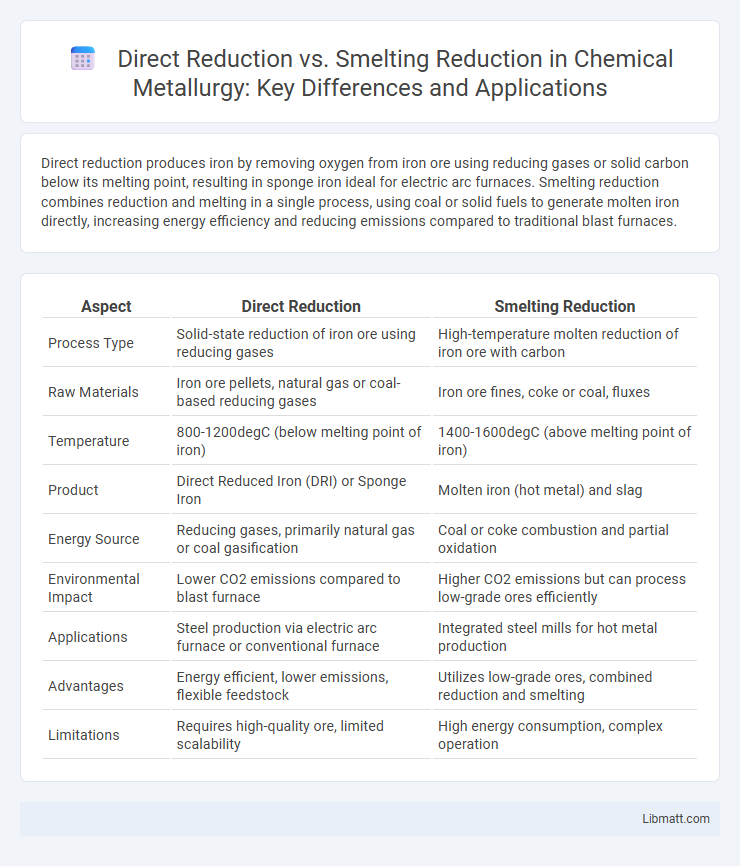

Direct reduction produces iron by removing oxygen from iron ore using reducing gases or solid carbon below its melting point, resulting in sponge iron ideal for electric arc furnaces. Smelting reduction combines reduction and melting in a single process, using coal or solid fuels to generate molten iron directly, increasing energy efficiency and reducing emissions compared to traditional blast furnaces.

Table of Comparison

| Aspect | Direct Reduction | Smelting Reduction |

|---|---|---|

| Process Type | Solid-state reduction of iron ore using reducing gases | High-temperature molten reduction of iron ore with carbon |

| Raw Materials | Iron ore pellets, natural gas or coal-based reducing gases | Iron ore fines, coke or coal, fluxes |

| Temperature | 800-1200degC (below melting point of iron) | 1400-1600degC (above melting point of iron) |

| Product | Direct Reduced Iron (DRI) or Sponge Iron | Molten iron (hot metal) and slag |

| Energy Source | Reducing gases, primarily natural gas or coal gasification | Coal or coke combustion and partial oxidation |

| Environmental Impact | Lower CO2 emissions compared to blast furnace | Higher CO2 emissions but can process low-grade ores efficiently |

| Applications | Steel production via electric arc furnace or conventional furnace | Integrated steel mills for hot metal production |

| Advantages | Energy efficient, lower emissions, flexible feedstock | Utilizes low-grade ores, combined reduction and smelting |

| Limitations | Requires high-quality ore, limited scalability | High energy consumption, complex operation |

Introduction to Ironmaking Technologies

Direct reduction and smelting reduction represent two innovative ironmaking technologies designed to produce iron more efficiently while reducing environmental impact. Direct reduction involves converting iron ore into solid metallic iron using reducing gases or coal-based fuels at lower temperatures, which preserves energy and lowers CO2 emissions. Smelting reduction integrates reduction and melting in a single reactor, enabling the use of non-coking coal and lower-grade ores, optimizing Your iron production process with enhanced resource flexibility.

Overview of Direct Reduction

Direct reduction is a process that converts iron ore into metallic iron using a reducing gas or solid carbon without melting the iron, maintaining it in a solid-state form called direct reduced iron (DRI). This method operates at lower temperatures compared to smelting reduction, resulting in less energy consumption and lower greenhouse gas emissions. Your choice of direct reduction can improve energy efficiency and reduce environmental impact in iron and steel production.

Overview of Smelting Reduction

Smelting reduction is a high-temperature process that converts iron ore directly into molten iron by reducing oxides using a carbon-based reducing agent in a furnace, bypassing the need for coke production. This method integrates reduction and melting in a single step, enhancing energy efficiency and allowing the use of lower-grade iron ores and non-coking coals. Smelting reduction technologies, such as COREX and FINEX, are increasingly adopted for their environmental benefits and potential to reduce CO2 emissions compared to traditional blast furnace routes.

Key Process Differences

Direct reduction involves the chemical removal of oxygen from iron ore using reducing gases such as hydrogen or carbon monoxide at lower temperatures, resulting in solid sponge iron. Smelting reduction combines the reduction and melting steps by injecting fuels and fluxes into a molten slag-metal bath, producing liquid iron directly. These key process differences impact energy consumption, product form, and equipment requirements in ironmaking operations.

Raw Material Requirements

Direct reduction primarily uses iron ore pellets or lump ore and requires natural gas or coal gas as the reducing agent, which results in lower raw material costs and carbon emissions compared to smelting reduction. Smelting reduction demands a blend of iron ore fines, coal, and fluxes like limestone, making its raw material requirements more complex and energy-intensive. Your choice between these methods depends on raw material availability, cost-efficiency, and environmental considerations.

Energy Consumption Comparison

Direct reduction processes consume significantly less energy than smelting reduction methods by utilizing natural gas or reducing gases at lower temperatures, resulting in reduced fuel requirements. Smelting reduction relies on high-temperature melting of iron ore using coal or coke, leading to higher overall energy consumption and carbon emissions. Your choice between these technologies directly impacts operational energy efficiency and environmental footprint in steel production.

Environmental Impact Assessment

Direct reduction produces fewer greenhouse gas emissions compared to smelting reduction due to its lower energy consumption and reliance on natural gas instead of coal. Smelting reduction emits larger amounts of CO2 and pollutants because it uses coke and coal as primary reductants in high-temperature furnaces. Environmental Impact Assessments highlight direct reduction as the more sustainable technology with reduced air pollution and lower carbon footprint in steel production.

Product Quality and Applications

Direct reduction produces high-quality sponge iron with low impurities, ideal for electric arc furnace steelmaking focused on superior steel grades. Smelting reduction yields molten iron suitable for integrated steel plants, often with variable impurity levels depending on feedstock and process control. Your choice depends on the desired final product quality and specific application in steel production.

Economic Considerations

Direct reduction processes typically offer lower energy consumption and reduced carbon emissions compared to smelting reduction, making them economically favorable in regions with high energy costs or stringent environmental regulations. Smelting reduction often requires higher capital investment and operational costs but enables higher throughput and utilization of lower-grade ores. Economic viability ultimately depends on factors such as raw material prices, energy tariffs, infrastructure availability, and market demand for specific steel grades.

Future Trends in Reduction Methods

Future trends in reduction methods emphasize the shift toward more sustainable and energy-efficient processes, with direct reduction gaining prominence due to its lower carbon footprint compared to traditional smelting reduction. Innovations in hydrogen-based direct reduction aim to replace natural gas, significantly reducing CO2 emissions in steel production. Your choice between direct reduction and smelting reduction will increasingly depend on environmental regulations and the availability of green energy sources.

Direct reduction vs smelting reduction Infographic

libmatt.com

libmatt.com